VPI Industries will be well known to many people into music particularly vinyl, for those new to them, the company is a leader in the field of record cleaning machines and award-winning turntables. VPI Industries recently joined the growing number of companies using 3D printing as a manufacturing method for their products with a 3D printed turntable tonearm.

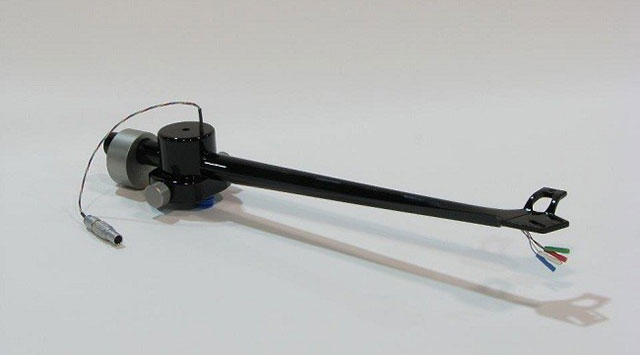

Last year the company started to develop a new direct drive turntable, but instead of using an aluminum tonearm, VPI produced the world’s first synthetic 10-inch tonearem – using a 3D printer and a little help from a Pennsylvanian design company.

Tonearm is a one-piece structure, from its head shell to its counterweight stub. It’s manufactured from an epoxy-plastic that is incredibly lightweight and rigid. VPI plans to make the tonearm available in 9-inch, 10-inch, and 12-inch options for its own tables and those of others.

Digital Trends’ Ian White was invited to a private listening session at VPI Industries where they showcased the new 3D printed tonearm created tunes installed on a new Classic Direct turntable with a $220 Grado Gold phono cartridge. VPI Industries’ CEO, Harry Weisfeld, demonstrated the same five records on a VPI Classic 3 turntable using a standard metal tonearm paired with an $8000 German manufactured Clearaudio cartridge for comparison purposes.

The new 3D printed tonearm with $220 cartridge put up a good fight, before finally going down on points, but the take out from this was that the decision wasn’t easy, and that the tonearm/table combination definitely made a huge impact on the sound quality, but the impact of the 3D printed tonearm was massive.

Will tonearms be manufactured using 3D printing from now on? Perhaps the time isn’t upon us yet. Cost and lead time is still a major limitation for 3D printing tonearms, compared compared with traditional manufacturing techniques; it wouldn’t be profitable for VPI to provide 3D printed tonearms. The 3D printing tonearm took 24 hours, but surely as new and more efficient 3D printing technologies evolve, 3D printing tonearms could well be a reality soon.

Source: Digital Trends