3D printed foot models fabricated on a Tractus3D 3D printer have helped wound dressing specialist Pedilay Care to demonstrate the use of its novel foot bandages.

Pedilay’s foot bandages are used primarily in the treatment of diabetic foot syndrome, with the firm relying on foot models to test and demonstrate their products. Having failed to find models suitable for their needs, the firm turned to Tractus3D and its reseller phoenix GmbH to address the drawbacks of traditional custom-made models, which are often expensive, weighty, inaccurately shaped, or have inadequate surfaces.

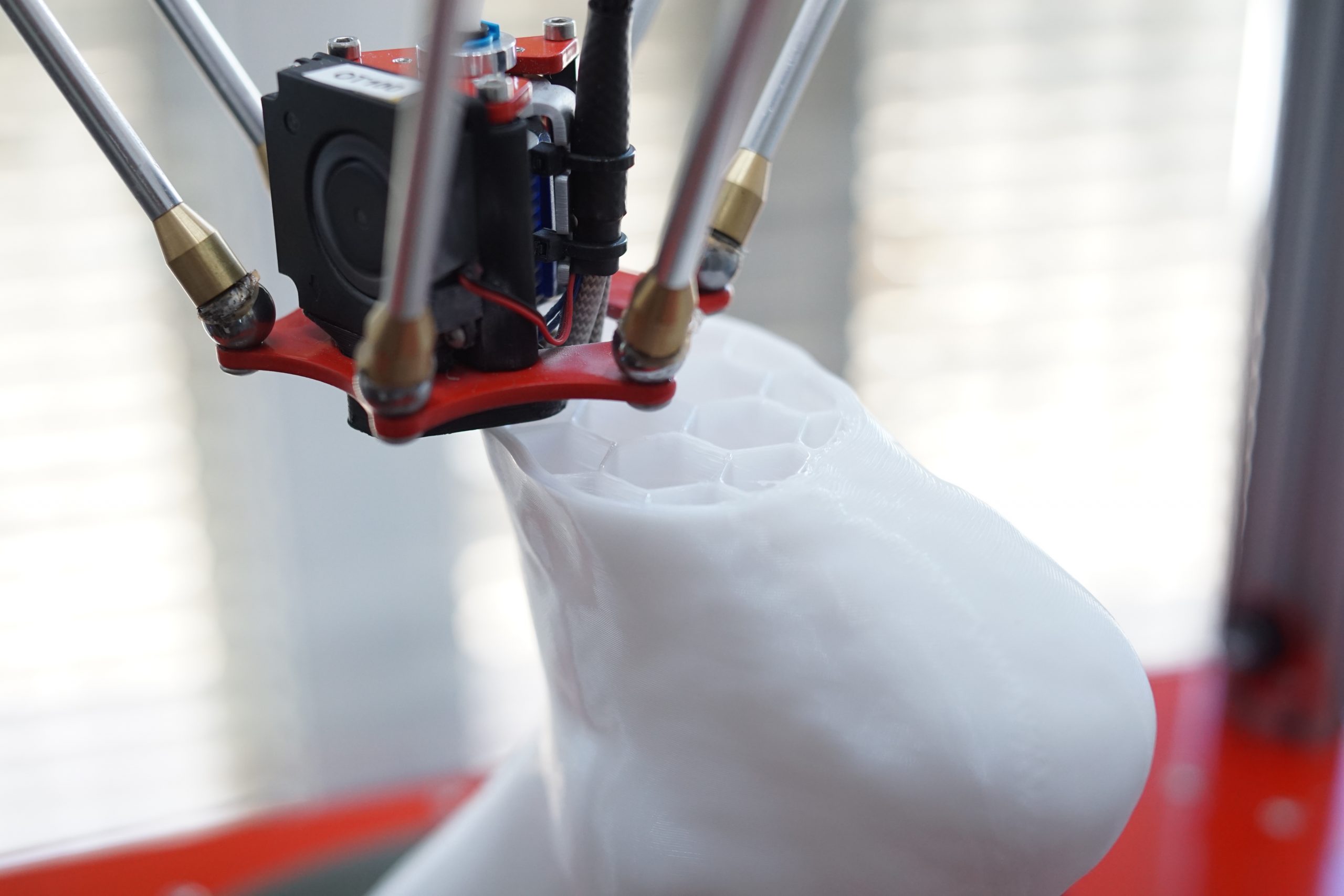

During the project, phoenix worked with Pedilay to design and produce two complete individualized leg models for the firm using 3D scanning and Tractus3D’s T850 FFF 3D printer.

3D printing anatomical models

Tractus3D specializes in delta FFF systems and has a portfolio of 3D printers spanning low-cost desktop systems, large-format multi-meter machines, and high-temperature professional 3D printers. The second industrial 3D printer in the firm’s DESK series, the T850 enables users to print objects up to 340mm in height and 280mm in diameter. The machine is capable of printing plastic objects in multiple materials including PLA, PETG and ABS for applications in a variety of industries.

Due to its prototyping prowess, one application the printer is particularly suited for is the production of anatomical models for the healthcare sector. 3D printing is being increasingly leveraged to produce such models as it can provide greater customization opportunities, shorter lead times, and lower costs, among other benefits.

For instance, patient-specific 3D printed anatomical models that can be utilized by doctors to enhance diagnoses, clarify treatment decisions and plans, and also practice surgical interventions in advance of the real thing.

Having found traditional foot models to be limited in size, form, and featuring undesirable anatomical positions, Pedilay turned its attention to 3D printing to produce custom-made models suitable for displaying its bandages.

Tractus3D’s reseller, phoenix, was tasked with scanning, designing, and printing two models that could cover typical fitting scenarios while demonstrating the size range that Pedilay’s bandages cater for.

Producing the custom foot models

To begin, phoenix used a high-resolution 3D scanner to digitize two of Pedilay’s existing foot models, capturing detailed areas such as toe spacing and wrinkles around the heel. The data from the scans was then uploaded into 3D modeling software, where the digital models were adapted in line with Pedilay’s requests. These changes included correcting the leg axes, lengthening the foot shaft, and flattening the arch of the foot.

Once the team was happy with the digital design, the models were then 3D printed on Tractus3D’s T850 system. The 3D printed parts could then be joined together and mounted to create a customized, full leg model capable of optimally displaying Pedilay’s wound dressings.

According to Tractus3D, the 3D printed parts were quickly available and able to be reproduced at the click of a button, while the tool-less nature of the technology meant the models could be fabricated cost-effectively from the very first production run.

Pedilay is now able to effectively demonstrate the use of its bandages using the 3D printed models, in addition to discussing and testing new product ideas and improvements to its wound dressings.

Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows foot models 3D printed on the Tractus3D T850 help Pedilay to display its foot bandages. Photo via Tractus3D.