After working for HP’s Digital Signage division (the same one that announced the new 3D printer and creative ecosystem) in Hong Kong, Gilad Yron joined Objet about five years ago. As general manager and managing director he oversaw the merger with Stratasys in the Asia Pacific region to then return to Israel and take up a position as VP of business development, overseeing the product management and product marketing teams. So my first question to Gilad, as I have not had a chance to actually prepare this interview, is… what exactly is a product in 3D printing?

When your business is using products to make products used to make product prototypes for others to make more products, the answer is a lot more complex than you may initially think. “It is almost a philosophical question,” says Gilad. “In 3D printing, products are generally considered to be the 3D printers and consumables but more and more today, we are trying to move away from this simplistic approach and are thinking more in terms of solutions.”

A NEW PRODUCT CONCEPT

“We are trying to create many layers of value and dimensions to our products in order to better service our clients,” he added. This means that for Stratasys a product can now be made up of 3D printers and materials as well as workflow, software elements, services, and so on. For the current largest manufacturer of 3D printers to think in these terms is a significant step and the trend is not just apparent at Stratasys. HP’s announcements was headed in this direction as is Autodesk’s Spark ecosystem.

A lot has to do with the recent GrabCAD acquisition, which together with Thingiverse (possibly the main reason why Stratasys paid $400 million for MakerBot) gives Stratasys control over the largest, open source 3D model databases as well as access to a very large and powerful web-based software infrastructure. Gilad never said it specifically but my impression is that Stratasys’ big yet unannounced announcements at the upcoming Euromold event will have a lot do with this aspect.

