A new 3D printing discovery at Virginia Tech is poised to change the way we design sensors and low-power generators.

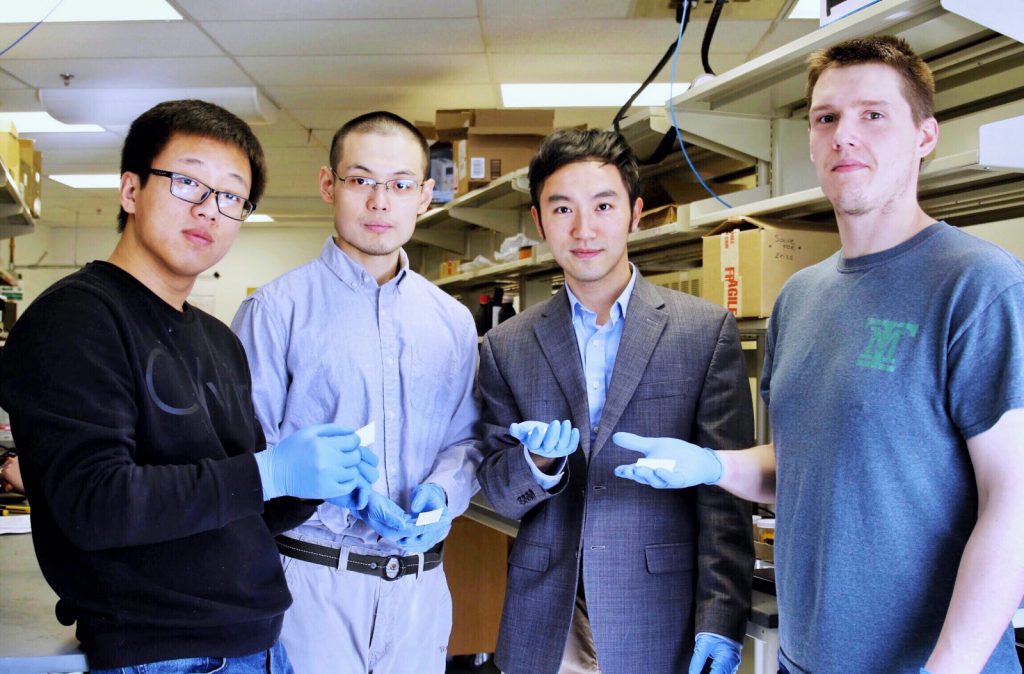

A team lead by associate professor Xiaoyu ‘Rayne’ Zheng has succeeded in creating piezoelectric structures that can take on any shape or form. By enabling such flexibility, the researchers are now free to create a range of objects capable of generating electricity, monitoring impact, or sensing the environment around them, without the use of multiple leads or connectors.

Huachen Cui, a doctoral student under Zheng and first author named on a study detailing the discovery explains, “Traditionally, if you wanted to monitor the internal strength of a structure, you would need to have a lot of individual sensors placed all over the structure,”

“Here, the structure itself is the sensor – it can monitor itself.”

Generating electricity with ceramics and crystals

Piezoelectricity is the electric charge that occurs in certain ceramic and crystalline materials when stress or strain is applied. One common example application of piezoelectric materials is quartz wristwatches.

In a quartz watch a small electric charge is supplied to a quartz crystal by the battery. This causes the crystal to vibrate, and the rate of vibration translates to a movement of the hands (ticking) to keep time.

Piezoelectricity is also harnessed in some inkjet printheads, for precise droplet deposition, or “droplet on demand” technology.

The materials used to generate piezoelectricity however are inherently brittle. They require controlled, clean-room environments for manufacturing, and the materials’ atoms are typically fixed, making them unsuitable for shaping into flexible structures.

