Space is the ultimate test of survival. With few resources beyond Moon dust and regolith, astronauts must prepare all the necessary kit for month long expeditions ahead of time, and recycle as much waste as possible.

One well known fact of recycling aboard the International Space Station (ISS) is that there is a system that turns urine into drinkable water. The bacteria leftover from the process though can also be of use, and its not as grizzly as it might seem.

Scientists at the Clemson University, South Carolina are studying a type of yeast that feeds on the urea content in urine to see if it can be tuned to produce molecules of plastic. These molecules then, you guessed it, can theoretically be turned into filament, and 3D printed into a new object.

On a similar principle to Clemson University’s research, a team competing for a prize at the International Genetically Engineered Machine (iGEM) Foundation’s 2017 Giant Jamboree have been studying the plastic producing potential of human faeces.

Astronomical adaptation

The only criteria of the iGEM brief was to synthetically engineer bacteria to do something useful. Relating this challenge to the unforgiving environment of space, the University of Calgary’s team started to consider ways to help astronauts on lengthy missions to Mars.

Alina Kunitskaya, a chemical engineering student at UCalgary’s Schulich School of Engineering, explains, “With space travel, such as a three-year mission to Mars, there are major challenges to overcome,”

“Transporting material is difficult and expensive, and how do you anticipate every challenge and everything you need over three years on a trip to Mars?”

The powers of E. coli

After considering this question and consulting retired astronaut Colonel Chris Hadfield about their project, the team hit on the potential uses of E.coli bacteria. As one of the most widely documented and well understood bacterial microbes, E.coli presented a lot of versatility to the team. It has been used in bioplastic research at TU Delft, to make MIT’s bioactive running suit, and in field technology development at the U.S. Army Research Laboratory (ARL).

Making bio polyester

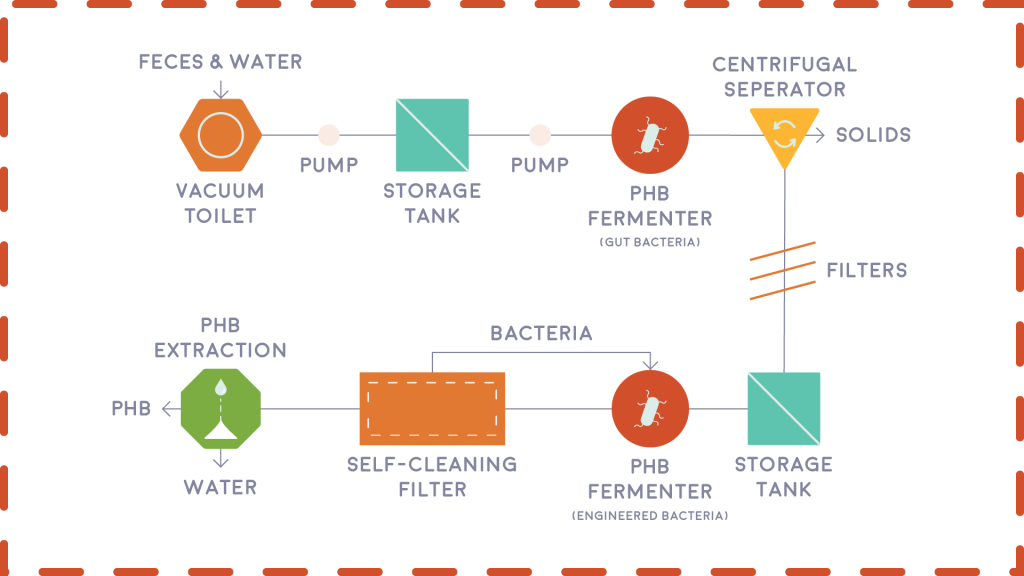

UCalagary researchers use E. coli extracted from solid human waste to produce Poly(3-hydroxybutyrate) (PHB) – a polyester and bioplastic. After a lengthy fermentation and filtering process, PHB can be extracted from E. coli using compressed air pumped in from the Martian atmosphere.

The resulting product is a powdered form of PHB that can either be turned into a filament using hot extrusion process, or potentially sintered, using a variety of space-safe methods currently under research.

Medal winning research

The UCalgary team won a gold medal for their project, Astroplastic: From Colon to Colony, the theory of which is well document on the supporting wiki site. The researchers also proved the concept by 3D printing a wrench using E. coli produced PHB.

Read more of the latest 3D printing research, by subscribing to the 3D Printing Industry newsletter, following us on Twitter, and liking us on Facebook.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections for best research team and more here.

Featured image shows the Astroplastic From Colony to Colon cover page. Image via 2017.igem.org/Team:Calgary/Team