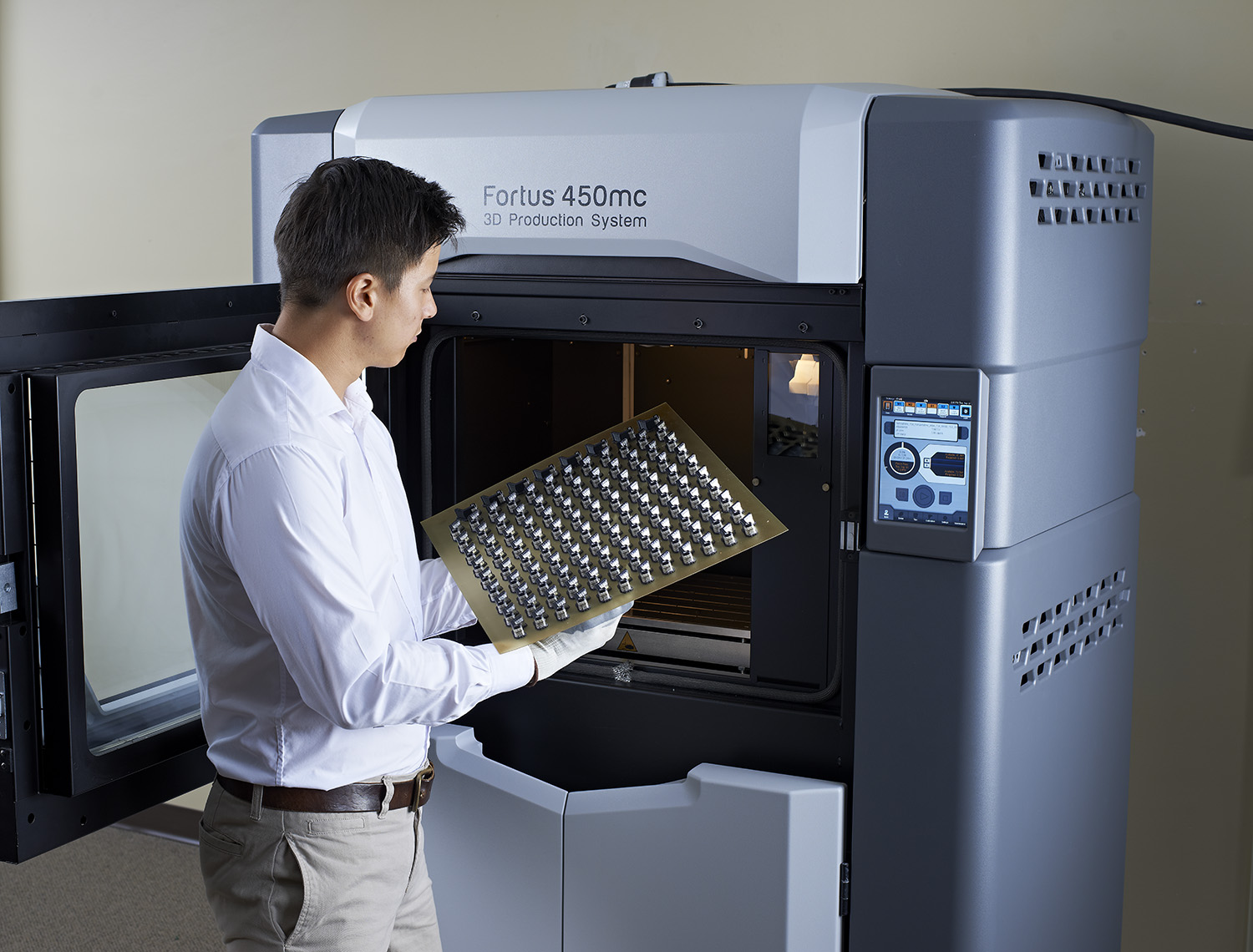

To do that it has so far announced a total of 24 new products during this past solar year and the company stresses that these are all products that are already on the market or will be very soon. “It is the Stratasys way,” says Gilad, “our main asset is our business integrity. We want to deliver true value to our customers and we want to offer products that are accessible and can also provide a leap in performance.”

50 YEARS FROM NOW

Without revealing too much ahead of Euromold, Gilad does not shy away from any question and their possible implications. His enthusiasm is the same as that of any maker and 3D printing fan. “We are in the midst of an amazing revolution,” he says. “How fast it will happen I don’t know but let’s play a game and envision where 3D printing will be 50 years from now. Whatever we today imagine might happen with 3D printing in 50 years it will have happened and I think we can be relatively certain that 3D printing will be present in people’s lives and will continue to bring significant value at many levels while disrupting manufacturing processes and creating a meaningful impact on our lives.”

This does not mean 3D printing will be disrupting companies and taking away jobs. Gilad thinks it will be the opposite: it will disrupt the processes and create many new possibilities. He knows traditional manufacturing will still exist 50 years from now and that while some may be slow to adapt and suffer, many companies will benefit from the new business models and products possible with 3D printing. “It will create a lot of jobs and a lot of work by empowering people and companies to do more,” Gilad says.

Stratasys new “products”, as in solutions, will work to continuously improve the entire 3D printing process, from design to finish to meet the manufacturing industry’s demands. Gilad feels that we have already crossed a tipping point and that people are now looking at the entire process. “That means – he says – that we, like our competitors, have to work on that to improve and automate it as much as possible all the way to post-processing.”

OPEN STRATASYS

“There is always going to be a healthy tension between the open source community and other commercial models and I think we have been able to balance it quite nicely,” Gilad continues. “We own two of the Web communities, Thingiverse and GrabCAD, that are among the biggest sources of open innovation worldwide. At the same time – he adds – we need to be able to sustain our business model through a closed system. I don’t think a single business model can ever completely take over the other.”

One way Stratasys is focusing on innovation is by funding projects where students collaborate with industries to solve problems. For example once such recent project was at a school in Israel which saw the students study biomimicry to develop a system for filtering bacteria in water pipes. The school had just purchased a MakerBot desktop 3D printer and the students used it to develop a pipe inspired by the way sharks deal with bacteria on their own skin. Other ways are by studying new technologies, such as 3D scanning, and by conducting its own R&D. The company is generally thinking years ahead. And the confidence with which they speak about their leading role in the market makes me think that we are going to see a lot of interesting innovation in the years to come, starting at Euromold next week.