A team of international researchers is taking a deeper dive into the fundamental physics behind metal 3D printing, all in the hopes of better understanding defects in printed parts.

Since its invention, laser powder bed fusion (LPBF) has proven itself to be an excellent tool for industry, enabling engineers to fabricate complex metal geometries that would otherwise be impossible. However, the process isn’t perfect as the heat generated by the high-power laser beams can often result in pores being formed in components. These defects are detrimental to the density of a part and lead to overall poor mechanical properties in a structure.

In critical industries where part performance is paramount, pores can pose a limitation on the types of parts that can be printed. As such, there’s an ongoing need to develop better defect detection and mitigation techniques in 3D printing.

Using advanced imaging tech, the team comprising scientists from Heriot-Watt University, Carnegie-Mellon University, and Argonne National Laboratory has now examined the material states present during metal 3D printing. The work offers new insights into how and why defects form.

Dr. Ioannis Bitharas, a research associate at Heriot-Watt’s Institute of Photonics and Quantum Sciences, explains, “Our research visualizes the interplay between all states of matter present when a laser interacts with metallic particles.”

How are pores formed in LPBF?

During the metal additive manufacturing process, a laser beam is applied to a bed of powder material. This results in a small pool of molten metal called the melt pool where the powder particles fuse together.

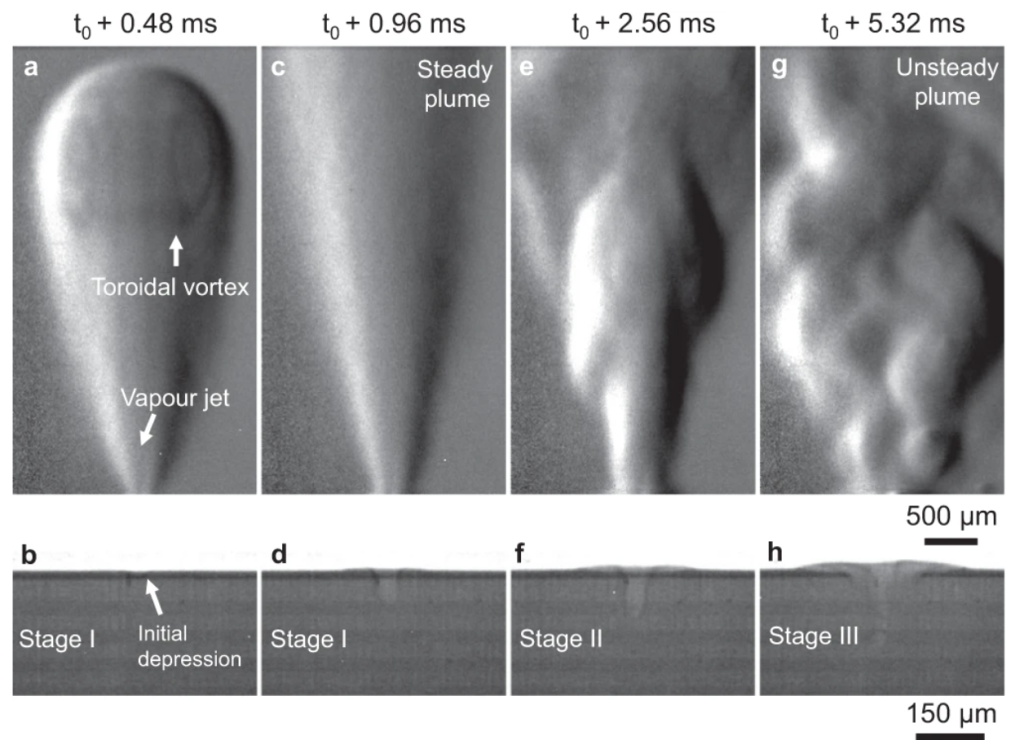

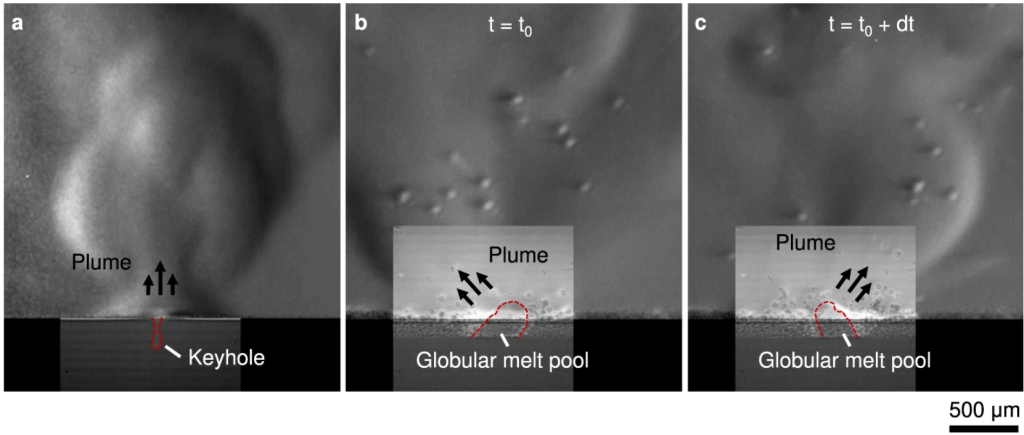

Inside the melt pool, a small amount of metal evaporates and presses against the liquid, which creates a cavity right at the center of the pool. Named a ‘keyhole’, this cavity can collapse on itself if it becomes unstable, leading to the formation of a pore in the 3D printed part.

Additionally, in the event of a collapse, vapor is shot upwards out of the keyhole and forms a plume. This can impact some of the unfused particles in the powder bed, potentially disturbing the top layer of material.

Bitharas adds, “Such events create tiny imperfections scattered throughout the component and, consequently, an unacceptable level of material porosity to many manufacturers. The images we have captured provide, for the first time, a complete picture of such interactions and we can now tell with certainty what is happening.”

