GE Additive has formed software partnerships with industry leaders and has announced the release date of the M LINE FACTORY system.

In 2016, GE Additive acquired a 75% stake in Concept Laser, a German metal 3D printing manufacturer and maker of the M LINE FACTORY system. Since then the M LINE FACTORY has undergone software and hardware revisions. Now GE Additive has announced that the M Line Factory will be commercially available in 2019.

Jason Oliver, President and CEO of GE Additive, said, “The positive impact the M LINE FACTORY can have on our customers’ operations and their bottom line is huge. It’s important we provide technologically advanced systems that are reliable and add value to our customers. M LINE FACTORY delivers on those commitments.”

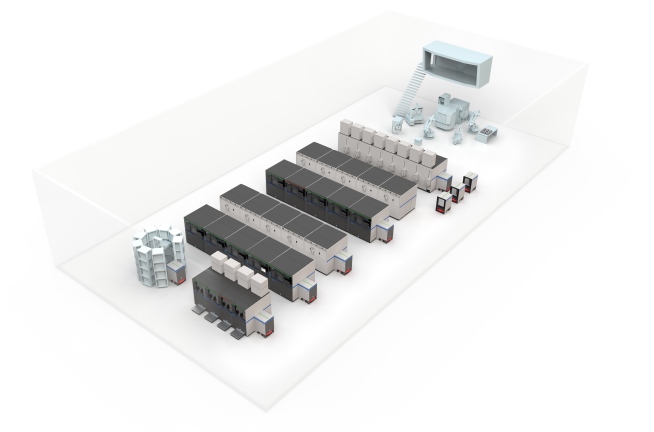

M Line 3D printing factory of the future

The M Line Factory system is designed to be an industrial scale automated production 3D system. It consists of a metal laser printer M LINE FACTORY LPS (Laser Processing Station) and a material handling station, M LINE FACTORY MHS, both placed side by side.

An automated vehicle loads the compatible metal powder into the 500 x 500 mm build platform of the LPS, which a uses 4x400W or 1000W fiber laser to 3D print a metal object.

The finished part is transported to the M LINE FACTORY MHS using an internal transport mechanism connecting the LPS and MHS. In the MHS, an automated sieving system removes the excess material from the 3D printed metal part. Once cleaning is finished, the metal part is unloaded into an automated vehicle to be logged. The entire process is fully automated and free of manual handling.

The automated factory is formed by stacking multiple LPS and MHS workstations alongside each other.

GE Additive software strategy

GE Additive has also announced a partnership with some of the leading 3D software companies. These include two American software makers, Autodesk and PTC, the German software company Siemens PLM software and California-based software security platform, Vera Security.

Furthermore, GE will also collaborate with the French 3D software company Dassault Systèmes, publisher of SolidWorks and maker of the on-demand manufacturing platform, 3DEXPERIENCE Marketplace.

These new partnerships are formed to make advances in additive manufacturing digital workflows. The upgrades will simplify the design to print process with better security, and improve the performance of GeonX’s simulation.

GE Additive is currently demonstrating its software system at formnext 2018. The company has stated that its software suite with enhanced security and design features will be commercially available in May 2019.

Lars Bruns, Executive Software Leader at GE Additive, said, “Feedback is a critical activity in the development of any software system, which is why we are demonstrating our current capabilities in Frankfurt. Over the next eight months, we’re seeking customer input from our users to help us inspect, adapt and iterate ahead of our commercial launch.”

GE Additive can be visited at formnext 2018, Hall 3.0, Stand D30

To know more about the factories of future subscribe to our 3D printing newsletter. Also join us on Facebook and Twitter.

For jobs in the 3D printing industry visit our 3D Printing Jobs.

Featured Image shows the fully automated M Line Factory systems. Image via Concept Laser