Carbon, a California-based 3D printer and materials manufacturer, has made three announcements, which highlights Carbon’s expansion into the American and European market.

This includes a price reduction of its resins, a global collaboration with Core 3D Centres, and an expansion of its European production network.

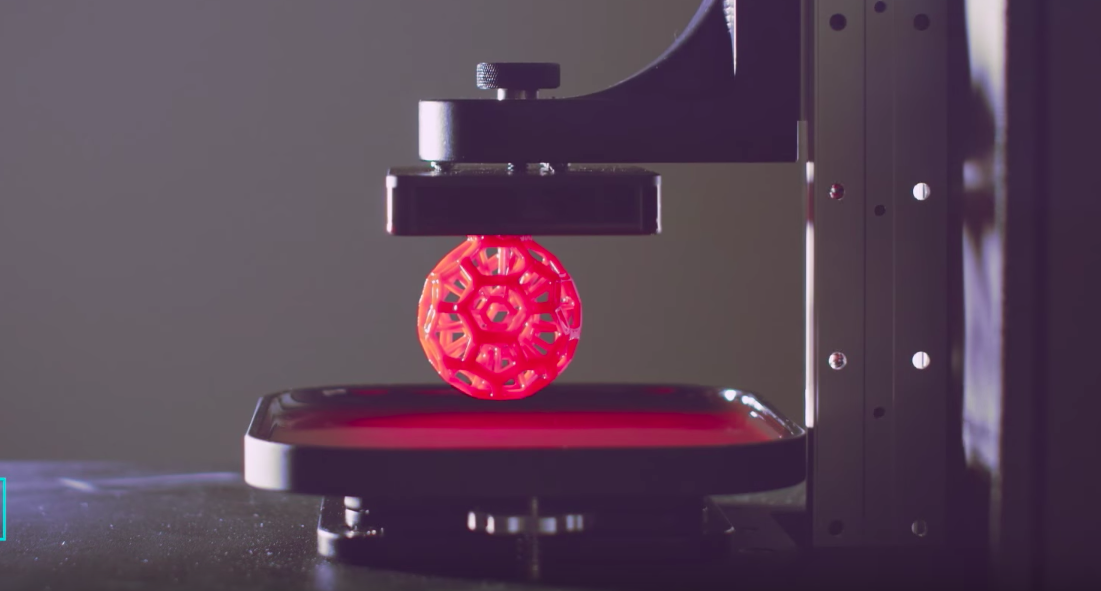

As a manufacturer in the additive manufacturing industry, Carbon emphasizes the potential of 3D printing for end-use production. The company is known for Digital Light Synthesis (DLS) printing which uses Carbon’s proprietary method known as Continuous Liquid Interface Production (CLIP). The CLIP process uses light and oxygen to produce 3D printed models from resin.

Resins at reduced costs

Carbon has announced that it has reduced the prices of its materials, effective immediately.

Carbon’s CEO and co-founder, Dr. Joseph DeSimone, explained the motivation behind this move. “The global appetite for using digital manufacturing for high-volume production is rapidly growing, as more and more manufacturers are implementing these next-gen technologies into their processes and supply chains, […] Carbon has made digital manufacturing a reality, and the skyrocketing need for large-volume production enables us to introduce the most radical reduction of resin pricing ever.”

The following 3D materials by Carbon will now be available at reduced prices:

– Elastomeric Polyurethane(EPU 41), a production-grade elastomer

– RPU 70 (Polyurethane), an ABS-like rigid flame-resistant plastic

– EPX 82 (Epoxy), an engineering material for industrial applications

“This move will also create new high-value applications and opportunities that were previously impossible, helping to transform the modest, estimated $10B 3D printing world into a multi-hundred-billion-dollar industry.”

Carbon materials will now be considerably cheaper if ordered in bulk. A delivery of 50 or more liters of EPX 82, EPU 41, or RPU 70 will cost $50 per liter. The following video from Carbon demonstrates the high resilience of EPU 41.

Carbon partners with Core3D

In recent years, 3D printing has had a significant impact on the dental market. According to SmartTech Publishing, a market research publisher on additive manufacturing, 3D printing in the dental industry has grown by 35%, in two consecutive years.

A new partnership between Carbon and Core 3D Centres, a UK-based 3D printing digital solutions provider for the dental industry, will exploit this market further.

Mark Maier, Core 3D’s Managing Director of Global, said, “The dental industry’s use of additive manufacturing has skyrocketed over the last couple of years, but it wasn’t always like that. For some time, dental labs were plagued by 3D printed parts that were inconsistent and poorly made with a limited range of materials, but that’s all changed with Carbon.”

The new alliance will provide the customers of Core 3D access to Carbon’s 3D printing systems and materials.

Recently, Carbon has been active within the dental industry. Earlier this year, Carbon’s DENTCA resin was approved by the FDA. It was also reported that Carbon released a DLS material certified for dental applications.

Maier explained this trend, “We’ve seen tremendous success deploying Carbon’s technology in the U.S. – high throughput, accuracy of prints using durable, high-quality materials, constant uptime, first-class education and customer support. We want to implement the same success in our dental labs around the world.”

Carbon expands partners network

Following its partnership with Fast Radius, Carbon has also expanded its network of partners. The company has forged a partnership with four Europe-based 3D service bureaus. The new partners include Complete Fabrications, a UK-based engineering prototype service provider, Erpro Group, a French 3D service bureau, and two German 3D services providers, Kurz and Rapid Product Manufacturing (RPM).

Dana McCallum, Carbon’s Head of Production Partnerships, said, “Digital fabrication technology has evolved from the early days of conventional 3D printing of prototyping applications to full-scale digital manufacturing systems.”

On Carbon’s business strategy, McCallum elaborated “An important part of Carbon’s strategy is to empower manufacturers around the world with the many benefits of digital fabrication. By being part of the Carbon Production Network, our partners have a truly scalable, complete digital manufacturing platform that offers a faster process and creates high-quality, end-use parts with properties similar to injection molding.”

Carbon can be visited at this week at Formnext 2018, where it is located in Hall 3.1, Stand H30.

For more news on the latest developments in the 3D printing industry, subscribe to our 3D printing newsletter. You can also follow us on Facebook and Twitter.

For jobs in 3D printing, visit our 3D Printing Jobs.

Featured image shows details of an RPU 70 oil tank. Photo via Carbon.