GXN Innovation, an independent research subsidiary of Danish architecture firm 3XN, has launched ‘Break the Grid’, a new initiative exploring how to make 3D printers autonomously mobile. Collaborating with the Danish AM Hub, Denmark’s platform for digital and additive manufacturing, and MAP Architects, a Copenhagen-based architectural design studio, the research program will seek to create physical and virtual hacks of existing 3D printers.

The aim of the research is to establish more efficient methods of dealing with urban, social and environmental change. By modifying 3D printers to autonomously move, the design partners hope to meet the global challenges of population growth and climate change, which poses a threat to buildings, infrastructure and cities across the world.

“Freeing 3D printers to meet these challenges could be a revolution in the making,” explained Kasper Jensen, Founder of GXN.

“By enabling 3D printing robots to crawl, swim, and fly, we can address pressing environmental threats around the world at lower cost and with greater efficiency.”

Break the Grid is also a part of the Moonshots initiative from Danish AM Hub, which supports projects working towards pushing the limits of 3D printing in order to create a better world.

Saving the future using 3D printing

GXN, established in 2007 by 3XN, seeks to create new approaches to environmentally beneficial design while pushing the boundaries of architecture. The Danish AM Hub is supporting GXN in order to carry out its own goals, which revolves around providing advice on additive manufacturing to the Danish ecosystem, with the aim of getting industry to see the multifaceted potential of 3D printing.

The foundation of the Break the Grid project is based on three scenarios presenting global challenges where autonomous additive manufacturing would be crucial. Members of the research team envisioned a near future where technological advances in robotics and machine learning have mobilized 3D printers to move autonomously through our environments to solve these challenges. Then, the team created mobile mechanical prototypes of 3D printers using existing sensing and printing technology. With the prototypes, different virtual hacks were explored to enable mobile 3D printing on land, underwater and in the air.

The first global challenge proposed by the project addresses the deterioration of global infrastructure. Specifically, it targets micro-cracks; a starting point for further damage in concrete structures. Water and oxygen can enter the cracks and corrode the concrete construction. To respond to this scenario, the project team hypothesize that 3D printers can use a porous filler mix to repair the micro-cracks. The filler would be mixed with a fungus called ‘Trichoderma Reesei’, which enables the formation of calcium carbonate. This is useful as calcium carbonate is often used in industrial settings to neutralize acidic conditions in both soil and water, and can therefore prevent corrosion. Autonomous hexapods equipped with the 3D printer would scout urban and remote concrete infrastructures, identifying micro-cracks to repair before further damage can occur.

