Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC), the National University of Singapore (NUS) and the country’s Economic Development Board have invested $13.2 million in a new specialist biomedical facility.

The National University of Singapore Centre for Additive Manufacturing (AM.NUS) has been opened to strengthen Singapore’s international position in the field of 3D printing.

It is already working with a number of commercial partners for research and product development.

A cluster of innovation

Inaugurated in 2015, NAMIC is an initiative from Nanyang Technological University (NTU) designed to fuel 3D printing innovation in partnership with the Singapore government.

So far, the initiative has successfully funded a number of AM projects focusing on metal 3D printing and the aerospace sector.

With labs strategically placed in NUS’s Yong Loo Lin School of Medicine and the Faculty of Engineering, the new AM.NUS center harnesses the expertise of multidisciplinary students and professors across medicine and dentistry.

AM.NUS will bring together NUS technologies with industry expertise, enabling the accelerated translation of NUS technologies into innovative healthcare products and services

Goals for the facility are wide-reaching, encompassing all potential areas of 3D printing application from medical devices, to medication and tissue engineering.

Dr. Lily Chan, CEO NUS Enterprise, explains “AM.NUS will bring together NUS technologies with industry expertise, enabling the accelerated translation of NUS technologies into innovative healthcare products and services. The Centre is already working on a total of 17 collaborative projects, and has raised about S$4.7 million ($3.5 million) in additional project funding.”

Hearts and brains

Following the opening of the AM.NUS, four local companies signed collaborative MOU’s with the center.

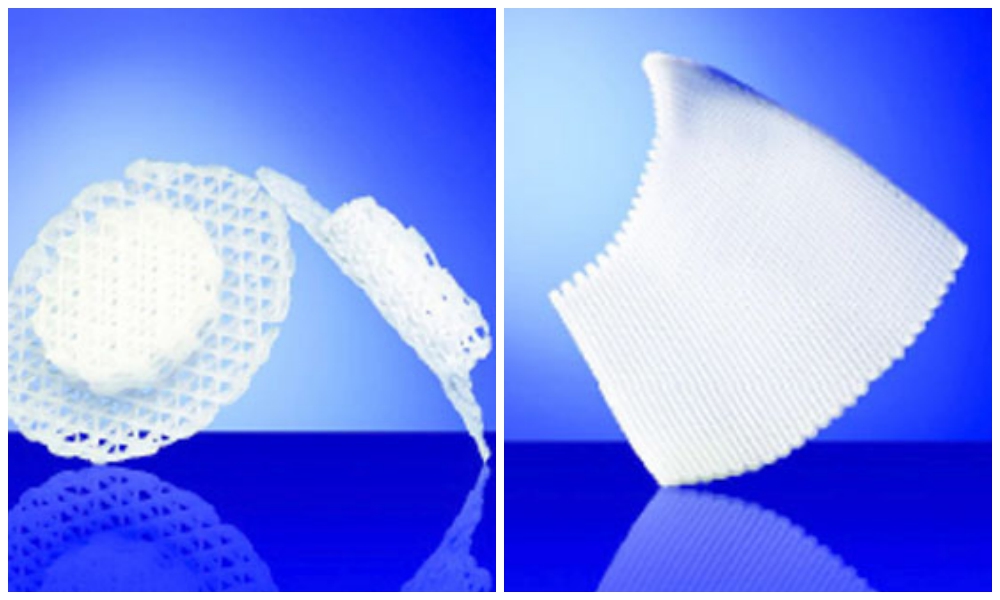

A certified provider of Stratasys, Materialise and Arcam services, Creatz3D has partnered with AM.NUS on a project to develop custom 3D printed organs models for use in training and surgical simulation.

Osteopore International will be working with the AM.NUS center to clear clinical trails for 3D printed orthopaedic devices. Osteoplug and Osteomesh devices developed by the company are designed to be used as implants in brain surgery, and promote the regrowth of skull bone.

Mid-size medical device company Dou Yee Enterprises and precision engineering company Forefront Additive Manufacturing have also entered into partnerships with the AM.NUS center.

Personalized healthcare is the future

“As a cluster founding member together with NTU’s Singapore Center,” says Dr Ho Chaw Sing, Managing Director NAMIC, “the NUS Center for Additive Manufacturing will play a vital role in NAMICs translational research and industry adoption efforts, further strengthening Singapore’s efforts to become a global 3D printing technology hub.”

Dr. Chaw adds, “As the industrialization of 3D printing gains momentum, our goal is to help the sector achieve better patient outcomes, addressing the needs of our bio-medical and patient community with cost-effective and personalized healthcare solution.”

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Sign up to our 3D printing jobs site now to take your career to the next level.

Featured image: A new heart for the NAMIC. NAMIC partners Creatz3D hold custom 3D printed models. Photo via Creatz3D