Swedish multinational engineering firm Sandvik has announced the development of a novel 3D printable cemented carbide.

Previously only used in manufacturing via other technologies, the material features a uniquely tough cobalt and tungsten carbide matrix structure, that lends it the durability needed to yield parts with properties suited to demanding applications.

Using an in-house developed process, Sandvik says it has now come up with a new cemented carbide powder, which can more rapidly be 3D printed into objects that last “up to 20 times longer” than those produced from other steels or alloys.

“Our powders are optimized to print components that look great, work well – and are fit for use in actual applications, demanding environments and serial production,” explains Anders Ohlsson, Lead Product Manager at Sandvik Additive Manufacturing. “It’s also well worth mentioning the ability to 3D print cemented carbide speeds up our time-to-market rather dramatically. Prototyping used to take 6-12 months – and now our lead time to date is a matter of weeks.”

“Sandvik has developed both a powder and a process that are unique.”

Sandvik’s 3D printing portfolio

While Sandvik’s operations cover the metal cutting, digital manufacturing, mining and construction industries, its 3D printing operations generally focus on the development of powders, as well as its consultancy and manufacturing services.

On the material front, the firm has spent over fifteen years establishing a broad portfolio of Osprey 3D printing alloys. Produced in-house at one of Sandvik’s gas atomization towers, these powders can be customized to fit any printing technique, with particles varying from 5 to 500 microns in size. Available in batches of anything from 1 to 6,000-kilos, the company’s Osprey metal range now extends from steels to nickel-based superalloys, enabling them to address a variety of applications.

One way that the materials have been applied recently, is as part of GE Additive’s Binder Jet Beta Partner Program. Following a strategic partnership agreed in late-2020, Sandvik has used its Osprey powders to supply GE Additive’s H2 Binder Jet 3D printer testing regime, in exchange for being able to use the machine itself for production purposes.

Since acquiring a stake in BEAMIT a year earlier, the company has also sought to stretch the limits of its additive manufacturing capabilities. Working with its part-subsidiary, for example, Sandvik has now developed the ability to 3D print super-duplex stainless steel parts, and more recently, it has begun trialing 3D printing in Boliden’s mines, as a means of improving the performance of drill rig parts.

Introducing a new cemented carbide

Thanks to their unique composite structure, in which a wear-resistant phase is bonded together by a ductile metal binder, cemented carbides have the strength needed to yield parts with metal cutting, agriculture, food and oil & gas applications.

That being said, due to their innate hardness, cemented carbides can be challenging to machine, especially into components with complex geometries. Having worked with such materials since 1932, Sandvik has therefore utilized its expertise to develop a means of overcoming this, in the shape of a new powder with “superior wear-resistant properties.”

Developed via an undisclosed ‘patented process,’ this powder is said to enable the production of the same ultra-robust parts as before, while also harnessing the reduced wastage and increased design freedom that comes with 3D printing.

“When implementing additive manufacturing into your business, you basically eliminate all previous design restrictions – enabling you to focus on designing components based on operational needs and requirements, without having to adapt to a specific shape or form,” adds Ohlsson. “Cemented carbide is one of the very hardest, if not the hardest material available in 3D printed shape as of today.”

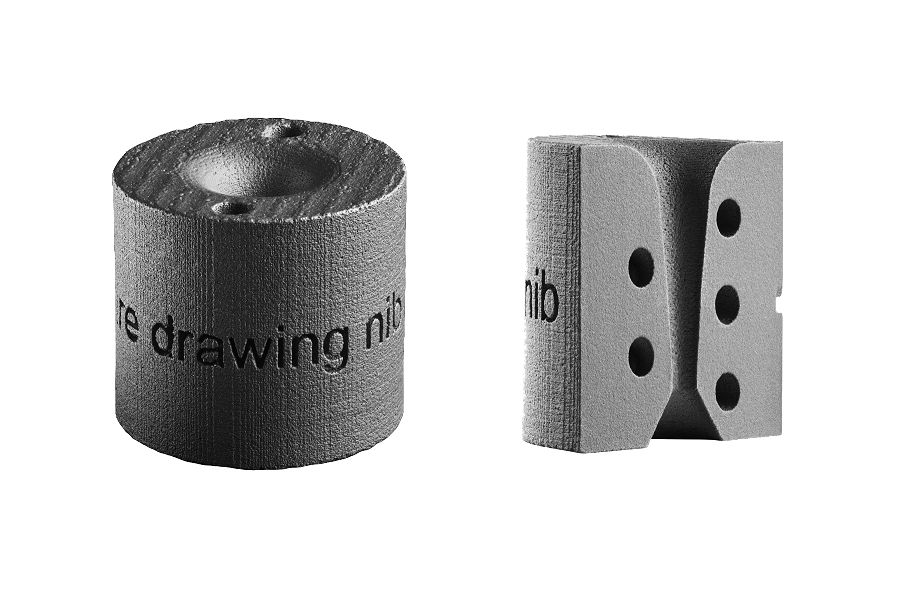

To demonstrate the potential applications of its new powder, Sandvik 3D printed it into a wire drawing nib as part of a recent R&D project. According to the firm, this part featured closed loop spiral coolant channels, enabling it to achieve efficient cooling while keeping its wire dry, something that’d be “impossible to achieve without additive manufacturing.”

Moving forwards, Sandvik believes the “extreme durability” of the material will now make it well-suited to the needs of “industries looking to optimize production efficiency,” particularly those which “operate in challenging environments.”

“Thanks to our longstanding experience in materials technology paired with our expertise along the additive value chain, we can innovate at a speed few others can,” concludes Mikael Schuisky, PhD, a Business Unit Manager at Sandvik Additive Manufacturing. “This makes us uniquely positioned to drive the shift toward the industrialization of 3D printing, and prove sustainable manufacturing isn’t just possible – it’s already happening.”

“3D printing in cemented carbide is a natural next step for us having perfected these materials for decades.”

Advances in high-strength materials

Though Sandvik’s cemented carbide breakthrough is no doubt impressive, it’s far from the first to begin investigating the material’s 3D printing potential. In fact, as long ago as 2019, VBN Components’ cemented carbide Vibenite 480 material won the MM Maschinenmarkt’s additive manufacturing innovation award.

Elsewhere, a number of other ‘superalloys’ have also been developed, specifically with the additive manufacturing of high-strength components in mind. Early last year, researchers at UC Santa Barbara and Oak Ridge National Laboratory revealed that they’d come up with a new defect-resistant 3D printing superalloy, capable of overcoming the cracking issues often seen in high-temp PBF-produced parts.

Similarly, Rosswag Engineering qualified its nickel-based Waspaloy some time ago, a material said to possess excellent corrosion and oxidation resistance. During the company’s initial testing, Waspaloy showed a tensile strength of 1403 MPa and elongation at break of 21%, lending it superior properties to metals such as Inconel 718, which are often used to address demanding aerospace applications.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a handful of parts 3D printed from Sandvik’s cemented carbide. Photo via Sandvik.