Robotics experts at the New York University (NYU) Tandon School of Engineering are designing a collective of robots equipped with 3D printers for autonomous and mobile construction.

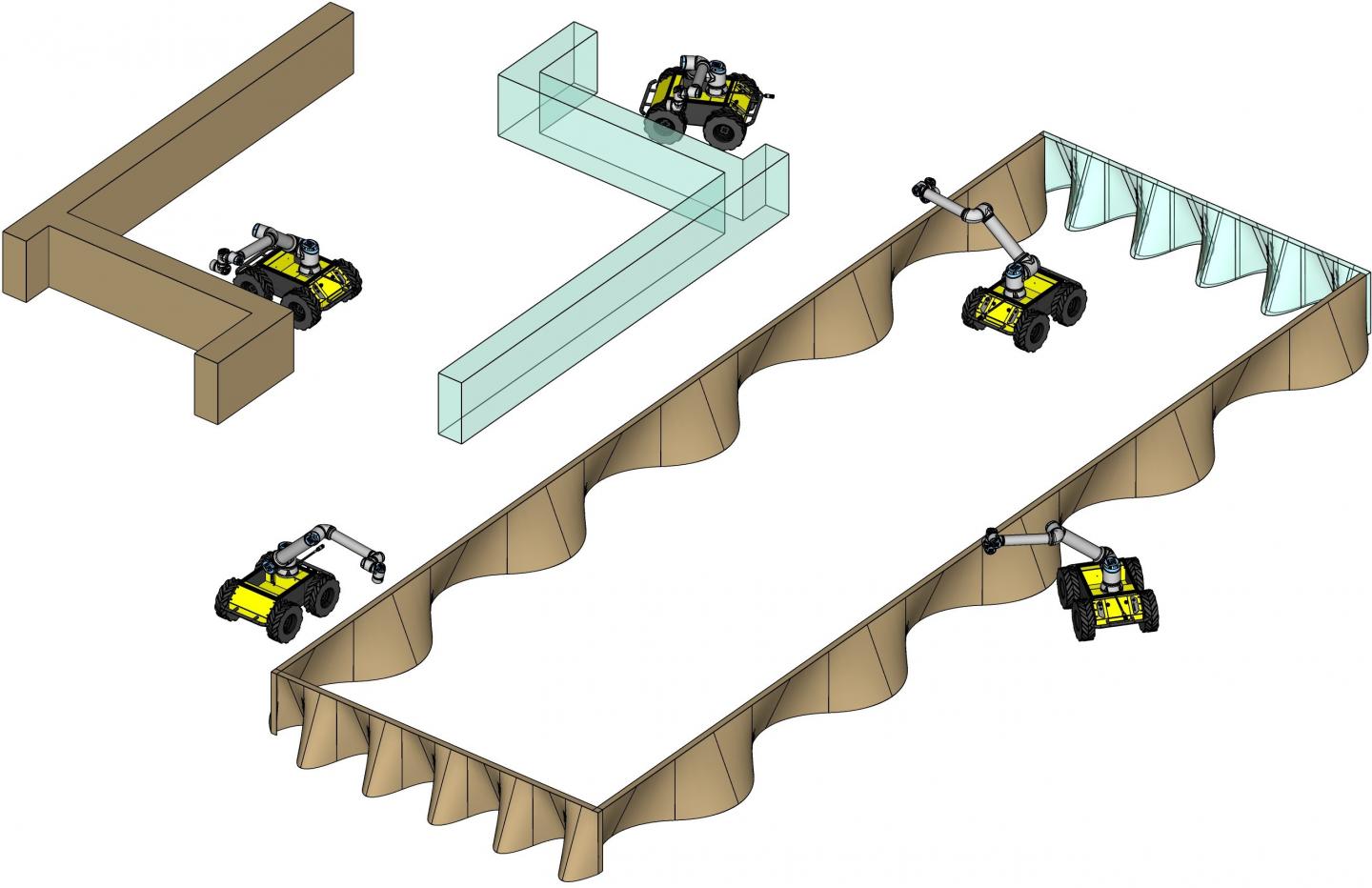

Specifically, the researchers looking at the creation of autonomous systems for 3D printers connected to the end of robotic arms. These arms will be attached to roving platforms for full mobility. The mobile 3D printers are designed to work in teams, through a concept called collective additive manufacturing (CAM). Using machine learning and AI, the robots can function as a unit with the potential of completing a variety of useful construction jobs, like repairing bridges, tunnels and other civic structures; or even work in ocean depths and disaster zones. The NYU team also claims that it may be possible for the robots to operate in space exploration activities in the future.

