The specialist recoater developed by Belgium-based Aerosint will be deployed in a new 3D printer made by Aconity3D, capable of laying dual-powder layers for laser powder bed fusion systems. The Formnext Startup challenge winner previously announced its partnership with German metal processing specialist, Aconity3D. A new joint sales agreement between the two companies has now been initiated whereby the recoater will be an optional add-on to the Aconity MIDI+.

The Aerosint recoater

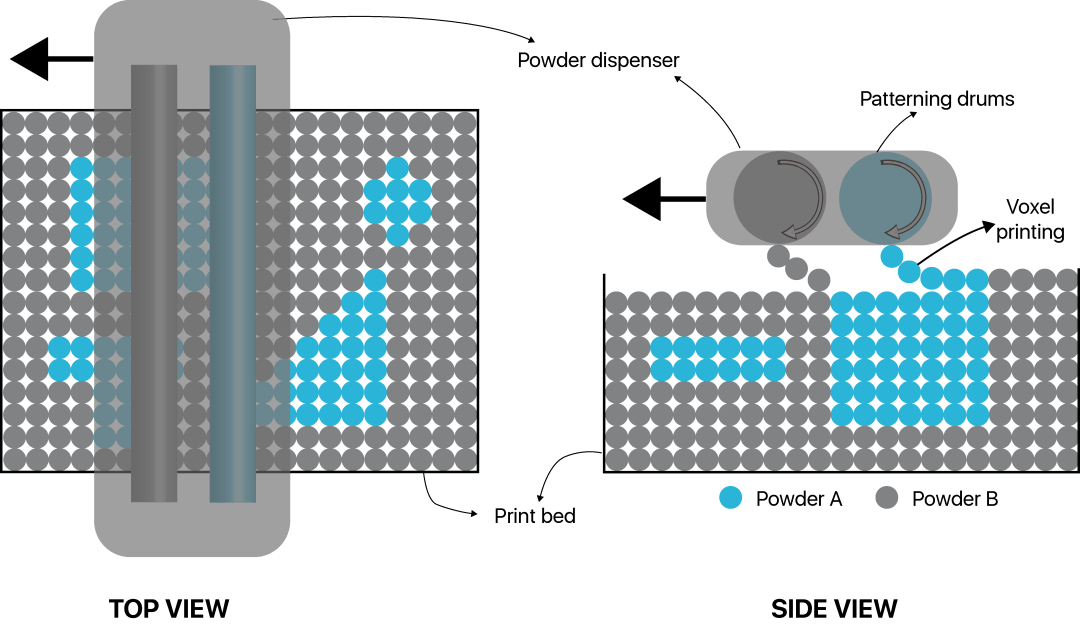

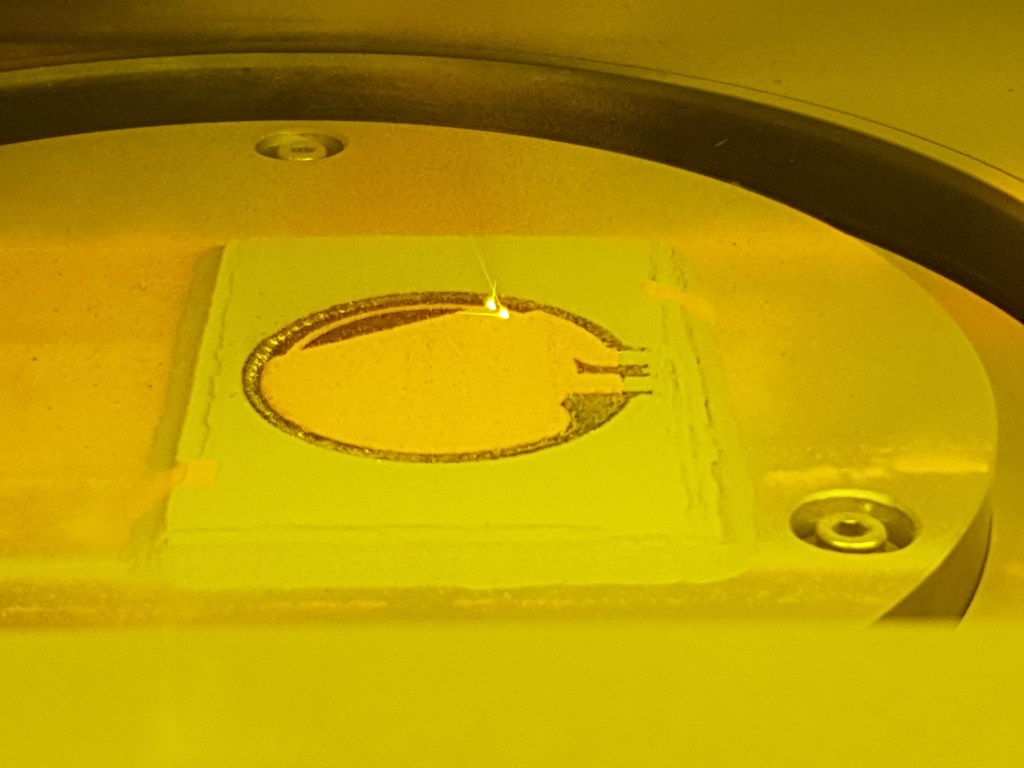

The recoater, like any other, relies on the deposition of dry powder particles. A chosen powder is guided onto a rotating patterning drum. The powder, upon reaching the bottom of the rotating patterning drum, leaves the drum selectively and is deposited on the powder bed. One patterning drum is required per powder type and the current iteration of the recoater houses two drums. This allows for two powders to be deposited on the powder bed at the same time.