Combining X-ray and schlieren imaging

The team used a combination of X-ray and schlieren imaging to examine and characterize the interactions between the gas, vapor, liquid, and solid phases present in a melt pool.

Analyzing the images, they found that the vapor plume’s behavior had a direct impact on the overall stability of the melt pool’s keyhole. Specifically, the more dynamic and active the plume, the less stable the keyhole was, leading to more porosity.

By modifying some of the parameters of the laser such as power, spot size, and scan speed, Bitharas’ team also found that they could adequately control the dynamism of the plume and stability of the melt pool. The researchers believe they’re the first to use the keyhole plume as a process signature that can be monitored, and expect their findings to have major implications in sectors such as aerospace, automotive, and defense.

Professor Andrew Moore, co-author of the study, adds, “Research has so far focused on detecting and predicting defects based on the behavior of the liquid metal or particles, often overlooking the effects of the vapor jet and plume generated above the melt pool. We believe that this work will enable the creation of improved process monitoring and analytic tools that identify and prevent defects in the additive manufacturing of metals.”

Further details of the study can be found in the paper titled ‘The interplay between vapor, liquid, and solid phases in laser powder bed fusion’.

Although important, defect prevention is just one area of metal additive manufacturing research. Just recently, researchers from Tsinghua University and the National University of Singapore investigated the effects of fluid flow on the mechanical properties of metal 3D printed parts. Carefully controlling the formation of new grains and dendrites in printed parts is crucial for tuning the final grain structure, but the effects of fluid flow in the melt pool hadn’t yet been explored until now.

Elsewhere, at the Tallinn University of Technology and the Estonian University of Life Sciences, engineers are looking into how 3D printing can be used to produce soft magnetic cores. Printing magnetic cores has been a major challenge so far as it’s so difficult to preserve core efficiency, but the team has now proposed a laser-based additive manufacturing workflow that they claim can yield superior magnetic properties to soft magnetic composites.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a time evolution of a plume shooting out of a melt pool’s keyhole. Image via Heriot-Watt University.