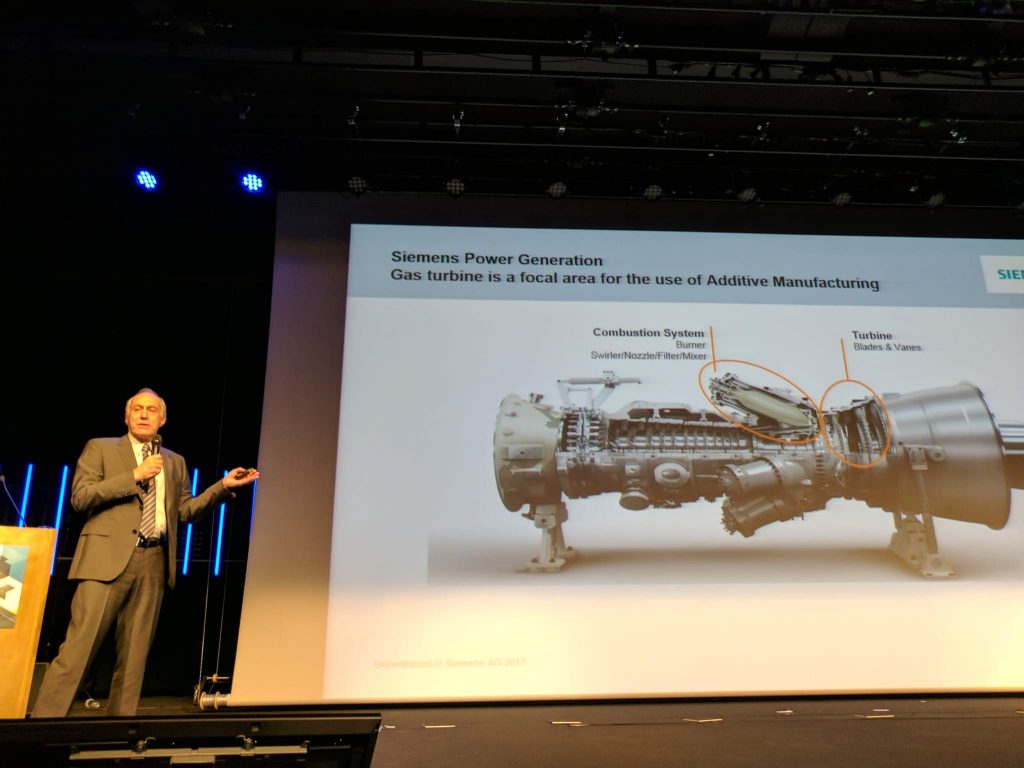

Siemens has unveiled plans to, “accelerate the adoption of 3D printing as a mainstream production method for industrial parts.” With a new digital part manufacturing platform the German company plan to bring on-demand product design and 3D printing production to the global manufacturing industry.

The part manufacturing platform under development by Siemens’ product lifecycle management (PLM) software business furthers the company’s, “comprehensive vision to provide the industry’s most complete set of seamless tools to support the global additive manufacturing industry.”

As previously reported by 3D Printing Industry, Siemens has already integrated 3D printing software from Materialise, topology optimization generation from Frustum, metal 3D printing from Trumpf (and others) and is working with Stratasys.

The industrial user base of Siemens PLM software includes, “over 15 million licensed seats and more than 140,000 customers worldwide.”

Seamless technology solutions for distributed industrial additive manufacturing

One use case for the platform is given as linking part buyers to micro-factories. In such an example, “the platform would enable members to 3D print production parts on-demand where-needed across the world. In addition, the platform will include collaborative capabilities to help streamline the co-innovation process and accelerate the adoption of 3D printing as a mainstream production method for industrial parts.”

Tony Hemmelgarn, President and Chief Executive Officer, Siemens PLM Software said,

Siemens is one of the only companies addressing the diverse needs of all additive manufacturing market participants – from designers and engineers, to manufacturers, 3D printing machine OEMs, material vendors and software providers – with a comprehensive set of seamless technology solutions for distributed industrial additive manufacturing and co-innovation.

The platform will, “create an online ecosystem made up of highly qualified members from a variety of areas such as product designers, job shops, part buyers, 3D printer OEMs, material suppliers, expert services providers, micro-factories and much more.”

Industry 4.0 and the smart factories of the future

The news was announced today at Hannover Messe, where the central theme of the 2017 event is Industry 4.0 and factory digitalization.

