Siemens has announced it has now fully integrated Materialise’s 3D printing software into Siemens NX. Headquarted in Belgium, Materialise is a 3D software and solutions provider and are well-known in the 3D Printing Industry for their Magics 3D Print software.

The two European companies, signed a partnership in January and have now disclosed the results of the collaboration with Materialise software introduced initially in the most recent version of Siemens NX, NX 11.0.1.

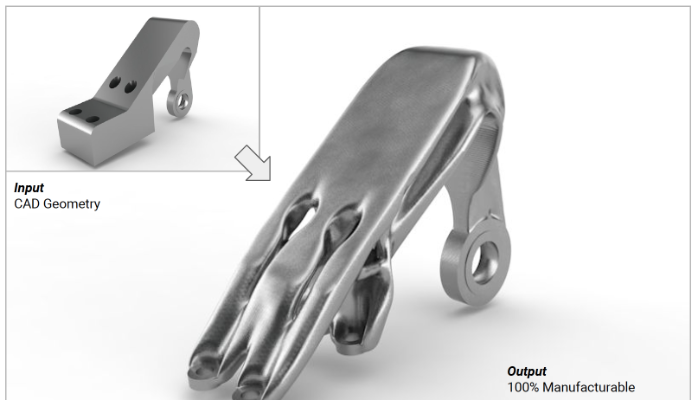

Siemens has leveraged Materialise’s expertise in preparing digital designs for 3D printing and also recently announced a partnership with Colorado company Frustum to integrate their topology optimization generator.

Leap forward for mainstream manufacturing

By adding Materialise’s Magics 3D Print technology, Siemens NX will now offer lattice technology, design of support structures, build tray preparation and 3D nesting.

Zvi Feuer, senior vice president of Manufacturing Engineering Software for Siemens PLM Software said the announcement, “represents a huge leap forward in making additive manufacturing a mainstream production practice for our customers.”

Feuer explains this is because, prior to this, “the additive manufacturing process required manufacturers to work with two separate systems – one for product design, and another to prepare that design for 3D printing.”

Siemens’ newest iteration of their NX software will combine the processes and thereby attempt to mitigate errors and provide a time efficient solution. As a result, Feuer believes Siemens is, “helping to expand the adoption of additive manufacturing as a universally accepted production tool.”

Simplifying the workflow

Siemens NX software is widely used for industrial manufacturing, from designing automobiles and aircraft to consumer products, while Materialise’s software encompasses the wide range of additive manufacturing processes from metal powder bed fusion to material jetting.

Johan Pauwels, Executive Vice President at Materialise explains that the collaboration is “optimizing and simplifying the workflow for design, engineering and manufacturing of components.” Pauwels added,

We’re pleased to partner with Siemens, who truly understands large-scale industrial manufacturing environments and shares our belief that designers and engineers can create better products if additive manufacturing is embedded into their mainstream business processes.

Siemens is indeed familiar with the benefits of 3D printing for industrial manufacturing as the conglomerate has 3D printed a functional impeller for a nuclear power plant in Slovenia and 3D printed gas turbine blades.

German metal additive manufacturers Trumpf has already begun incorporating Siemens NX software and it is likely other companies will now follow suit.

If you haven’t already, make sure to vote in the 3D Printing Industry Awards and if you’d like to attend the event, tickets are available here.

For the latest 3D printing news, sign up to our newsletter and follow us on twitter and Facebook.

Featured image shows 3D printing workshop in Finspong. Photo via Siemens.