Engineered materials company Uniformity Labs, has announced the availability of its UniFuse 316L ultra-low porosity stainless steel powder

The company claims this high throughput feedstock exhibits “best-in-class material properties.” Various industries have created large-scale parts using UniFuse 316L powder and optimized print processes.

“Our powders deliver superior mechanical properties, surface finish, printing yield, and part reliability, and allow one machine to do the work of several,” said Adam Hopkins, Uniformity founder and CEO.

Features of UniFuse 316L 90um stainless steel powder

Uniformity claims that UniFuse 316L 90um 400W Performance mechanical properties outperform industry-standard lower layer thickness parameter sets in UTS, YS, elongation, and density. Furthermore, Uniformity Labs UniFuse 316L ultra-low porosity powder and High-Performance Scanning (HPS) promises a 3X faster build time with lower layer thickness scan techniques aiming for ideal mechanical properties. This increase in throughput is customary for UniFuse 316L builds. When compared with similar layer thickness builds, Uniformity Labs UniFuse 316L and HPS attain improved mechanical properties and build uniformity throughout the build platform while enhancing throughput.

Uniformity powders deliver enhanced mechanical properties and reliability across the build bed, even at increased build rates and thicker layer printing, thanks to higher bed and tap densities.

316L is austenitic stainless steel ideal for parts subjected to marine, pharmaceutical, or petrochemical processing, food preparation equipment, medical devices, surgical tooling, and consumer products such as jewelry. It is recognized for its resistance to corrosion, high flexibility, and what the company describes as “excellent mechanical properties” at high temperatures.

“The application of Uniformity 316L 90um stainless steel delivers mechanical excellence for our customers who require materials that perform to the highest standard in extreme conditions,” added the Uniformity founder and CEO.

The recurrent flow of metal powders in additive manufacturing

A novel Additive Manufacturing Suitability (AMS) factor which can rate the printability of metal powders for laser powder bed fusion (LPBF) processes was previously proposed in a research conducted by the Ecole de Technologie Superieure in Montreal, Canada, and a separate industrial cluster. Both studies used the Freeman Technology FT4 Powder Rheometer to evaluate the dynamic, shear, and bulk characteristics of powders and mix them into a single metric. According to the researchers, this metric, the AMS factor, can then distinguish printability in a manner that traditional powder testers cannot.

Furthermore, industrial 3D printing materials manufacturer 6K Additive, announced the commercial release of a novel set of refractory metal powders for additive manufacturing. Refractory metals are a type of material distinguished by its high heat and wear resistance. They all have similar properties, such as melting points above 2000°C and exceptional room temperature hardness. They’re also unreactive and have high densities, making them ideal for high-stress parts.

Elsewhere, EOS, the global leader in LB-PBF systems, enlarged its AM material offering by introducing eight novel metal powders and processes for use with its M 290, M 300-4, and M 400-4 3D printing systems. This material set includes one PREMIUM and seven CORE products that are distinguished by their Technology Readiness Levels (TRLs) – an EOS material and process technological maturity classification system launched in 2019. The TRL system’s goal is to help manufacturers safely cross the border into serial AM production by providing a standardized, data-backed metric.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

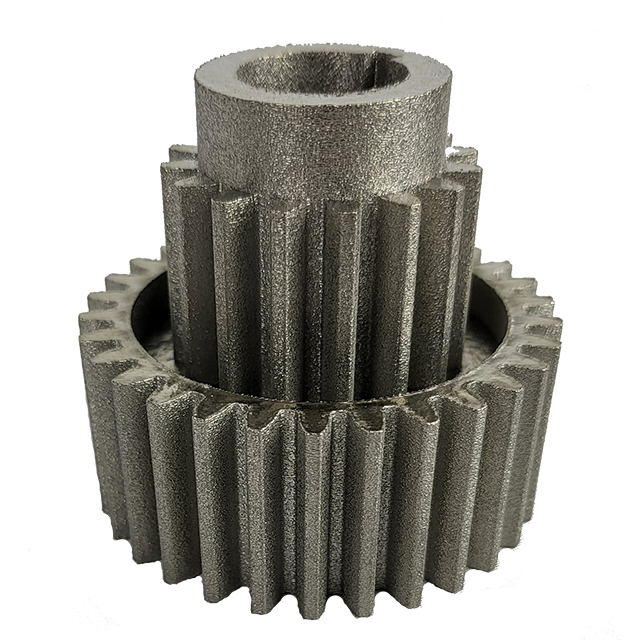

Feature image shows a part 3D printed using UniFuse 316L 90um stainless steel powder. Image via Uniformity Labs.