Programmable materials

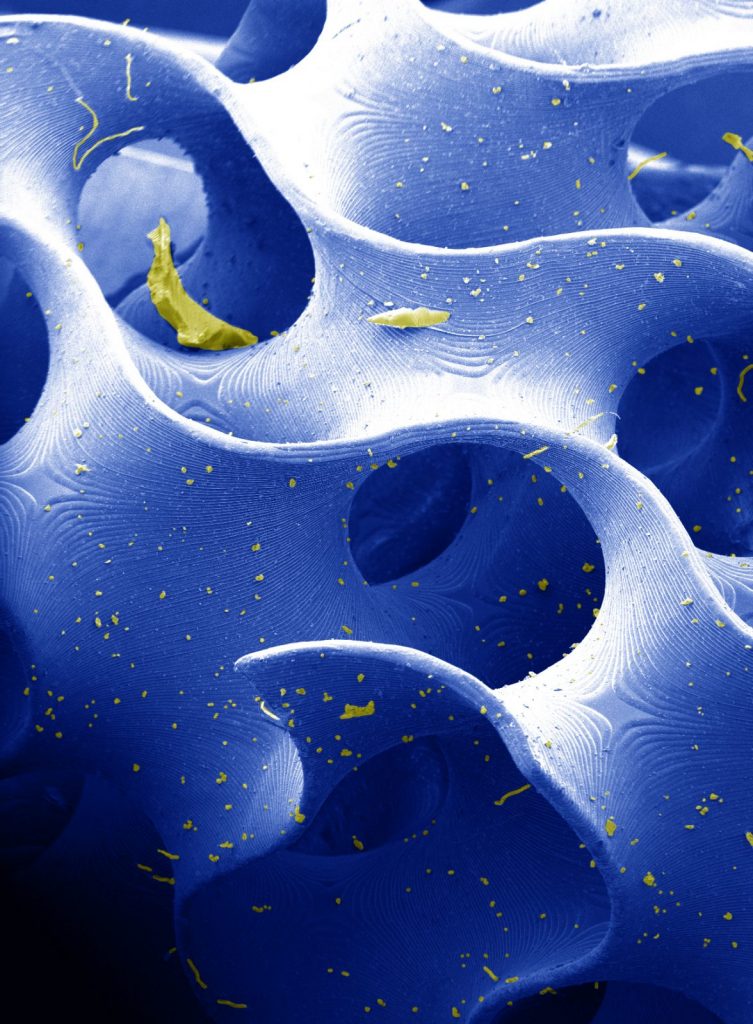

To overcome the fabrication challenges of piezoelectric materials, the Virginia Tech team have formulated an ink made from nanocrystals and a UV-sensitive gel. Zheng explains, “We have synthesized a class of highly sensitive piezoelectric inks that can be sculpted into complex three-dimensional features with ultraviolet light.”

Through experimentation with these inks, and the 3D printing process, the team have discovered how to precisely tune the material to achieve a desired result.

“By programming the 3D active topology,” Zheng adds, “you can achieve pretty much any combination of piezoelectric coefficients within a material, and use them as transducers and sensors that are not only flexible and strong, but also respond to pressure, vibrations and impacts via electric signals that tell the location, magnitude and direction of the impacts within any location of these materials.”

3D printed as a thin gauze or stiff block of material, the researchers are now focusing on real-world applications for piezoelectric lattices. For example, Zheng says, “We have a team making them into wearable devices, like rings, insoles, and fitting them into a boxing glove where we will be able to record impact forces and monitor the health of the user.”

Some of the team’s current work with the piezoelectric ink is demonstrated in the video below.

A full paper discussing the research detailed in this article is published in Nature Materials, titled “Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response.” The research is co-authored by Huachen Cui, Ryan Hensleigh, Desheng Yao, Deepam Maurya, Prashant Kumar, Min Gyu Kang, Shashank Priya and Xiaoyu (Rayne) Zheng.

Is this your Research Team of the Year? Nominate Virginia Tech, or another institute, for the 2019 3D Printing Industry Awards.

For more 3D printing research updates subscribe to the free 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter. Consider 3D Printing Jobs for your next research opportunity.

Featured image shows a piezoelectric 3D printed lattice. Photo via Virginia Tech