A research team from the US Air Force (UAF) has successfully produced a surgical retractor using 3D printing.

The medical instrument, created a desktop 3D printer, is designed to be used in logistically challenging hostile environments where it is not possible to restock medical supplies using conventional methods.

It has been produced as a proof of concept, with the aim of establishing a digital library of 3D files, which could be used to produce 3D medical instruments. This would enable deployed medical personnel to download and produce a range of medical equipment, on-demand, anywhere in the field.

The “Air Force” retractor

A surgical retractor is an instrument used by field doctors to separate the edges of a wound or incision, in order to conduct surgery on an injured body part or limb. In what the US military describes as an anti-access or area denial (A2/AD) region, the dangers necessitate the need for such medical tools to be readily available.

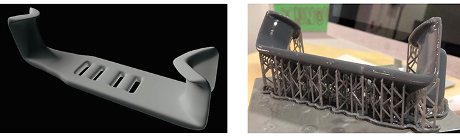

The 3D printed retractor is therefore designed with field use in mind. It consists of two parallel blades of different sizes, with one designed for narrow wounds, and the other for cases requiring broader access. It has downward-angled curved blades at each end to facilitate entry and instrumentation, which has earned it the nickname of the “Air Force Retractor,” due to the similarity of the retractor blades to the swept wings of fighter aircraft.

The device was produced using a Formlabs Form2 3D SLA printer with grey resin, which is general-purpose and often used for prototyping. In order to gain FDA approval, the instruments will need to be produced on resins that can be sterilized, and Formlabs offers several photopolymer resins with potential medical applications. Dental SG Resin is a durable biocompatible material for dentistry, has been identified as a strong and durable enough biocompatible material, and the team intends to use it in future iterations.

Using the free online design tools provided by Tinkercad and Blender to create and modify the 3D file for the project, the team were able to produce the instruments with no formal training, and without incurring the associated training costs. These programs prepared the 3D model for printing, ensuring that the scaling, resolution, and orientation of the model were correct, and added supports during the printing process where necessary.

The next step for the program is to attempt to patent the technology and gain FDA approval to produce the instruments using stainless steel and a radiolucent polymer. The team ultimately aims to replicate the results of a different study, in which a spine localizer was 3D printed and assembled at a medical facility, by either establishing an online repository or creating locally stored files to produce other medical devices on demand.

The research team acknowledged that challenges exist to this strategy including production time, portability of the 3D printers, limits to the size of the instruments produced, and training required to use the printers. However, they remain confident that the technology could be used to replenish supplies within hours, or even create novel products such as prosthetics if the need should arise.

The findings of the project are detailed in a paper titled “An Example of 3-D Printing for Expeditionary Medicine: The Air Force Retractor,” which was published in the Military Medicine journal. It is co-authored by James A Chambers, Kenneth P Seastedt, and Jocelyn Raymundo-Grinstead.

The US Air Force and 3D printing

The US Air Force has consistently invested in experimental new applications of additive manufacturing technology as a means of reducing the cost and lead times of equipment.

Last February for example, the US Air Force awarded Sciperio, a Florida-based research group, Phase II funding to develop 3D printed phased array antennas. The funding was used to develop Sciperio’s Factory in Tool system (FiT), in order to manufacture custom-shaped antennas for US Air Force UAVs and aircraft. The system, a multiple tool head manufacturing machine, is used to manufacture miniature phased array antennas on customized surfaces. These are then mounted to a UAV or aircraft as part of its structure rather than as a separate system, which minimizes expenditure.

America Makes, the Ohio-based AM accelerator company, also worked with the UAF last year to produce 3D printed low-cost replacement parts for legacy aircraft. As part of the three-phased Maturation of Advanced Manufacturing for Low-cost Sustainment (MAMLS) project, the Department of Defence granted America Makes over $9 million in funds to oversee its completion.

The UAF also plans to take part in an upcoming Advanced Manufacturing Olympic Event later this year, competing in design challenges with additive manufacturing companies, defense contractors, tech startups, and universities. The Air Force aims to use the event to test the capabilities of its 3D printed components, and expand the manufacturing sources of its supply chain. The event has been delayed from July 7th 2020, and is now scheduled to take place on November 16th 2020.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Capt. Erin Hager analysing the porosity of a 3D printed part. Photo via Air Force Institute of Technology.