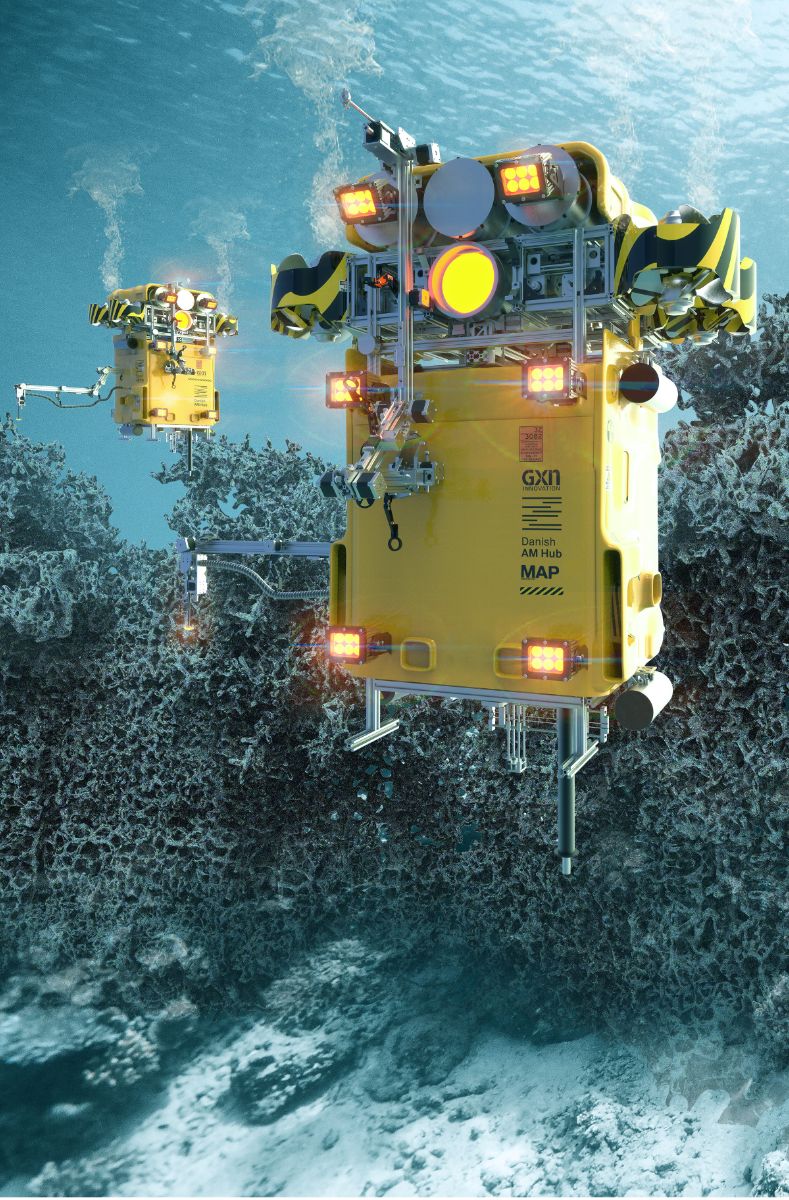

A second global challenge centers around the damage caused by climate change on coastal habitats. It is said that over 10 percent of coastal populations live less than 10 meters above sea level. They are considered increasingly vulnerable to coastal storms and tsunamis. The researchers used a synthetic glue with the same properties of a specialized adhesive produced by oysters, based on research from Purdue University and the University of South Carolina. Break the Grid considers whether 3D printing ROVs could go underwater to mix the glue with ocean floor sands. This would create a wet-setting binder, that can be used to 3D print artificial reef structures in order to protect the coasts while also providing habitats for marine life.

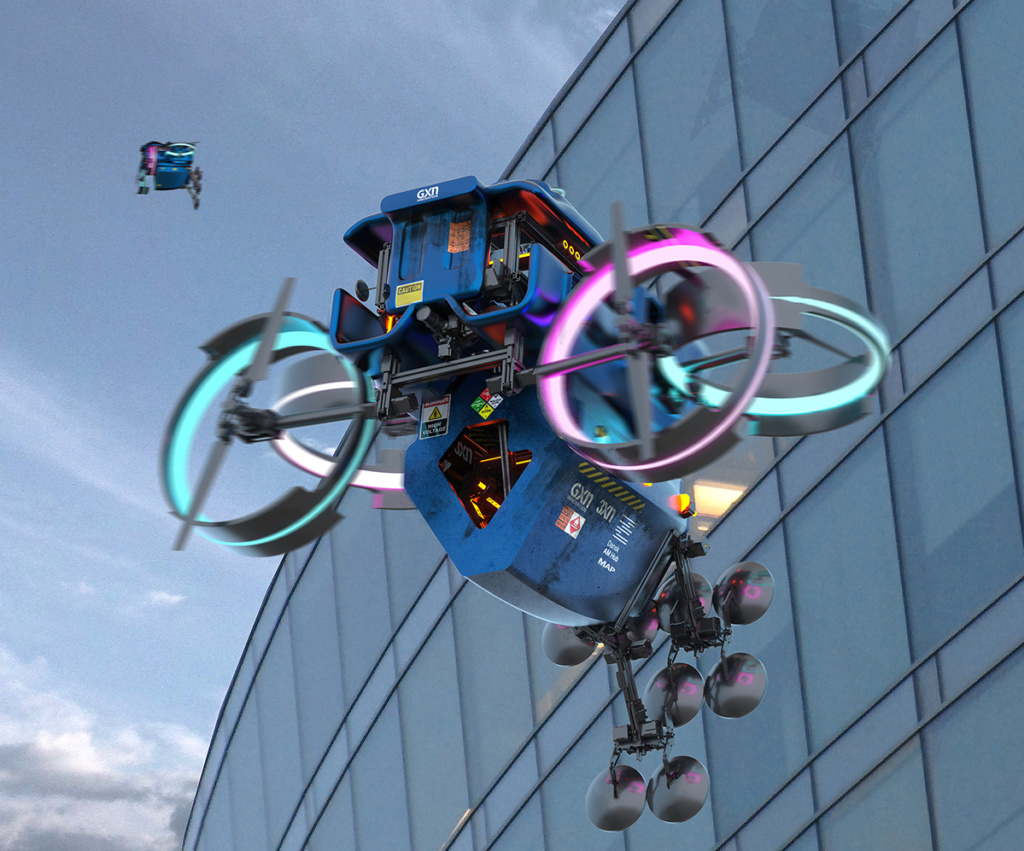

The final global challenge attempts to deal with the heat and energy loss resulting from decaying high-rise buildings in major cities. Many of these building’s facades require repair or better insulation, in order to prevent further degradation and escaping heat. To create new thermal insulation for the old buildings, the team are exploring the use of functionally graded materials by combining glass with high-performing polymers, based on research from the Royal College of Art in London. In order to apply the insulation, the Break the Grid team conceived a drone-based 3D printing system to identify and fill thermal bridges in the older high-rise buildings. This would allow for lower costs due to reduced labour and less human interaction, leading to an efficient material-based solution.

“Converging technologies are enabling new approaches to construction,” commented Mads Kjøller Damkjær, CEO of The Danish AM Hub Fund. “We hope to inspire the additive manufacturing industry to envision new possibilities, which will require combining design and technology to shift our values and our current ways of thinking.”

3D printing helps to construct a better world

Many construction companies and design studios have utilized 3D printing in order to overcome some of the world’s most pressing issues with architecture.

For example, 3D printing has been used to create housing for low-income families in Latin America, in what is dubbed as the “world’s first 3D printed community”. A response to the global housing crisis, the project is spearheaded by San Francisco-based design studio Fuseproject, Texan construction technologies company ICON, and New Story, a non-profit organization fighting homelessness.

Furthermore, the Conference Board of Canada, a not-for-profit think tank based in Ottawa, released a report in November 2018 investigating the potential of 3D printing in construction to overcome the country’s most extreme environments. Targeting Canada’s North, the research is seeking to improve people’s quality of life by providing a more cost effective approach to the construction of homes.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a drone-based 3D printing system. Image via GXN.