Paris-headquartered 3D printing service bureau Sculpteo has released the seventh edition of its annual international survey, “The State of 3D Printing”.

Intended to provide a comprehensive overview of the additive manufacturing sector, the report suggests 3D printing gained “widespread recognition” as a serious manufacturing technology over the past year, as the industry rose to meet shortfalls in conventional manufacturing resulting from the Covid-19 pandemic. The findings show that despite this shift, investments are down compared to last year, with reliability and materials cited as key to unlocking the potential of the technology going forwards.

With more than 1,900 respondents from 86 different countries, this year’s report is the largest and most internationally representative one yet.

“3D printing has shown its capabilities as a real manufacturing technology through the lens of the Covid-19 pandemic,” said Clément Moreau, CEO and Founder of Sculpteo. “Beyond this support for crippled supply chains which allowed for rapid production of critically needed parts, 3D printing continues to grow its presence in a wide variety of industries and applications.”

Tracking the AM sector’s progress

Sculpteo has been providing 3D printing services through its online platform for over a decade, with locations in Paris and San Francisco and factories across Europe. The platform offers ten 3D printing technologies and more than 75 materials and finishing options, which customers can utilize to manufacture prototypes, individual parts, and serialize the production of components.

Towards the end of 2019, Sculpteo was acquired by BASF, the largest chemical producer in the world, in order to accelerate the production of new 3D printing materials within its Forward AM division. In November last year, the companies launched a new bio-sourced range of Ultrasint Nylon-based 3D printing materials, engineered to bridge the gap between performance and sustainability.

Every year, Sculpteo compiles data about the 3D printing industry to highlight key trends of the sector as it evolves. Last year’s survey identified additive manufacturing’s increasing impact on the industrial manufacturing landscape and a maturing user base. Other organizations also developing reports on the state of 3D printing include Wohlers Associates, which recently published its Wohlers Report 2021.

Of those taking part in Sculpteo’s survey, 66 percent of users have more than three years’ experience using 3D printing, with more than a quarter using the technology daily. Respondents are mainly CEOs, researchers, and R&D team members, and 60 percent have an engineering background. In terms of industries using the technology, the report indicates that industrial goods takes the prime share at 20 percent, followed by service bureau manufacturing (16 percent), and consumer goods (10 percent).

“3D printed parts now present with high-performance properties capable of meeting demands for the toughest applications,” continued Moreau. “This seventh edition of The State of 3D Printing shows once again that the future of 3D printing is bright and those companies that adopt this technology early will see real competitive advantages in the future.”

The State of 3D Printing: Key findings

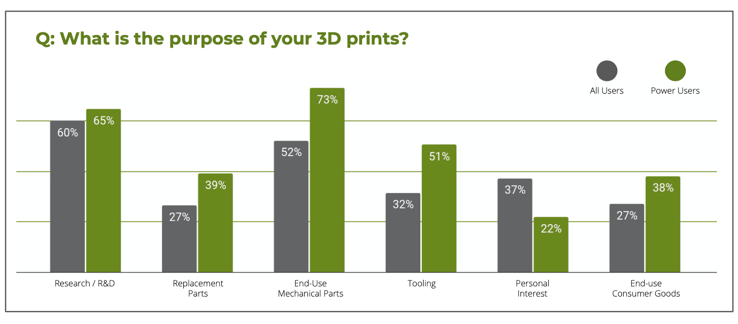

The standout finding of this year’s report is that 3D printing is now considered “as a real production tool” in light of its role plugging supply chain gaps during the pandemic. While still primarily considered for R&D and prototyping applications, the report shows that the technology reaches 49 percent of power users for large series production, and as much as 18 percent for mass production. Additionally, just over half of respondents are using 3D printing for end-use mechanical parts, and 27 percent for end-use consumer goods.

In response to the pandemic, 48 percent of businesses noted an increase in 3D printing operations and have been presented with new market opportunities.

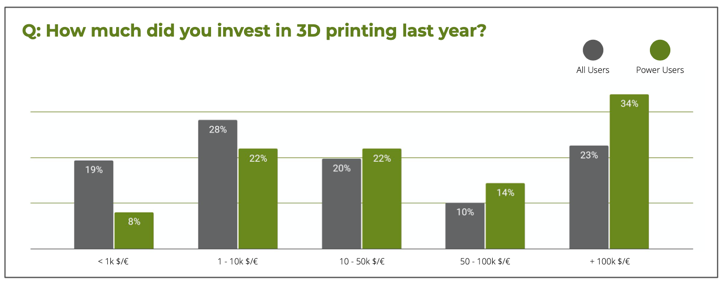

According to the report, this shift towards 3D printing as a “full manufacturing technique” also comes with strong investments. Despite a slight dip since last year as a result of business disruptions, 23 percent of all users and more than a third of power users claim to have invested over 100k in the technology last year.

Confidence has also increased in 3D printing since last year, with seven percent more business users seeing the technology as a “great improvement for the speed of innovation” than last year. Almost two thirds of respondents said they planned to increase their investment in 3D printing throughout 2021, while 70 percent of businesses are looking to find new applications and integrate new materials as the 3D printing market continues to evolve.

Personalization and customization remain key benefits of adopting 3D printing, with one in five 3D printing users that participated in the survey focusing on customized products and limited series. 69 percent of respondents agreed with the advantages of 3D printing over conventional manufacturing processes for complex geometries, while seven percent more participants favored 3D printing for quick iterations than last year.

Mass customization also increased considerably from 32 percent to 41 percent since last year, and Sculpteo predicts this to continue growing within industries such as footwear, sporting goods, and medical applications.

Looking ahead to 2021

The report’s results show the impact 3D printing had on multiple life-saving applications during 2020, and the potential for adoption of the technology to greatly accelerate across a variety of industries as the pandemic recedes. To facilitate this, though, the survey suggests that the industry must lower the cost of entry, offer more reliable technologies, and provide new materials.

For 72 percent of respondents, strength is the most important property of a material, while just over half identified a need for low-cost materials. The study also shows that sustainability continues to gain importance within the industry, with 23 percent of participants selecting this as an important property.

More than half of 3D printing users point to CAD design and testing as the top areas where they spend their time, indicating that training and education for traditional designers through Design for Additive Manufacturing (DfAM) will also help to accelerate the adoption of 3D printing.

The full State of 3D Printing report can be viewed here.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sculpteo package. Photo via Sculpteo.