Speaking with 3D Printing Industry Edouard Moens de Hase, Co-Founder and Managing Director at Aerosint, explained: “We can pattern with two powders simultaneously and as such create dual powder images. In the future we could scale this up to more powders. Our technology works with standard 3D printing powders: metals, ceramics, polymers.”

Applications and challenges

The Aerosint team believes the dual powder recoating capabilities of the system will have disruptive effects in a range of applications from heat exchangers to wear-resistant cutting tools and even rocket nozzles.

The Aerosint MD adds, “There are plenty of other applications that are still to be uncovered now that the technology works. We get much interest from industrials who not always share why they need multi-material but the market interest is clearly present. I’ve noticed a clear difference compared to a year ago. Multi-material has made its entrance into people’s minds.”

One challenge the co-founder touched on was the separation of the powders once mixed and reclaimed. Methods of powder separation do currently exist, often relying on differences in material properties like density and magnetism, but he agreed that it is still ideal to avoid mixing the powders altogether. The team has considered adding a third cheap, reusable material into the mix to act as a filler. The addition of the filler would allow users to only deposit the necessary quantity of expensive powders into the powder bed, saving on material separation costs.

Multi-material 3D printing is an area of additive manufacturing that has garnered much attention in recent years. Researchers at Harvard University have developed a new method of multi-material 3D printing, whereby a printhead containing multiple channels delivers up to eight different materials through a single nozzle. Elsewhere, in Zürich, scientists have developed a novel 3D printing method capable of manufacturing multi-metal microstructures with a resolution of 250 nanometers at 10 voxels per second. What sets Aerosint apart, however, is the multi-material printing of different forms of metal, ceramic and plastic powders, allowing for a much greater number of combinations and consequently, potential applications.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

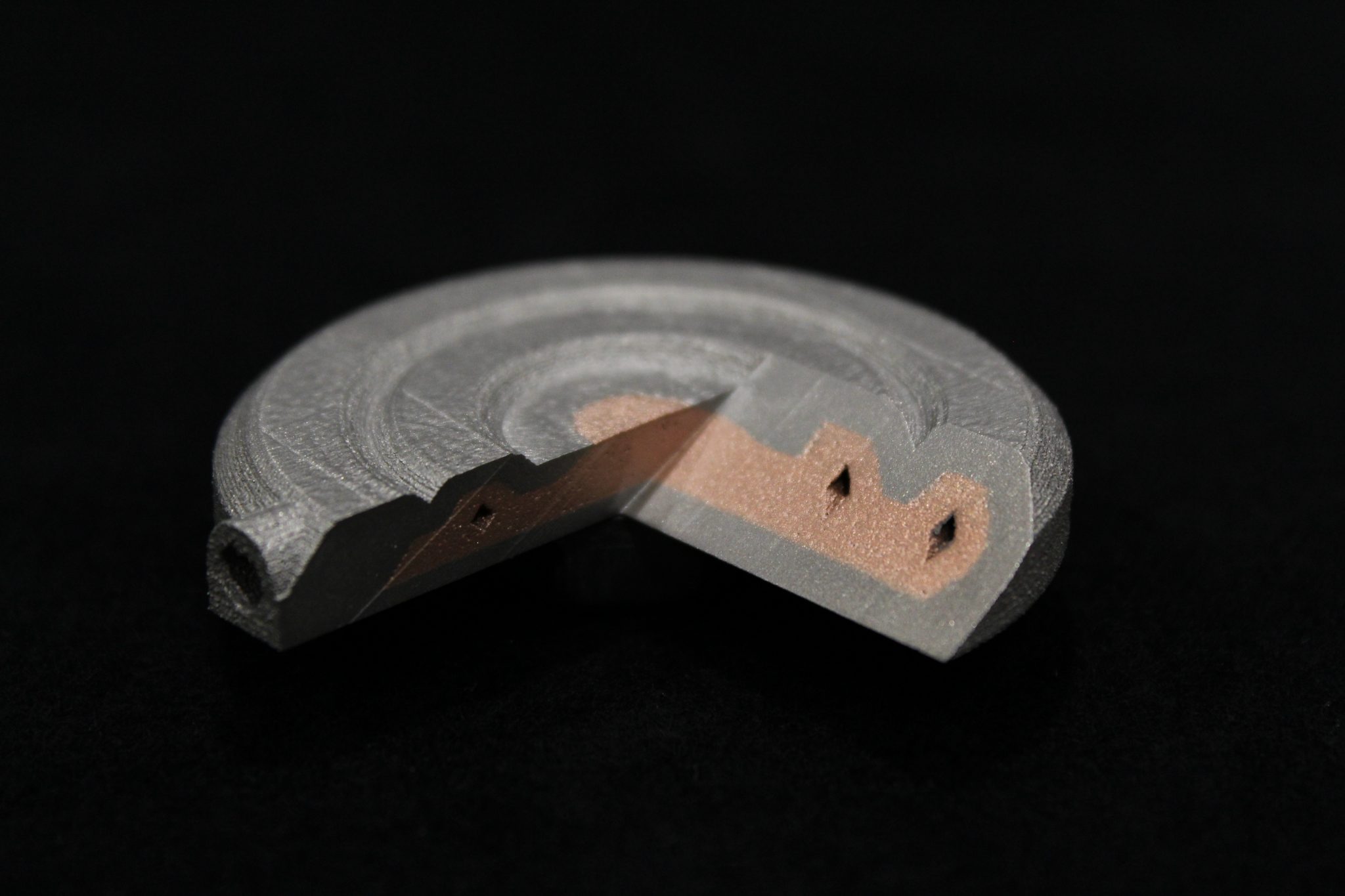

Featured image shows dual metal part created using Aerosint’s recoater. Photo via Aerosint.