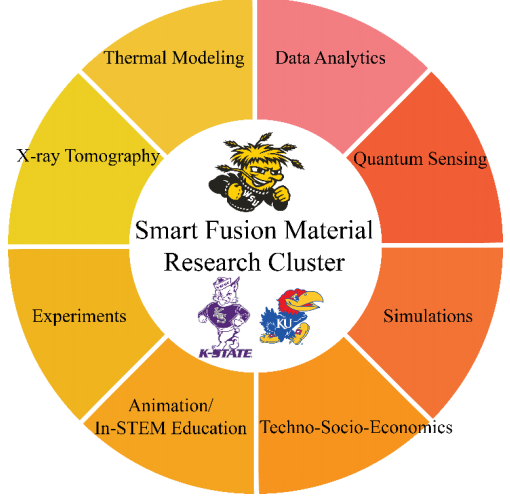

Interdisciplinary teams hailing from Wichita State, the University of Kansas, and Kansas State University, are joining forces to form an entrepreneurial incubator that aims to explore sustainable material design and manufacturing processes for metal 3D printing through applying an emerging data analytic algorithm.

Named the Smart Fusion Material Research Cluster (SFMRC), the team’s mission is to stimulate research, education, and practice within sustainable manufacturing through advancing science, technology, and policy elements of computational material design and 3D printing. To achieve this, they will deploy novel data analytics, computational approaches, and diagnostic tools in what the team calls a socio-techno-economic approach – understanding material design and manufacturing as an ecological system where individual, technology, infrastructure, and social environments intersect with each other.

“Sustainable material design and manufacturing are grand societal challenges, since those are essential to technological advancement and economic growth in multi-billion industries, economic sectors, and national security,” said Dr. Gisuk Hwang, Principal investigator on the project and Associate Professor of mechanical engineering at Wichita State.

“The mission of the proposed research cluster is to investigate coupled interactions among science, technology, socio-techno-economic, public, and environmental policy in material discovery through collaborations with intra-KBOR members and innovation campus, and to train students and industry professionals to empower the future workforce.”

Advancing metal 3D printing

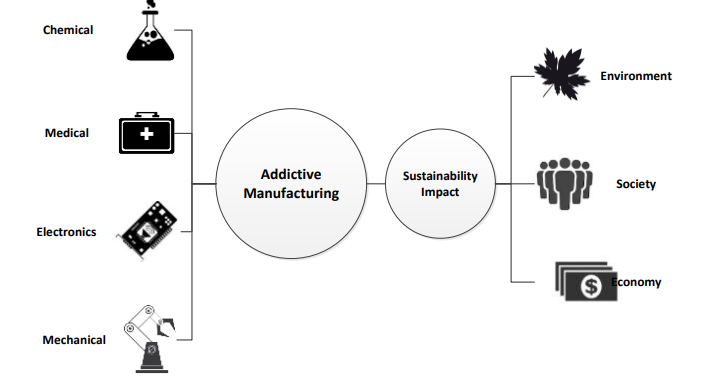

According to Hwang, current challenges to metal additive manufacturing include a lack of understanding of the relation between material properties, 3D printing process parameters, the microstructures of 3D printed parts – pore size and structure, and phase transformation – and mechanical properties, such as strength, fatigue, and thermal stress. For simplicity, the Hwang refers to this area of the cluster’s research as material-process-microstructure-mechanical relations, and promoting fundamental knowledge of these interconnections is one of the main short-term goals of the project.

To do this, the team will develop new data analytic algorithms capable of understanding the relationship between numerical, text, and image data gleaned from metal additive manufacturing materials, and combine this data with diagnostic and computational simulation tools to see where material optimization advances could be made. The researchers will then investigate the socio-techno-economic factors for facilitating the commercialization of developed materials.

The SFMRC will explore both metals that are already widely used in metal 3D printing, as well as metals that present more of a challenge to optimize for various additive manufacturing applications, such as aluminum, nickel-based alloys, titanium, copper, and magnesium.

“Currently, we are trying to understand the material-process-microstructure-mechanical relationships in trial and error based experiments, which is a very expensive process,” Hwang explained. “We plan to come up with good predictive tools using the data analytic approach to reduce the cost and stimulate the commercialization [of the materials].

“Also, we would like to understand the bottlenecks of this technology on the commercialization within social sciences and policy side.”

Desired project outcomes

By the end of the project, the SFMRC hopes to have developed a database system that details the material-process-microstructure-mechanical relationships for a variety of materials deployed within metal 3D printing. Users will be able to purchase the printing parameters laid out in the database to use for their own projects.

The team also hopes to develop a quantum sensing device capable of monitoring real-time local temperatures within the powder bed during the 3D printing process. According to Hwang, the device will deploy quantum physics to measure the local temperature of powder beds in a non-destructive way. The plan is to then commercialize the quantum sensor to provide users with a non-destructive diagnostic technology.

The project also has an educational element, and will seek to facilitate best practice, evidence-based learning and teaching strategies within the universities involved in the project. SFMRC researchers will also work wth elementary, middle school and high school teachers and students to make metal 3D printing more relatable and accessible.

Hwang said: “The research component is synergistically implemented into the education component so that whatever they find from the research, we can just push for an entrepreneurship mindset to come up with innovative ideas for business and then economic activities.”

Material research and development

A plethora of material-focused research is currently underway within the field of metal 3D printing, and there have been significant advances in recent years.

In 2019, scientists at Lawrence Livermore National Laboratory (LLNL), SLAC National Accelerator Laboratory (SLAC) and Ames Laboratory used X-ray imaging to identify the causes of defects in metal 3D printed parts and understand how such flaws can be prevented. Since then, the hydrogen embrittlement of metal 3D printing materials has been investigated by researchers at the University of Texas at San Antonio, and a study by the University of Washington looked into the effects of metal powder reuse on 3D printed part quality.

In April last year, scientists from Texas A&M University discovered a method of 3D printing martensitic steel free from porosity with what was claimed to be the highest tensile strength reported to date for any 3D printed alloy. Reducing defects in 3D printed metal parts has also been investigated elsewhere at LLNL, where researchers were able to reduce the ‘splatter’ of rogue material during the Laser Powder Bed Fusion (LPBF) process and lessen loose powder interaction with freshly fused material, in order to decrease defects and increase the quality of each metal layer.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows schematics of the planned convergent research cluster. Image via SFMRC proposal.