6K Additive, a producer of industrial materials for the 3D printing sector, has announced the commercial launch of a new set of refractory metal powders for additive manufacturing.

Refractory metals are a special class of material characterized by their excellent heat and wear resistance. They all share a similar set of properties, including melting points of above 2000°C and exceptional hardness at room temperature. They’re also chemically inert and have relatively high densities, making them suitable for high stress parts.

The new offering, produced using the company’s proprietary UniMelt plasma system, includes high-value metals such as tungsten, rhenium, and niobium-based alloys. 6K Additive hopes to target the defense, aerospace, and medical sectors with its new product range, where such materials are often used for high-temperature and high-strength applications.

Frank Roberts, President of 6K Additive, said, “The leading defense organizations are not only looking for refractory materials like tungsten and rhenium, they’re looking for it at production scale. The uniqueness of 6K’s UniMelt microwave plasma process, combined with the expertise of our operations team, has allowed us to manufacture production scale volumes for many of the refractory powders like tungsten and tungsten/rhenium.”

The UniMelt microwave plasma system

6K’s microwave plasma powder production process is capable of turning machined millings, turnings, and other recycled waste into industrial-grade 3D printing powders. Based on this process, the company’s UniMelt system is used to produce a whole host of materials such as Onyx In718, Onyx Ti64, ferrous alloys, cobalt-based alloys, nickel superalloys, refractory metals, and even high-temperature ceramics. Additionally, the system features a highly precise plasma zone with zero contamination.

Roberts adds, “We have now spheroidized the full spectrum of refractory powders including tantalum, niobium, and molybdenum and we are ready to help organizations advance their applications with these materials.”

Back in 2020, 6K Additive completed work on a 45,000 sq/ft powder manufacturing plant in Burgettstown, PA. The facility was fitted with two UniMelt systems, with two more scheduled for installation at the end of this year. 6K will also begin expanding the powder production building in the next few months to make space for six additional UniMelt systems which will be fitted throughout 2022. The two systems currently in place are capable of deliver a total of 200 tons of feedstock powder per year.

More recently, 6K’s energy division, 6K Energy, also announced the establishment of a new Center of Excellence. The 33,000 sq. ft. state-of-the-art facility will repurpose the firm’s UniMelt technology to develop new sustainable battery materials for energy storage devices. Targeting electric vehicles (EV), grid storage, and consumer goods, the company is set to invest $25 million over the next few years into the factory.

Tungsten-rhenium powder for aerospace

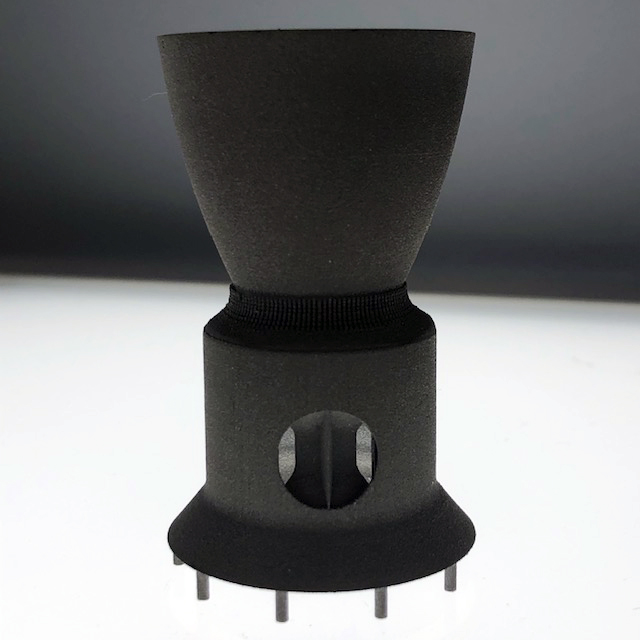

Prior to the commercial launch, some of 6K’s customers already started making use of the new refractory metal offering. Quadrus Corporation, an engineering service provider based in Alabama, recently enlisted the help of 6K Additive’s expert services to produce a spherical tungsten-rhenium powder.

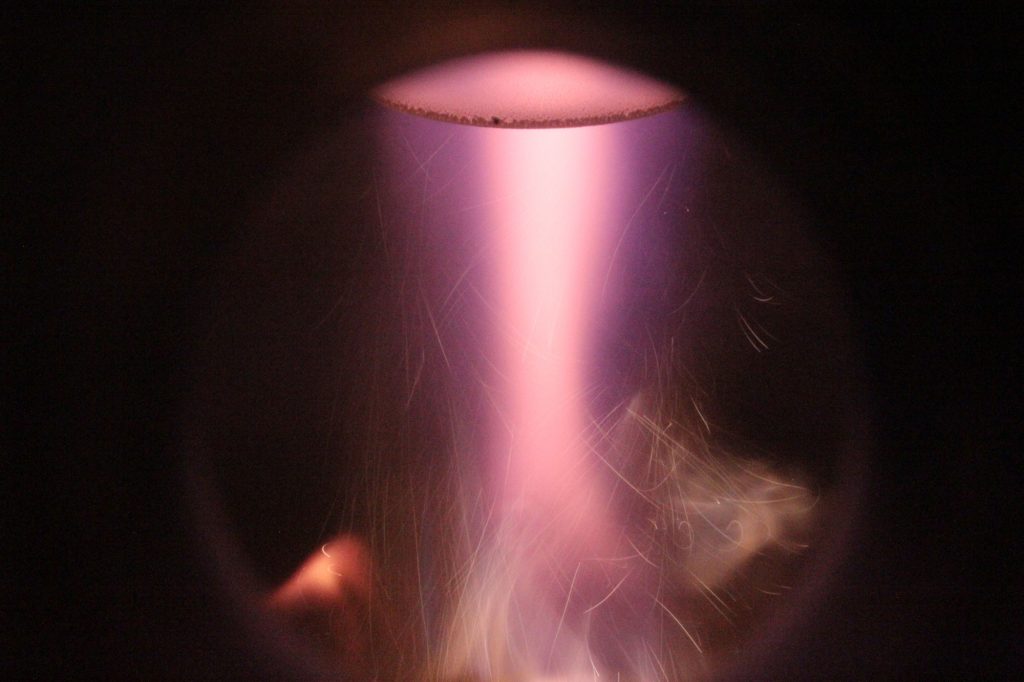

The material was used to 3D print a non-eroding throat insert for a solid rocket motor nozzle – an application that relied largely on the high-temperature, high-strength nature of the material. Additionally, the tungsten-rhenium powder spheroidized by 6K was found to process ‘exceptionally well’ on the company’s in-house SLM 3D printers.

Joe Sims, Director of the Quadrus Advanced Manufacturing Division, added, “Having a reliable, trusted supply chain partner like 6K Additive for refractory materials is critical to our business and to our defense customers. Our powder quality requirements are extremely high and 6K Additive easily cleared that hurdle for us.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a non-eroding throat insert for a solid rocket motor nozzle 3D printed using tungsten-rhenium. Photo via 6K Additive.