A collaboration between the Massachusetts Institute of Technology (MIT), the National University of Singapore and New Balance Athletics has developed a self-cooling running suit and shoes with the use of 3D printing.

The sportswear items harness bacteria microbes to create a material that effectively self-cools “in synergy with the body.”

Making of a living garment

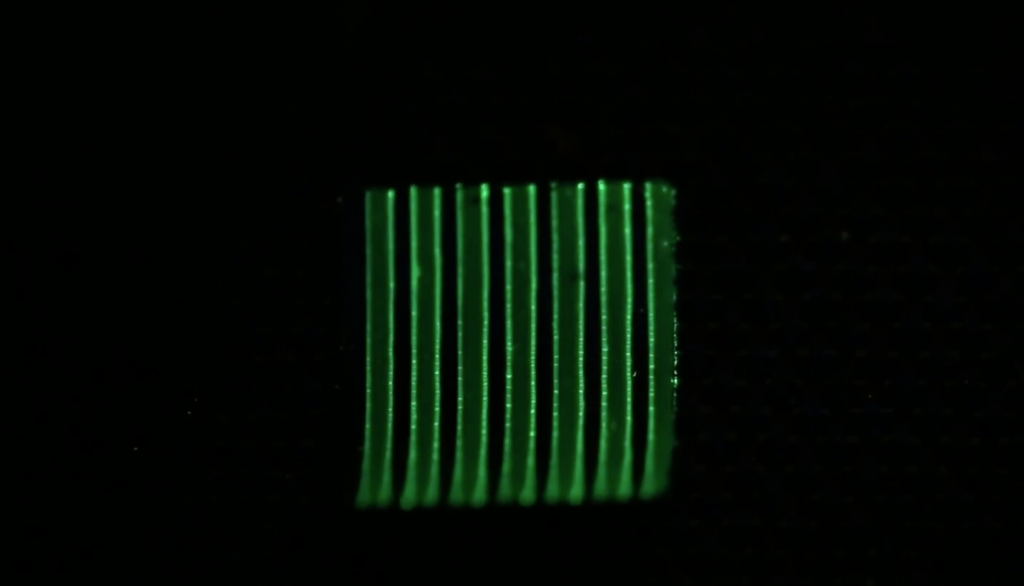

In this particular study, researchers draw on the hygroscopic, meaning “ability to absorb moisture from the air”, and biofluorescent, “glowing under UV light”, qualities of bacteria to create air-release flaps and visibility.

The base material for both items is latex. To start, E. Coli bacterium microbes are introduced to the materials using a micro 3D printing technique based upon liquid deposition.

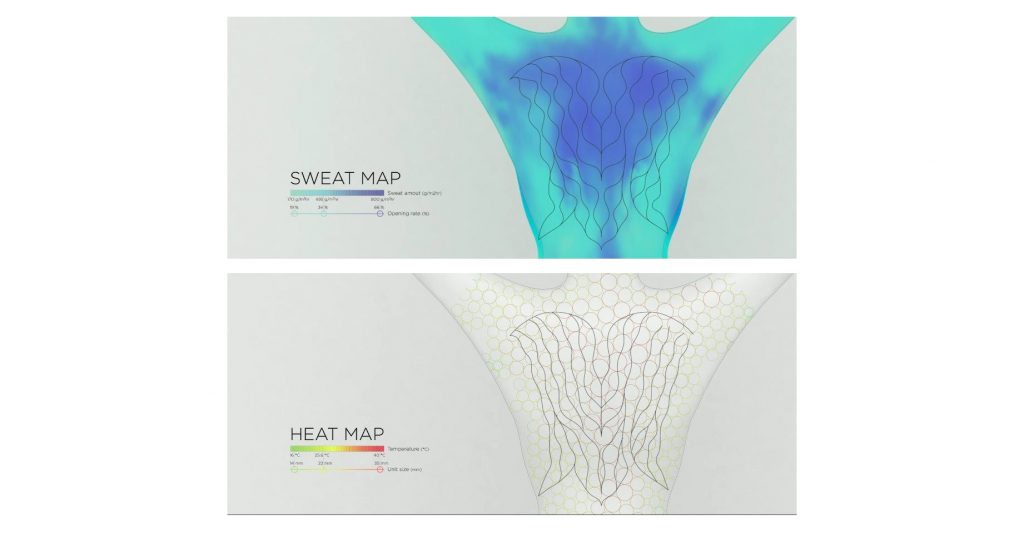

When dry, E. Coli cells naturally contract causing the latex to bend. And when humidity is introduced, the cells absorb moisture from the air and become flat.

To tailor these actions to suit the opening and closing of flaps, the researchers coated the bacteria on each side of the fabric. This means that when dry, the natural “bending” force is matched by the same force from the other side, putting the fabric flaps in a neutrally closed state.

