This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

Cristina Sesma is the Marketing Manager at MachineWorks Ltd., the makers of a polygonal solid modelling software toolkit called Polygonica.

3D Printing: The Next 5 Years by Cristina Sesma

In 2011, when MachineWorks’ polygonal solid modelling software toolkit Polygonica entered the 3D printing world, there was still hype about consumers becoming manufacturers thanks to 3D printing, a printer in every home. However, the dream never quite materialised for reasons of usability and the practicalities of the technology.

Even 3D printing professionals struggled to produce quality and cost-effective parts. There is no denying that any 3D printing process conveys a great challenge and demands a great deal of expertise, as with any other manufacturing process.

Materials are expensive and have limitations, a quality finish is only plausible with added post-processing, time taken printing is unacceptable and there are no economies of scale in the additive manufacturing process, so, where did 3D printed parts succeed?

Prototyping, customising, designing

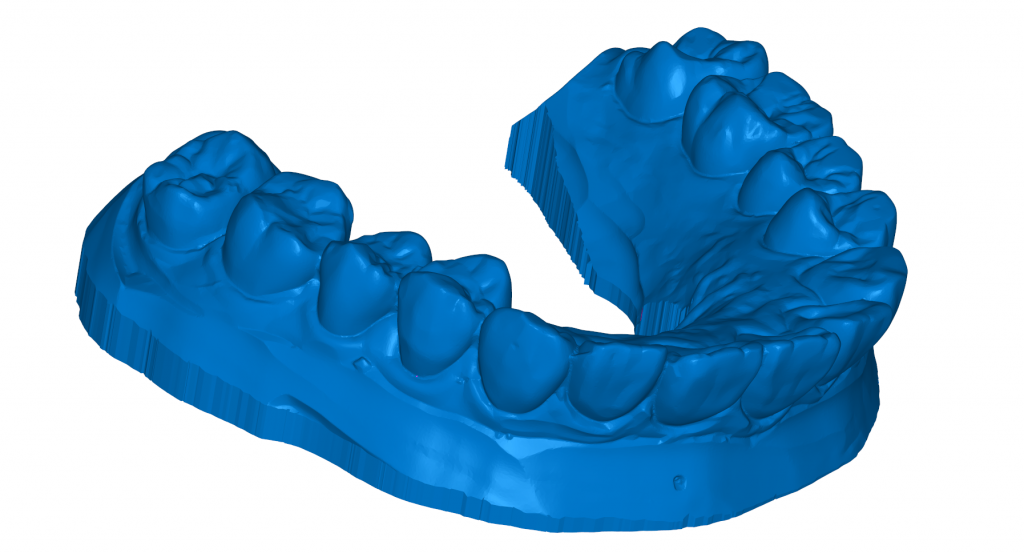

3D printing was a disruptive process, it challenged the way we design by expanding the possibilities of what it can be manufactured, it allowed to produce personalised parts for unique problems, it facilitated and economised the ability to produce, test and present new ideas in the shape of products.

What about software? MachineWorks’ simulation software has been integrated into CNC hardware and software manufacturers since 1994. At that time, our customers had the exact same problems fixing STL files that 3D printers encountered years later.

They needed watertight models to be able to run our simulation so we made their problem ours by developing an engine that automatically solved polygon mesh processing problems. When we approached hardware manufacturers in the 3D printing world, we found out that many would send customers to external software suppliers so that they could use their printers.

Software was one of the many annoying barriers that users had to resolve in order to 3D print, a bottle neck of open models and intersecting triangles full of noise that needed hours of manual.

But that’s in the past, how about the future?

Ahead lies the industrialisation of 3D printing, a real integration of additive and subtractive manufacturing in the shop floor. The remarkable advancements in metal printing and the investment made by multinational manufacturing giants through the acquisition of 3D printer companies will only accelerate this process.

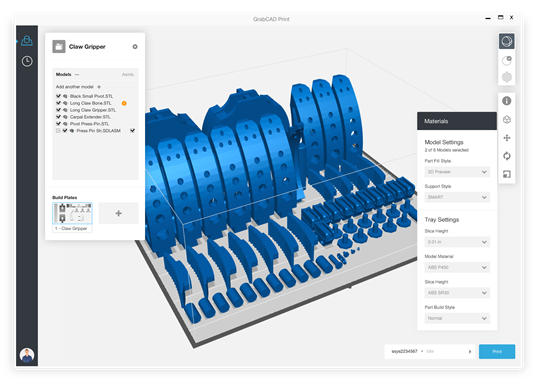

And, what about the software? Many leading hardware manufacturers have decided to embrace software and, in particular, component technology. They are wanting to protect their intellectual property, they want to form tighter relations with their own customers and they want to be in control.

The beauty of component technology is that they don’t have to start from scratch, they can optimise the process as they know their machines best and they can access the market quickly while protecting their know-how.

There is a still a long way until users can experience pressing a button and forgetting about the clever software running in the background but we are heading in the right direction.

The challenges have not changed but evolved. 3D printed parts still need to be produced cheaply, robustly, precisely and in a timely fashion but now, additive machines also need to be embedded within the fabric of the rest of the industry.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information. For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels.

Don’t forget that you can vote now in the 1st annual 3D Printing Industry Awards.

Can you find more information here about Polygonica.

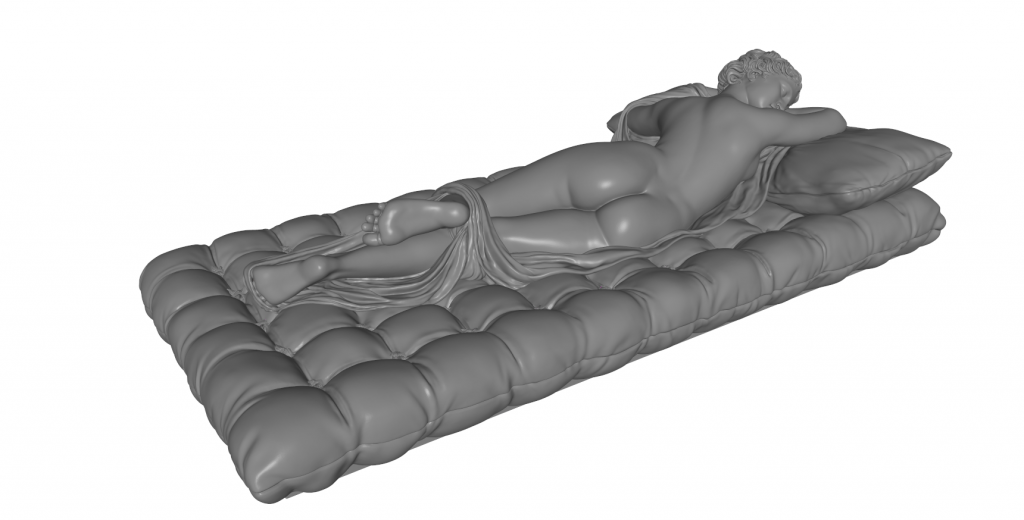

Featured image shows some of the features of Polygonica.