New research conducted by the Ecole de Technologie Superieure in Montreal, Canada, and a separate industrial cluster, has proposed a new Additive Manufacturing Suitability (AMS) factor that can rank the printability of metal powders for laser powder bed fusion (LPBF) processes.

Both sets of research leveraged the FT4 Powder Rheometer from micromeritics firm Freeman Technology to measure the dynamic, shear and bulk properties of powders and combine them into a single metric. This metric, the AMS factor, is then able to differentiate printability in a way that conventional powder testers cannot, according to the researchers.

“Many in the AM community, from powder and machine suppliers to end-users, would like to be able to reliably test a powder for printability, said Jamie Clayton, Operations Director at Freeman Technology.

“Work such as this demonstrates progress towards this goal, emerging consensus with respect to the need to measure multiple parameters, and the value of dynamic flow properties.”

Improving LPBF 3D printing

Over the last few years, researchers and industry players alike have boosted efforts to improve and enhance the LPBF 3D printing process in order to avoid defects in metal printed parts. According to leading additive manufacturing experts, the future of 3D printing is likely to see increasing progress in this area going forwards.

Such attempts have involved the use of LEDs instead of lasers to melt powder, the development of “smart” baseplates, and better balancing heat within the build chamber to reduce a component’s residual stress and distortion.

In September last year, scientists at Texas A&M University furthered this work through the introduction of a universal method to 3D print flawless metal parts via LPBF using single-track printing data and machine learning. Meanwhile, researchers at Lawrence Livermore National Laboratory (LLNL) revealed their plans to explore alternative laser beam shapes to the Gaussian beams commonly used in LPBF, with the aim of reducing porosity and defects in metal parts.

Now, the latest research in the area of LPBF printing is seeking to answer the question “Can I print with this powder?”, and aid firms and individuals in their metal powder selection.

The AMS factor

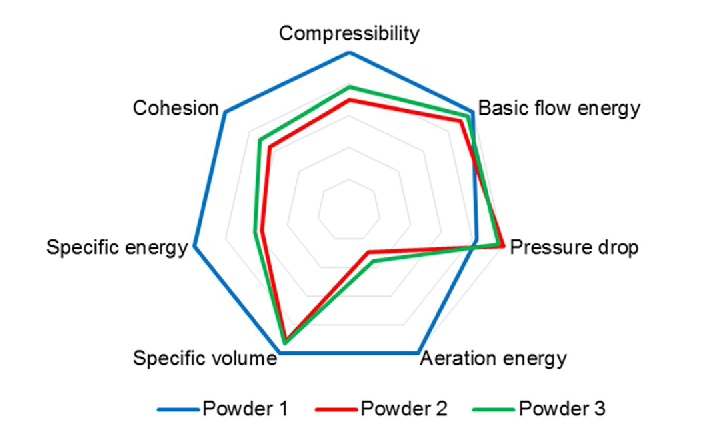

Freeman Technology’s FT4 Powder Rheometer is a universal powder flow tester for measuring powder flow properties and behavior. Initially designed to characterize the rheology of powders and powder flow properties, the FT4 has been developed into a ‘universal powder flow tester’ with three main abilities.

The first of these abilities is to simulate powder processing conditions, the second is to apply multi-faceted powder characterization to assess dynamic powder flow, bulk, and shear properties, and the third is to enable the differentiation of powders that other testers classify as identical.

The printability of 3D printing powders is often assessed through print trials due to the difficulty of establishing a relevant specification, however this is a time-consuming, inefficient, and costly process. To address this, researches at the Ecole de Technologie Superieure leveraged the FT4 to rank the processability of Ti-6Al-4V powders by combining the tester’s multiple measurements into a single metric, the AMS factor. The resulting AMS value was then correlated with the powder’s print performance.

According to the researchers, traditional powder testing techniques, such as flow through an orifice or tapped density methods, proved unable to provide sensitive and relevant differentiation in comparison to the AMS factor.

A second research group formed of industry partners later built on this concept. They used a modified AMS factor to successfully assess the processability of metal powders for in-situ alloying within an LPBF 3D printing process.

“We’re delighted that the FT4 can successfully rank print performance,” said Clayton. “For us powder testing is all about improving process efficiency and product performance and this is a great example of it doing just that.”

