Scientists from the University of Leeds and University of Edinburgh have 3D printed a synthetic tongue, which could be capable of sensing flavors in food.

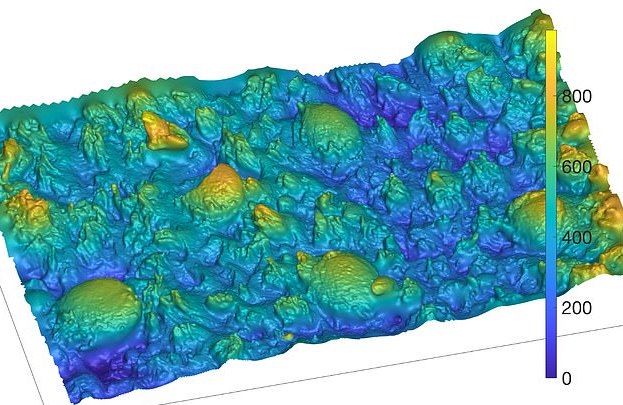

The researchers created their soft biomimetic device by 3D printing ‘papillae’ (or taste buds) similar to those found in the authentic organ, onto a silicone elastomer using a point process-based model. Utilizing their additive dorsum, which emulated the texture of the genuine article, the team aims to quantify the mechanical interactions between the human tongue and certain foods.

“Recreating the surface of an average human tongue comes with unique architectural challenges,” said the study’s lead author Dr Efren Andablo-Reyes. “We aimed to replicate the mechanically relevant characteristics of the human tongue, in a surface that is easy to use in the lab to replicate oral processing conditions.”

The mysteries of the human tongue

As with all mammals, human tongues have a highly-sophisticated topology, and it’s only when this is combined with optimal wettability, that we’re capable of critical activities like eating, speaking and tasting. In sheerly mechanical terms, these basic functions are governed by a number of bud-like asperities featured on the tongue’s lower dorsal section called papillae.

Understanding exactly how these tiny structures affect the tongue’s texture-sensing capabilities, is valuable information that could be used to make more palatable foods or medicines. At present, automated taste-testing for oral optimization involves bulk rheological evaluations, but these aren’t capable of mimicking the surfaces or lubrication of a real tongue.

As a result, human tasters are often employed within food development processes, which makes them a costly, time-intensive and ultimately subjective endeavour. For the researchers, the only way to gain a definitive understanding of how fluids interact within the human mouth, was to create a biomimetic tongue, and analyse its tribological performance.

The researchers’ 3D printed oral organ

In order to create their additive tongues accurately, the researchers obtained 3D scans of 15 healthy adults, including the dimensions, density, distribution and roughness of their oral papillae. Based on these images, the team used a Poisson point process-based randomized model to design a ‘master mold,’ with optimized spatial distribution between the papillae.

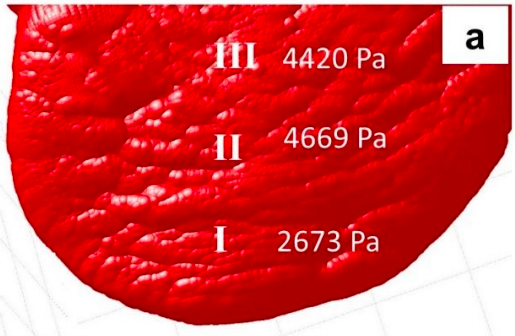

Two specific types of the miniature buds appeared most frequently within the scans: the white filiform and red fungiform papillae, leading the scientists to prioritize their inclusion in their fabricated oral device.

“We focused our attention on the anterior dorsal section of the tongue where some of these papillae contain taste receptors, while many of them lack such receptors,” explained Dr Reyes. “Both play a critical role in providing the right mechanical friction to aid food processing in the mouth with the adequate amount of saliva.”

To achieve the necessary resolution to recreate their master mold, the researchers deployed an Envision Perfactory P3 Digital Light Processing (DLP) system to 3D print sensors into a soft silicon elastomer. Varying amounts of the polysorbate 80 chemical were then added to the tongue-like devices, to provide suitable wettability, before they underwent various characterization tests.

Although some of the additive tongues showed different levels of wettability, their features proved to be identical to those of the mold, and by extension, those of the test subjects. To evaluate the deformability of their fabricated oral organ, the researchers later compared it to that of a pig, and it proved to be almost an exact match in terms of strength, wettability and texture.

Following a string of successful tests, the team concluded that their 3D printed silicone-based device could accurately emulate the topology of the human tongue. In future, the scientists believe that their replica dorsum could be used as a means of food or drug testing, as well as developing a broader understanding of how the organ functions.

“This biomimetic tongue surface could serve as a unique mechanical tool to help detect counterfeit in food and high-valued beverages based on textural attributes,” concluded study co-author Anwesha Sarkar. “Ultimately, our hope is that the surface we have designed, can be important in understanding how the biomechanics of the tongue underpin human feeding and speech.”

Previous lifelike additive innovations

Although 3D printing fully-sized transplantable human organs isn’t currently feasible, recent advances in additive technology have yielded a number of realistic replicas.

GeorgiaTECH student Alexis Noel for instance, has managed to 3D print replica papillae spines of a cat’s tongue, and used it to attract and ‘clean-up’ particles. Although the structure was 400 times bigger than a typical cat tongue, it shared the same elastic qualities.

Elsewhere, the India-based Sawai Man Singh (SMS) Hospital has begun treating oral cancer patients using 3D printing technology. During surgery, many of the patients there need to have part of their face or jawbone removed, and their doctors are experimenting with using fabricated implants as a potential treatment.

On a different note, researchers from Cornell University, have 3D printed a ‘finger-like’ soft robotic muscle, that’s capable of controlling its temperature through perspiration. The bio-inspired device’s actuators were printed using hydrogel-based composite resins, and this allowed them to retain the water needed to ‘sweat.’

The researchers’ findings are detailed in their paper titled “3D Biomimetic Tongue-Emulating Surfaces for Tribological Applications.” The study was co-authored by Efren Andablo-Reyes, Michael Bryant, Anne Neville, Paul Hyde, Rik Sarkar, Mathew Francis and Anwesha Sarkar.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a new podcast? Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the researchers’ 3D printed biomimetic tongue. Photo via the University of Leeds.