Italian 3D printer manufacturer WASP is collaborating with Mario Cucinella Architects (MCA), an architectural firm based in Bologna. Together the partners are 3D printing a model for a sustainable global habitat.

Named TECLA, the housing model is based on a circular manufacturing process utilizing reusable, recyclable materials taken from the local terrain. It is built using the Crane WASP construction 3D printer, and represents an attempt at establishing an “eco-housing” solution. WASP and MCA, with help from various partners, have embarked on the project in response to exponential population growth and subsequent lack of housing. Planned for construction near Bologna, Italy, the two firms received clearance for a TECLA prototype in May 2019, with 3D printing beginning in September. It is due for completion in early 2020.

“Together with WASP we aim at developing an innovative 3D-printed prototype for a habitat that responds to the increasingly urgent climate revolution and the needs of changes dictated by community needs,” explains Mario Cucinella, MCA founder.

“We need a paradigm shift in the field of architecture that gets closer to the needs of people, thus finding an answer for the ‘Earth’ within the ‘earth’. A collaboration that becomes the union between empathic architecture and the application of new technologies.”

The World’s Advanced Saving Project

Founded in 2012, WASP was established with the aim of developing viable construction processes based on the principles of circular economy. The company sees the construction of 3D printed, ‘zero-mile’ homes, using materials found on the surrounding area, as key to solving the global population crisis, which has created substantial challenges for governments related to housing solutions. Its research has therefore been focused on building a 3D printer capable of constructing clay houses in the shortest period of time, and in the most sustainable way possible.

The company’s first 3D printer was the PowerWASP, a 3D printer with milling capabilities, before it moved on to developing its DeltaWASP range of 3D printers, which covered small to large-scale 3D printing build volumes. A significant milestone for WASP in 2015 was the development of its BigDelta WASP, 12m high 3D printer for building homes, capable of extruding both technical (concrete) and raw materials, such as straw and terrain. The company used the machine to embark on its Shamballa project – an eco-friendly technological village in Italy built using resourceful additive manufacturing.

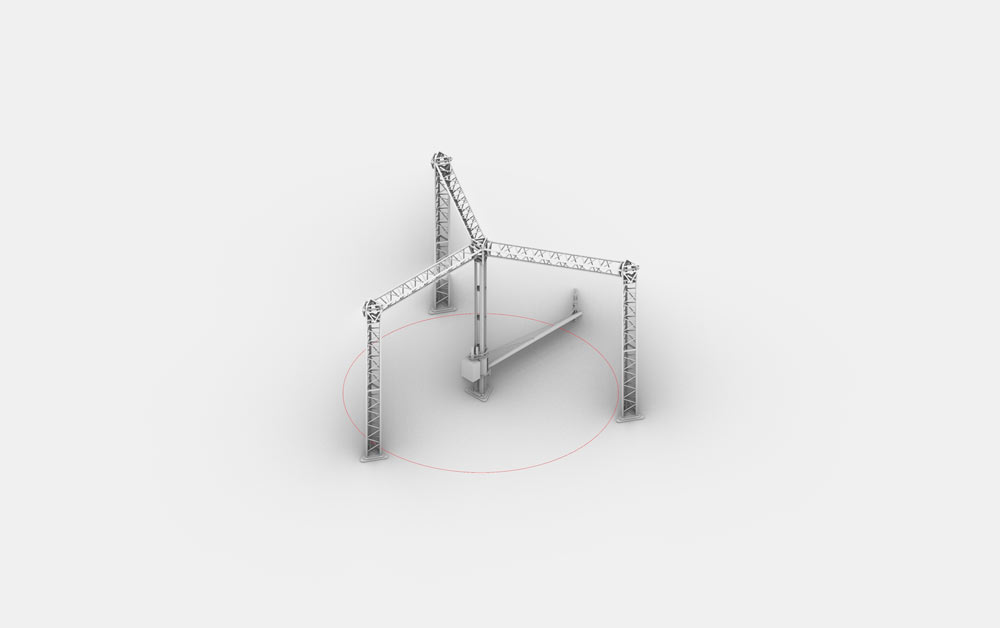

Then in 2018, the company created its Crane WASP 3D printer to help accelerate the development of the village. With a smaller footprint than the BigDelta WASP, a single module of the Crane WASP 3D printer has a print area of 6.60 m in diameter and a height of 3 meters. The Crane WASP can also be dismantled and reassembled for swift transport and on-site construction. It was used to successfully complete a small building for the technological village of Shamballa. The building, named Gaia, measured 21.6 feet in diameter and 9.8 feet tall. It is made of a cement containing 25% soil, sourced onsite, 40% straw chopped rice, 25% rice husk and 10% hydraulic lime.

Now commencing its TECLA project with MC A, WASP believes the housing model has the potential to provide a basis for creating autonomous eco-cities. “WASP takes inspiration from the potter wasp. We build 3D printed houses using earth found on the spot, under a sustainable perspective. The oldest material and a state of the art technology merge to give new hope to the world,” comments Massimo Moretti, WASP CEO. “Gaia, our first 3D printed house made with raw earth, was born a year ago. Today with our partners we are printing TECLA an entire eco-sustainable habitat. The planet is asking for a joint project that we share with Mario Cucinella.”

The 3D printed TECLA house

TECLA is designed by MC A, and engineered and built by WASP. It will reportedly be the first habitat built using multiple collaborative 3D printers, and the first house to be entirely 3D printed using locally sourced clay. This will help limit industrial waste, therefore offering a sustainable model that WASP hopes will boost the national and local economy. Furthermore, the TECLA house is designed to adapt to multiple environments, and can be built by the Crane WASP 3D printer in one job, thus speeding the construction process.

TECLA was developed using research from the School of Sustainability – a professional school focusing on sustainable architecture, founded by Mario Cucinella. The research was further supported by MA students from the Sustainable Environmental Design programme at the Architectural Association School of Architecture in London.

Working together, the researchers explored the causes and effects of homelessness, and the potential for technological advances to help in achieving a suitable solution, based on different locations with varying climates. This helped to inform the design of TECLA, resulting in a flexible model that can adapt to any climate, while reportedly remaining energy-efficient in a way that traditional housing models are not.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows rendering of the TECLA 3D printed earth house at night. Image via Mario Cucinella Architects.