Further information on the studies referenced can be found in paper titled: “Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy,” published in the Additive Manufacturing journal and co-authored by S. Brika, M. Letenneur, C. Dion, and V. Brailovski, and also in the paper titled: “In situ alloying in powder bed fusion: The role of powder morphology,” published in the Materials Science and Engineering journal and co-authored by M. Knieps, W. Reynolds, J. Dejaune, A. Clare, and A. Evirgen.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

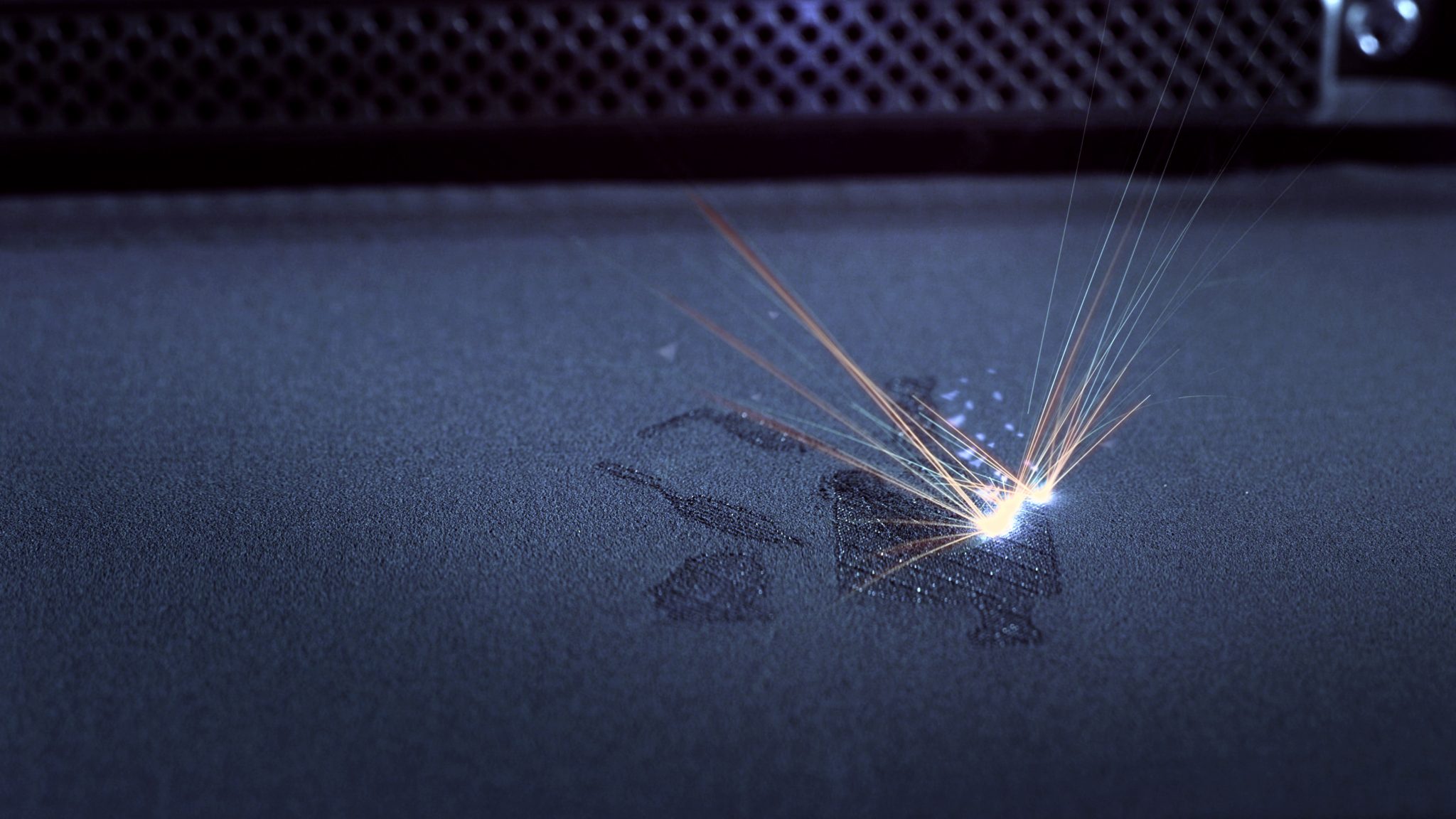

Featured image shows new research establishes the concept of an ‘AM Suitability’ factor for metal powder selection. Image via Freeman Technology.