At the 2019 Paris Air Show, award-winning OEM GE Additive has announced that TUSAŞ Engine Industries, Inc. (TEI), an aircraft engine part manufacturer based in Turkey, has invested in four of its Direct Metal Laser Melting (DMLM) additive manufacturing machines. Specifically, TEI has purchased two of GE Additive’s M LINE Factory systems, and two M2 cusing machines.

TEI, which was founded by GE Additive sister company GE Aviation, acquired the 3D printers from GE Additive as part of a continued investment in additive manufacturing. The company aims to become an expert in additive manufacturing for the Turkish aviation industry. Professor Dr. Mahmut Faruk Akşit, President & CEO, TEI, comments:

“Today, we invest in TEI’s future by investing in additive manufacturing, ‘the future of manufacturing.’ Our longstanding partnership and collaboration with GE is now broadening with GE Additive’s machine portfolio.”

Supplying the Turkish aviation industry with additive manufacturing

As well as GE Aviation, TEI was also founded by Turkish Aerospace Industries, the Turkish Armed Forces Foundation and the Turkish Aeronautical Association as part of a joint venture in 1985. The company focuses on manufacturing parts for the global and Turkish aviation industry. It has produced over 1,000 different parts for a variety of aerospace products over the past thirty years.

TEI’s new GE Additive M LINE Factory and M2 systems are planned to be installed at its headquarters in Eskişehir, northwestern Turkey. They join the company’s current roster of laser and Arcam EBM machines, expanding TEI’s overall additive capabilities.

“The M2 remains the machine of choice for our aerospace customers – and for good reason,” explained Jason Oliver, President & CEO, GE Additive.

“It’s not only the work horse of our machine portfolio, but it meets the specific needs and demands of this highly-regulated industry.”

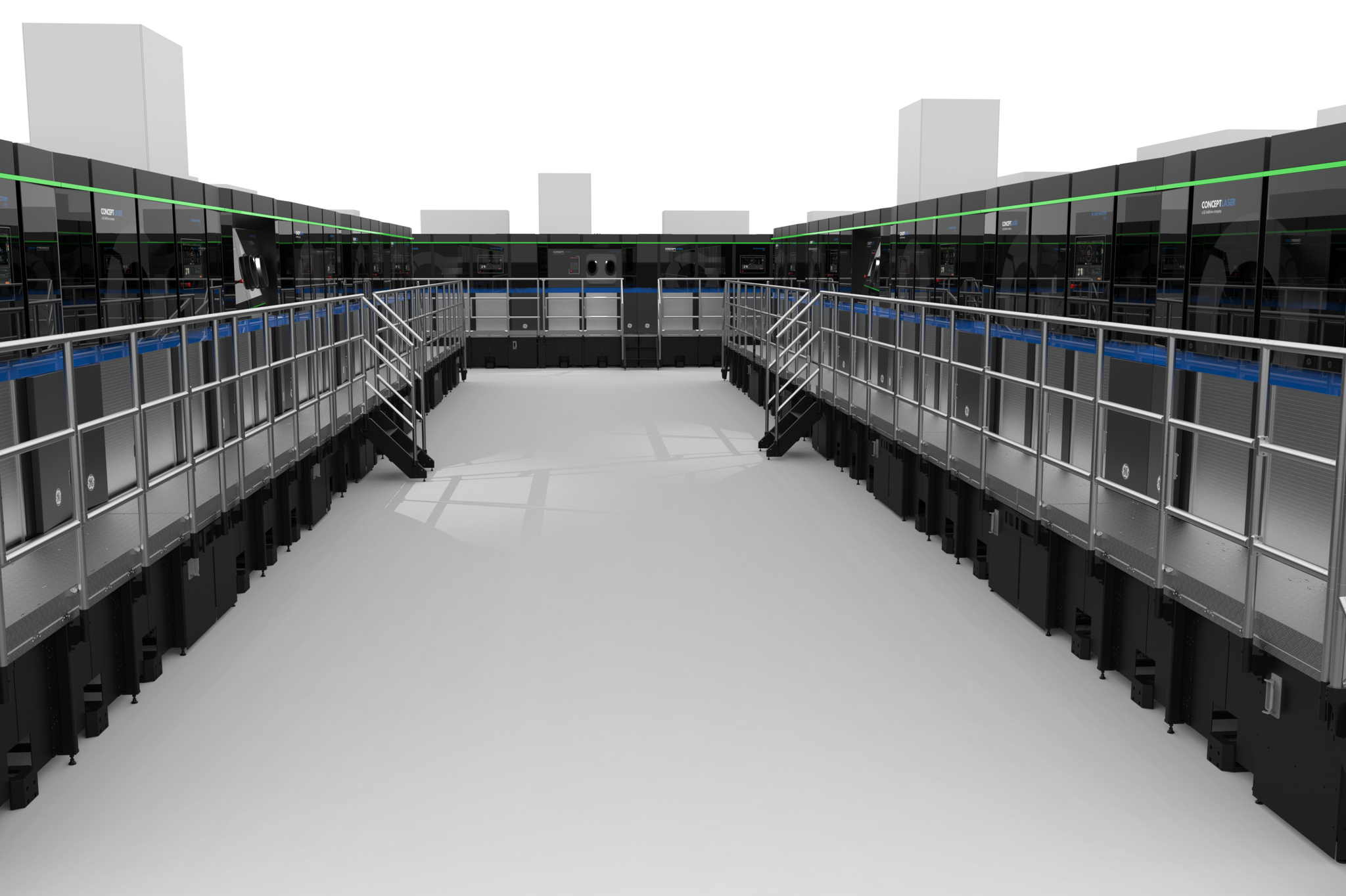

The M2 Cusing and M LINE Factory systems are developed by Concept Laser, a German metal 3D printing manufacturer, which was acquired by GE Additive in 2016. Since then the M LINE Factory has undergone software and hardware revisions, becoming commercially available this year.

Oliver added, “And with so many aerospace customers on the cusp of industrialization, our M LINE Factory with its modular machine architecture, outstanding automation and reliability makes it the perfect solution to drive economical, scalable series production on an industrial scale.”

Shifting towards industrial additive manufacturing in aerospace

Updating its manufacturing methods to today’s standards, TEI’s continued investment in additive manufacturing technology and infrastructure over the years falls in line with the production patterns of the aerospace and defense industry. These industries have demonstrated a continued shift from prototyping to serial, industrial-scale production for additive manufacturing.

Most recently Oerlikon AM, the additive manufacturing branch of Swiss technology group Oerlikon has entered into a part supply partnership with Augsburg-based MT Aerospace to accelerate the adoption of metal 3D printing in the aerospace industry. In an interview with 3D Printing Industry, Dr. Christian Haecker, Head of Additive Manufacturing Industrialization at Oerlikon, stated that:

“The medical sector is a leading and mature user of the technology. This is because biocompatibility, customization, complex lattice shapes are required and there is more acceptance of current AM costs [and] Aerospace and Defense are now following.”

Other announcements from the Paris Airshow this week have included the development of the partnership between Stratasys and Boom Supersonic, Collins Aerospace Systems’ plan to open an additive manufacturing innovation hub in Singapore and Norsk Titanium RPD technology becoming part of the Boeing Material Allowables Program.

For the duration of Paris Le Bourget this week, GE Additive will be exhibiting in Chalet 132. TEI is exhibiting in Hall 4 stand D178.

For more additive manufacturing updates from the 2019 International Pairs Air Show and other news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Visit 3D Printing Jobs to make your next career move.

Featured image shows GE Additive and TEI signing ceremony at Paris Air Show 2019. Photo via GE Additive.