The research project is supported by a $1.2 million grant from the National Science Foundation (NSF), and is taking place at NYU’s Center for Urban Science and Progress (CUSP). Chen Feng, assistant professor at NYU Tandon’s Department of Civil and Urban Engineering and Department of Mechanical and Aerospace Engineering, states that

“To unleash the full potential of collective additive manufacturing, several scientific boundaries must be pushed, ensuring optimal deployment of multiple mobile robots that print large structures according to an engineered, virtual design.”

Making collective additive manufacturing viable

The research team, comprising of Chen Feng, Maurizio Porfiri, Ludovic Righetti, and Weihua Jin, is a multidisciplinary group of professors in the Departments of Civil and Urban Engineering, Mechanical and Aerospace Engineering, and Electrical and Computer Engineering at NYU. Each member will focus on different areas surrounding autonomy, control, real-time systems and networking, which are considered critical to making the CAM robots viable.

The first area centers on ‘Planning and Localization.’ In order for the 3D printing robots to operate together, they must be able to localize according to each of their respective positions, and the structures they are building. It is important that this is achieved without relying on global positioning systems, particularly for extraterrestrial applications, as these are only accurate to a few dozen feet. It is necessary for positional adjustments to be made fast, and accurate to a few millimeters instead. Feng will tackle this particular field, explaining that the goal is providing the robot with accuracy, efficiency, and adaptability to the environment and to real-time conditions.

“The robot must be able to move quickly to the printing area, observe the real conditions — such as uneven ground, since the real world isn’t planar — then make compensations immediately,” Feng explains. “And while we want to have a higher degree of accuracy in the structure area, the further you are from structure the less you need. This will involve a new kind of proactive localization.”

Moving on, the second key area is ‘Model Predictive Control.’ This focuses on making sure the mobile base and manipulator are efficient and stable enough to support fast and high quality 3D printing that can adapt to the environment in real-time. Examples include unexpected or unwanted variations in the real-world conditions at the site, or in the printer head as it deposits cement or other material. This subject is assigned to Righetti, who will work on developing real-time optimal control algorithms for each of the mobile 3D printers, allowing them to adapt to the environment.

“Each robot has to observe what is being printed, autonomously associate it with the project design, and recognize instantly if the printed structure has deviated from it, and by how much, and all the while decide what are the next best actions to ensure proper printing of the structure,” comments Righetti.

Autonomous cooperation between 3D printers

Finally, the researchers will also focus on ‘Printing and coordination.’ It is required that the motion of multiple mobile 3D printers are synchronized depending on the designs of the parts to be 3D printed. Therefore, the actual evolving structure, as it is being 3D printed, will act as a map for the physical coordination of the robots. Porfiri will work on developing a mathematical framework allowing for such a level of coordination. The framework will help the robots autonomously plan their actions within the physical environment, where they will concurrently be able to 3D print a structure with higher efficiency. This is especially important for the robots should they go on to complete extra-terrestrial construction activities on Mars, for instance, as there won’t be a remote server close enough to coordinate the robots manually.

Porfiri adds that “Different from drones flying in formation or autonomous cars keeping distance from each other, our mobile printers leave a unique footprint in the physical environment: the object being printed. My work will leverage this very footprint to establish effective algorithms for coordination and collective printing.”

Furthermore, Jin will be aiding the team’s overall effort by helping to develop composite materials that are suitable for mobile 3D concrete printing. To demonstrate the effectiveness of the 3D printer control algorithms, the research team plans to use the newly developed concrete materials with the CAM robots to 3D print a structure at NYU Tandon. The research project will also look to include the efforts of NYU students. Students will be able to participate in an industry workshop on CAM, and an outdoor public exhibition. They will also gain access to an open educational kit on CAM, K-12 desktop-scale CAM competition, and entrepreneurial activities.

