Scientists from the UK’s Animal Health Trust (AHT) and the University of East Anglia (UEA) are using 3D printed scaffolds to support bone regeneration in horses.

According to the study published in the journal Tissue Engineering, “Horses, like humans, can experience bone fractures and due to their large size and need to bear weight on all limbs during the recovery period, they can be difficult to treat.”

Using BendLay Polycarbonate filament, 3D printed scaffolds were produced that can turn induced Pluripotent Stem Cells (iPSC), derived from skin or blood cells, into osteoblasts – bone forming cells. Dr. Debbie Guest, Head of Stem Cell Research, AHT, said:

“This work paves the way towards the laboratory production of bone constructs that could be used to aid fracture repair in horses; so could ultimately benefit many horses in the future.”

As strong as a horse

According to the researchers, “Surgical techniques to improve fracture repair are improving, but to date, regenerative medicine technologies to aid fracture healing are not commonly applied in horses.” As a transparent, cost-effective solution, 3D printed scaffolds were used to enable successful, in vitro osteoblast, demonstrating the feasibility of generating 3D bone constructs through cell seeding.

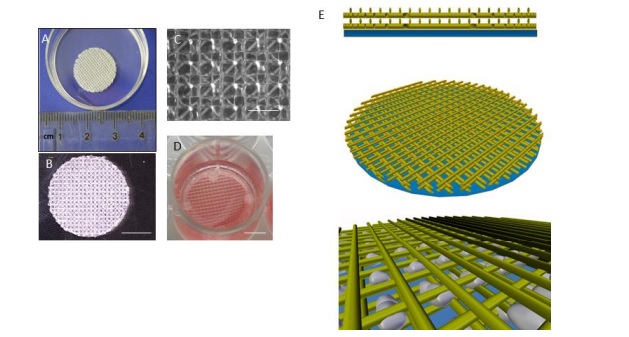

Using the MakerBot Replicator 2 3D Printer, two scaffolds were produced with fine mesh (150 µm pore size) and then cultured with cells. However, prior to cell seeding, the constructs were sterilized under UV light and went through a surface treatment. The team found that the fine mesh layer of the scaffolds retained the cells effectively.

This allowed for the diffusion of nutrients and cellular proliferation, migration, and communication. The researcher stated, “We demonstrated that a combination of 150 µm and 400 µm provided an effective scaffold for in vitro differentiation and analysis.”

“Equine iPSCs can be successfully differentiated into bone-forming osteoblasts on a thermoplastic, 3D printed polymer which forms the development of novel methods for improving fracture repair in horses in the future.”

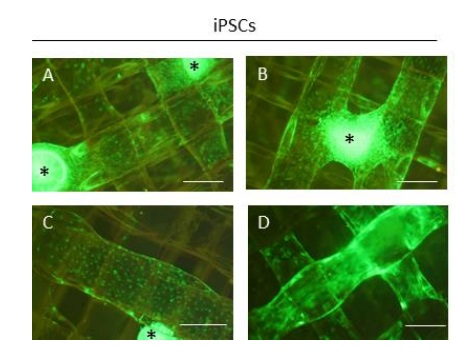

scaffold. The four images of the iPSCs are

provided to demonstrate the heterogeneity in their distribution. Image via AHT/UEA.

3D printing and animal care

Elsewhere, researchers are exploring additive manufacturing to heal larger animals. Last year, scientists and surgeons at NYU School of Medicine and NYU College of Dentistry, published a study detailing 3D printed implants that dissolve as a bone heals. The patent-pending 3D printed scaffolds are being implanted in larger animals.

“Biocompatible 3D printed thermoplastic scaffold for osteoblast differentiation of equine iPS cells” is co-authored by Arabella Baird, Noelia Dominguez Falcon, Aram Saeeda, and Deborah Jane Guest.

For more additive manufacturing research news subscribe to our 3D printing newsletter and join us on Facebook and Twitter.

We also have jobs in the industry, visit 3D Printing Jobs to learn more.

Featured image shows wild horses. Photo via Shutterstock.