Israeli 3D printing software startup Printsyst and UK based software company DNA.am are partnering to develop an AI platform for additive manufacturing in the aerospace sector. Funded by a £600k grant from Innovate UK and the Israel Innovation Authority, the project seeks to help aerospace manufacturers scale-up and improve the productivity of their 3D printing processes.

“In our experience, AM organisations are unfamiliar with best practice AM workflows and the many parameters required for 3D Printing optimization, such as geometry, material or which AM technology to select,” commented Printsyst CEO, Itamar Yona.

“Our solution will accurately estimate AM component costings and eliminate need for trial and error, which will ultimately transform AM productivity through improved quality, cost and delivery responsiveness.”

An automatic start for 3D printing

Founded in 2017, Printsyst has developed software that aims to streamline the print preparation workflow. The program integrates CAD design, object detection, automatic file repair, slicing, and troubleshooting into one system, making it easier to start 3D printing. Currently, in the beta stages, Printsyst software is available as a free trial. It will form the basis of AI capabilities for the new platform developed in collaboration with DNA.am.

Creating tangible returns for aerospace additive manufacturing

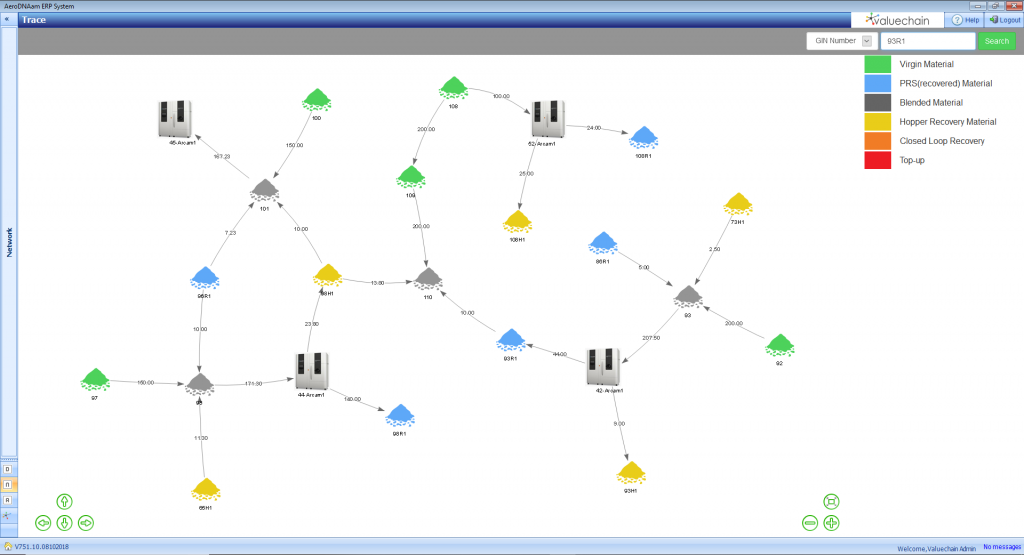

The software was initially developed by manufacturing software company Valuechain and DNA.am is a subsidiary of the company. DNA.am’s main product is a self-titled additive manufacturing process management and monitoring software developed in collaboration with Airbus UK. In 2018, parent company Valuechain was awarded a £960k grant by Innovate UK to further develop this program, and establish an innovation center for testing at its Lancashire HQ. One of the features of DNA.am software includes an ability to capture and record the chemical composition of materials used in the process. With it, users also have the ability to manage inventories and make records for quality control.

“By combining DNA.am’s streamlined data capture and aerospace traceability with Printsyst’s AI optimization engine,” comments Tom Dawes, Chairman of Valuechain, “we are confident that our integrated solution will standardize best practice processes for growing companies and accelerate AM adoption in the aerospace sector and other highly regulated sectors.”

With these abilities, the partners hope to overcome the challenges faces by aerospace manufacturers integrating 3D printing into existing production. Dawes adds, “Aerospace companies continue to invest heavily in AM plant[s], but are yet to implement smart solutions that optimize plant and resource efficiencies,”

“Driving AM productivity and generating tangible return on investment has to be the priority for the AM ecosystem.”

The first prototypes of this project from Printsyst and DNA.am will be exhibited at Formnext 2019.

For more of the latest 3D printing applications subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Create a profile on 3D Printing Jobs, or advertise for free to recruit additive manufacturing experts.

Featured image shows, from left to right, Itamar Yona, Printsyst Ltd. CEO and Tom Dawes, Valuechain and DNA.am Ltd. Chairman. Photo via Printsyst