Leading 3D printer OEM Stratasys has announced the Performance Partner Program which connects auto racing, competitive sailing and supersonic travel teams leveraging additive manufacturing.

As part of this program, the company has also facilitated the Performance Partner Summit in Speedway, Indiana, where the partners can collaborate on competitive applications of FDM technology. Pat Carey, Senior Vice President of Strategic Growth at Stratasys, stated:

“We’ve all seen a 3D printed helmet here, a bicycle seat there. But never before has there been a focused, collaborative group of the who’s who of these industries – dedicated to advancing the use of additive manufacturing across these high-performance environments. That is…until now.”

The Performance Partner Program and Summit

Presently, the Performance Partner Program consists of 11 partners. This includes the American professional racing group, Team Penske, and Don Schumacher Racing (DSR), as well as Colorado-based aerospace company Boom Supersonic.

The remaining partners are Andretti Autosports, Joe Gibbs Racing, McLaren Autosports, Arrow Schmidt Peterson Motorsports, American Magic, Jay Leno’s Garage, Kindigit Design, and SEMA Garage.

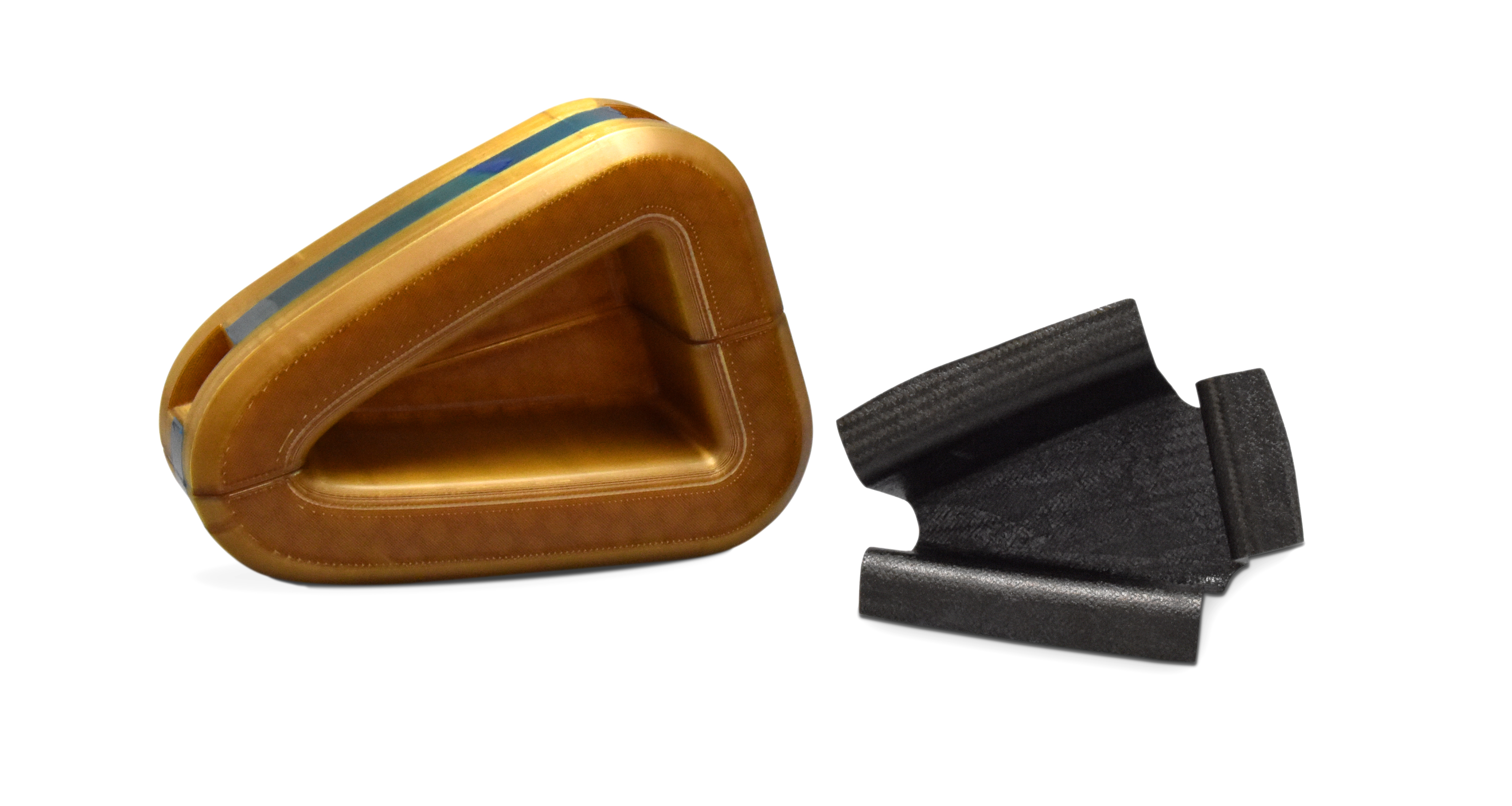

According to Carey, the Performance Partner Summit allows for a “formal environment of collaboration as partners explore advanced approaches to get faster, become more competitive, and go farther than ever before.” Here, the members showcased the various applications of 3D printing to create hollow composite and high strength parts as well as forming tools. This was done with materials such as FDM ULTEM 9085 and Stratasys ST-130 sacrificial tooling filament, and FDM Nylon 12 Carbon Fiber.

FDM creates a competitive edge

Recently, Boom Supersonic extended its partnership with Stratasys to further accelerate the adoption of additive manufacturing for flight hardware by utilizing Stratasys’ Aircraft Interiors Solution (AIS) package alongside the F900 3D printer.

Prior to this, Team Penske announced further tooling collaborations with the company with the use of the Fortus 380mc Carbon Fiber Edition (CFE) industrial 3D printer and the F900. DSR and Arrow Schmidt Peterson Motorsport also integrated the Fortus 450mc and F370 3D printers to accelerate design iterations, workflows, and final part production.

For competitive sailing, the New York Yacht Club, American Magic is leveraging the Fortus 450mc, to 3D print high-speed, light-weight production parts for each of its vessels. Carey continued, “Each [team] is maximizing the use of FDM to match extreme design and manufacturing requirements.”

“Our partners are converging not only to explore how each is capitalizing on additive manufacturing, but to get a closer look at key applications and products to make additive manufacturing even more powerful.”

Stay updated with the latest in additive manufacturing by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Stratasys demonstrating 3D printing applications for McClaren at TCT 2017. Photo by Michael Petch for 3D Printing Industry