Mobile 3D printing

Mobile 3D printing is not a new concept, with various companies and institutions having explored and integrated autonomous, moving robotics with 3D printing capabilities.

For example, Ambots, an Arkansas-based 3D printing technology and assembly provider, has developed a class of mobile robots capable of 3D printing, which the founders say will initiate a new kind of digital factory. The compact machines incorporate an FDM/FFF 3D printer and four omni wheels, enabling the Ambots to move across the X and Y axes, with two ADNS-9800 laser motion sensors controlled via a wireless connection.

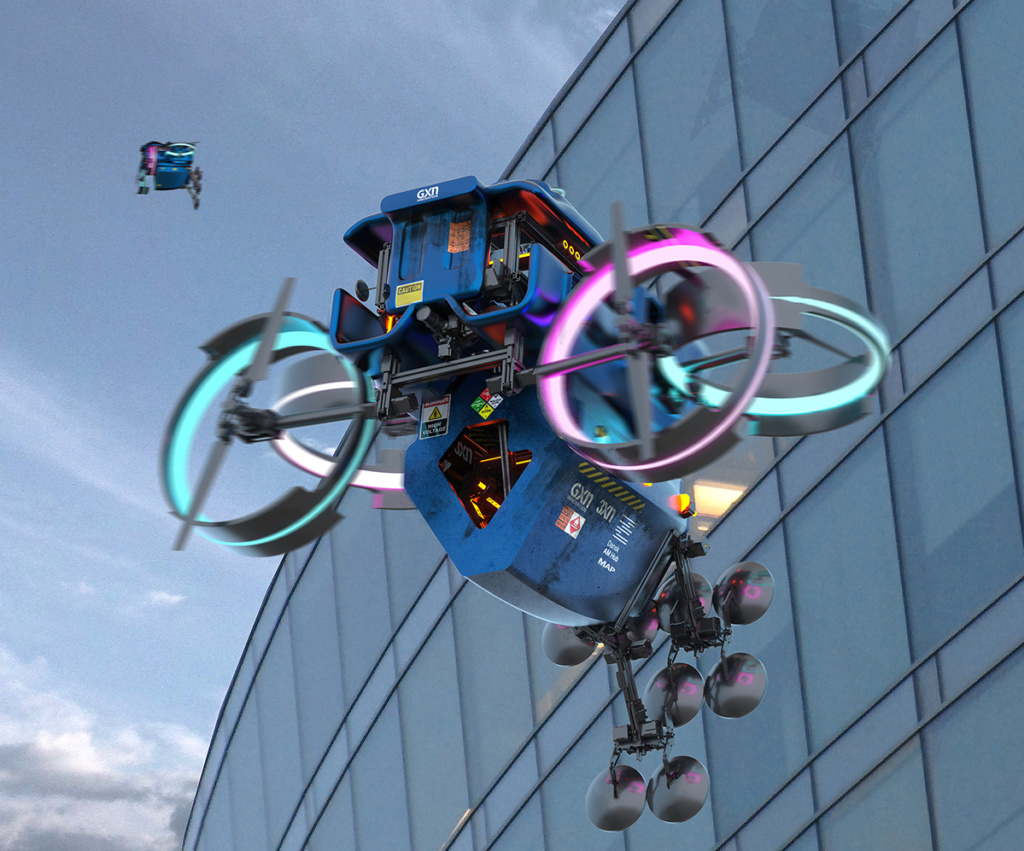

GXN Innovation, an independent research subsidiary of Danish architecture firm 3XN, has also explored how to make 3D printers autonomously mobile. By creating physical and virtual hacks of existing 3D printers and inscribing them with mobility, the group’s research focuses on meeting the global challenges of population growth and climate change, which poses a threat to buildings, infrastructure and cities across the world.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows collective additive manufacturing robots. Image via NYU Tandon.