As reported earlier today by 3D Printing Industry, SAP also launched their Distributed Manufacturing application at the industrial expo. The SAP application, “connects engineering design and procurement teams with 3D printing service providers to optimize design and integrate order creation and procurement.” However, the SAP platform is focused on industrial buyers who do not require the design element and instead need a procurement solution.

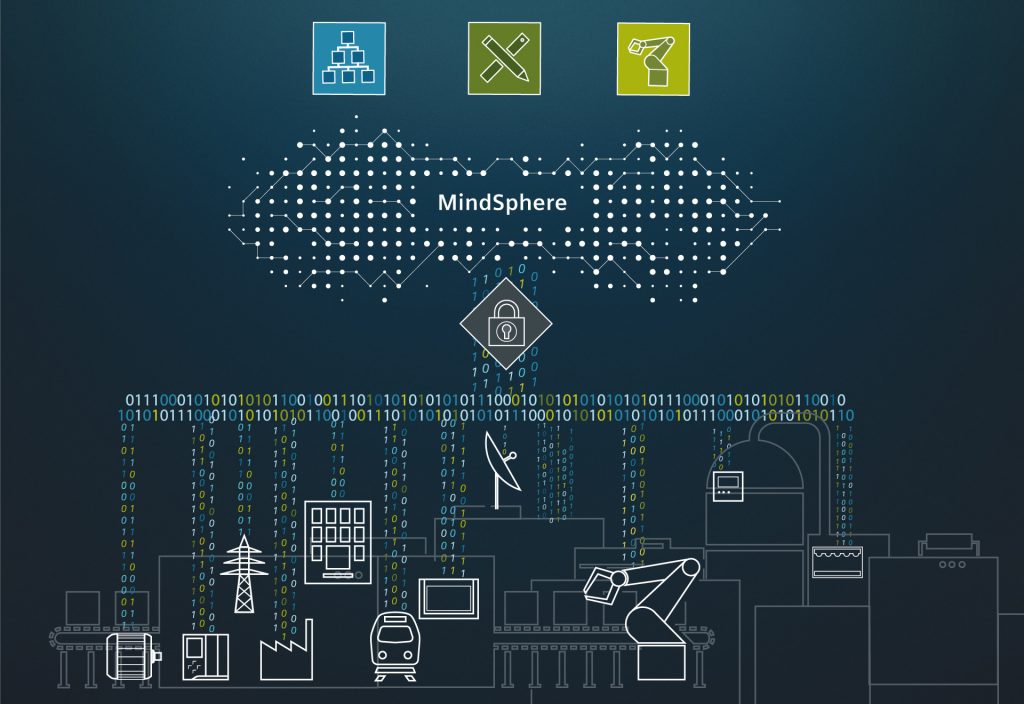

While Both SAP and Siemens offer PLM solutions, of note is also a partnership between the two companies involving MindSphere, an IOT Platform for industrial customers, that was announced in August 2016.

MindSphere is described as the,

First open, industrial IoT operating system to provide plug-and-play connectivity, multiple deployment options with an open interface model and a unique “app-like marketplace” to connect leading Industrial IoT technology providers to enable companies to connect their physical infrastructure to the digital world.

MindSphere is a Siemens product, and built on the SAP HANA Cloud Platform. Theoretically this would mean that if at some later point in time Siemens and SAP were to integrate their additive manufacturing platforms the task would be somewhat easier than if the underlying platforms were separate.

Early access now open

Siemens say that by exchanging information and practical knowledge, “members will have the opportunity to enhance productivity, increase expertise, streamline co-innovation and accelerate the adoption of additive manufacturing technology to a new level of industrial use.”

The new digital platform is expected to launch in mid-2018. Interested participants are invited to contact Siemens about early access.

3D Printing Industry will bring you further updates about developments regarding end-to-end solutions for advanced manufacturing, subscribe to our free newsletter and follow our active social media accounts to be the first with the news.

Also, don’t forget that voting is now open for the 1st Annual 3D Printing Industry Awards, where our readers have nominated the companies leading the 3D Printing Industry. You can make your vote here.

Featured image shows Siemens CEO Joe Kaeser handing over a 3D printed duplicate to Chancellor Angela Merkel during her visit at the Siemens booth with Polish Prime Minister Beata Szydło. Photo via Siemens.