As humidity increases, single cells swell and shrink depending upon exposure to moisture. This causes an imbalance in the structure, where the moistened cells give way to the dryer cells on the opposite side, yielding a bend and opening the cooling flap.

The level of flexibility in this yield is enhanced by subsequent layers of material. TPU is used for bonding the layers, mesh fabric is used to create air pockets between the skin and the suit, and a stretchy fabric is used in the core and back panel.

When humid, the bacteria also exhibits bioluminescent properties, meaning the runner can be easily seen in the dark.

Improvements and biofabric possibilities

Future work will focus on stability of the cells to ensure the effectively living garments are sustainable over a substantial period of time. Preliminary wash tests (100 dry-wet cycles) have shown positive results to the continued flexibility of the garments, but further work can be done to embed the bacteria within the fabric itself.

Harnessing the hygroscopic and biofluorescent behaviors of genetically tractable microbial cells to design biohybrid wearables from MIT, the National University of Singapore and New Balance Athletics, is available to read online in the journal of Science Advances.

The paper is co-authored by Wen Wang, Lining Yao, Chin-Yi Cheng, Teng Zhang, Hiroshi Atsumi, Luda Wang, Guanyun Wang, Oksana Anilionyte, Helene Steiner, Jifei Ou, Kang Zhou, Chris Wawrousek, Katherine Petrecca, Angela M. Belcher, Rohit Karnik, Xuanhe Zhao, Daniel I. C. Wang and Hiroshi Ishii.

Bacteria – the magic ingredient

As a highly versatile and well documented bacterium, E. Coli is frequently the subject of smart-tech research. Strains of the microbe were used by MIT researcher Neri Oxman to create the color in the 3D printed Vespers masks for Stratasys. The US Army Research Laboratory (ARL), also in collaboration with MIT, are looking into E. Coli’s use to make smart wearable tech for soldiers, and researchers at TU Delft in the Netherlands have developed an inexpensive method for 3D printing strains as a material.

Luminous proteins have also been used by researchers at Friedrich-Alexander University Erlangen-Nürnberg (FAU) in Germany in the development of flexible LED screens.

For more of the latest 3D printing related research sign up to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

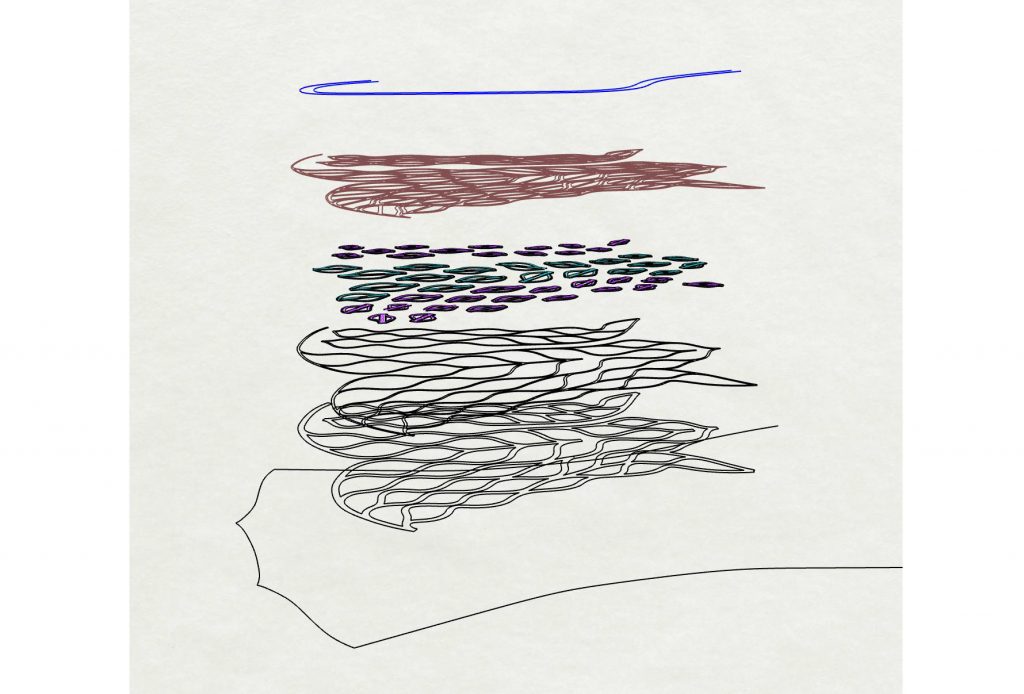

Featured image: Design of the running suit with 3D printed active bacteria for cooling. Image via Science Advances (Supplementary Materials)