UK-based 3D printing software company Valuechain has integrated Israeli start-up PrintSyst’s AI-Perfector engine into its DNA.am MES platform.

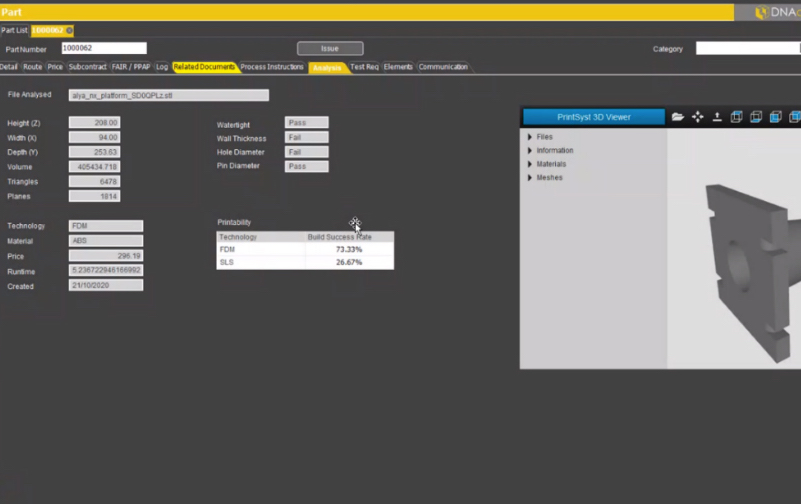

The upgraded system is able to automatically set a part’s print parameters based on the standards of its target industry, while recommending the ideal material for its functional needs. By further automating the pre-printing process, Valuechain’s software could enable clients in the automotive, aerospace and defense sectors to scale their production workflow.

“Combining our world class AI engine and hands on industry experience, with DNA.am’s leading industrial-grade MES, will step change the manual, costly and unscalable 3D printing workflow,” said Itamar Yona, CEO of PrintSyst. “We are now able to take into account multiple additional parameters that exist in DNA.am and automatically train our engine.”

PrintSyst’s algorithm-driven automation

Established in 2017, PrintSyst is a company that’s dedicated to automating and optimizing the pre-printing process. The firm launched its AI-Perfector program earlier this year, featuring ML algorithms that use previous data to make parameter suggestions, and ultimately reduce the amount of trial and error during production.

Valuechain’s DNA.am subsidiary, meanwhile, has developed a self-titled process management platform in partnership with Airbus UK. In 2018, Valuechain was awarded a £960k grant from Innovate UK to further develop the software, and it used the some of the funding to set up a new testing facility at its Lancashire HQ.

The DNA.am program features inventory, quality and chemical management tools that are each designed to streamline the production workflow for its users. PrintSyst and DNA.am initially partnered to co-develop an AI-engine that focuses on data capture and traceability in 2019, and it now appears to have come to fruition.

Valuechain’s new AI-driven offering

Having integrated PrintSyst’s software into its DNA.am program, Valuechain will now be able to offer its clients an AI-enhanced product. The upgraded software learns from previous builds, and ensures the compliance of parts with industry standards, making it ideal for manufacturing in the heavily-regulated aerospace sector.

Valuechain’s enhanced program makes suggestions based on the print’s success probability and material compatibility, which could help users to improve their part quality. DNA.am’s parameters also train the AI algorithm to provide personalized set-ups, enabling the clients of both firms to increase their productivity.

According to Tom Dawes, CEO of Valuechain, the COVID-19 pandemic has created new opportunities for both 3D printing, and the company’s new AI-boosted MES software. “Industrial 3D printing has continued to grow over recent months, as companies that initially trialled the technology are looking to scale up,” said Dawes.

“COVID-19 has illustrated the importance of a robust supply chain structure, underpinned by secure collaboration and intelligence,” he added. “Based on our customers’ feedback so far, I am confident that our collaboration with PrintSyst will be pivotal in addressing this critical need.”

AI algorithms in the 3D printing industry

Companies have increasingly turned to the ML capabilities of AI algorithms, as they seek to drive maximum efficiency from their 3D printing production processes.

TOffee AM offers one such solution in the shape of its topology optimization software, which it claims can produce parts 20 times faster than conventional processes. The company recently gained $1 million in funding, with which it plans to use on expanding its engineering capabilities and its client base.

Elsewhere, Metal and 3D printer manufacturer Markforged has launched a new ML-driven 3D printing software platform called the Digital Forge. The company’s Eiger software constantly learns from its fleet of 12,000 systems, theoretically making each print more accurate than the last.

Machine learning has also been applied within military applications, and the US Army Research Laboratory (ARL) recently agreed to use Senvol’s software to develop 3D printed missile parts. The overall aim of the partnership is to create a ‘qualification plan,’ that can be applied to any additive manufacturing method.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows PrintSyst’s Itamar Yona and Valuechain’s Tom Dawes shaking hands. Photo via PrintSyst.