Twenty one industrial and research partners from eight European countries will be coming together to undergo the MULTI-FUN project – a three year initiative aimed at advancing multi-material metal additive manufacturing.

The project was funded by the EU’s Horizon 2020 innovation program and comprises two parts: the first will involve improving the performance and efficiency of 2020’s metal AM systems while the second will be focused on enabling the multi-material fabrication of complex 3D models without sacrificing large part size capabilities.

An ambitious project

The work, at its core, will see the completion of four science and technology objectives related to multi-functional and multi-material 3D printing. This is not specific to any one AM technology, as the project aims to advance the sector as a whole. Some of the partners will be working on the PBF process while some may be working on WAAM. A few of the partners will even be working on developing novel materials specifically for multi-material printing.

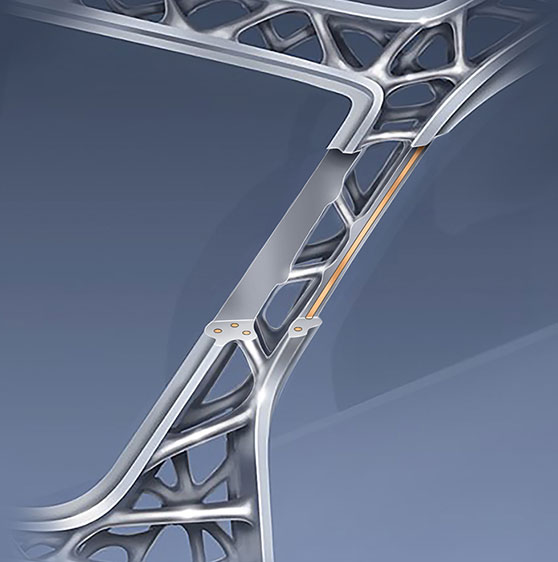

By the end of it, the consortium hopes its work will enable the printing of a number of previously impossible objects including multi-material heat sinks with high thermal conductivity and complex metal parts with embedded electronics. The partners also hope to be able to integrate and print tailored optical fibers for structural health monitoring purposes.

The four objectives

The first objective entails the development of five new materials specifically for AM, three of which will use nanotechnology. These materials will feature a number of impressive thermal, electrical, and wear resistance properties to enable the creation of new multi-functional products.

The second objective looks to develop an entirely new system, complete with hardware and software, to integrate several AM technologies into one. This way, the five new materials can all be printed using different fabrication techniques. In total, the partners hope to end up with at least ten new multi-material combinations printed with different metal AM technologies working in harmony.

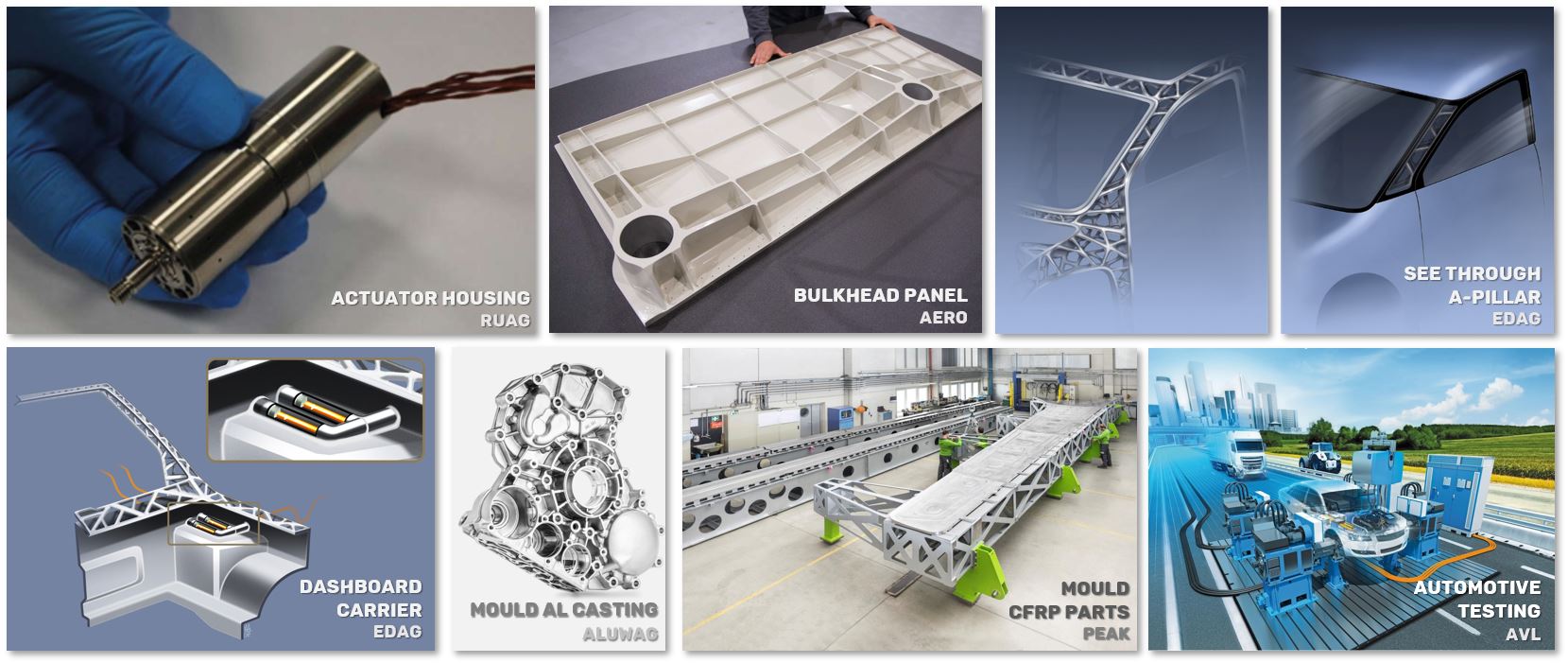

The third objective will see the printing and evaluation of seven physical demonstrators of the newly developed multi-material printing system. These demonstrators will be for three use cases (structural parts, molds, and test equipment) and will cover four markets (automotive, aviation, aerospace, and manufacturing).

The fourth and final objective is to go back and iterate over the materials, hardware, and demonstrator designs to assess and improve the environmental and economic impacts of the project. As a result, the partners expect to develop a set of new standards for multi-material metal 3D printing and support regulatory bodies in adapting to the new technology.

A full list of the partners and their contributions can be found here.

Multi-material 3D printing has been attempted before, but it’s still very much in its infancy. Earlier this year, Belgium-based Aerosint developed a special dual-powder recoater and deployed it in a laser PBF 3D printer made by Aconity3D. The recoater utilizes two rotating patterning drums that each selectively deposit a separate powder onto the powder bed.

Elsewhere, Harvard University researchers developed a new method of multi-material 3D printing called MM3D. The novel technique utilizes a printhead with eight different material channels and only one nozzle. The material being deposited can be switched up to 50 times a second, enabling faster print times with crisp material interfaces in a single part.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows multi-material metal part. Image via MULTI-FUN.