Swedish global engineering group Sandvik has acquired a significant stake in Italian metal 3D printing service provider Beam IT. Offering DMLS, SLM, SLS and EBM this company, headquartered in Parma, has been selected by Sandvik as part of a strategic expansion of its metal additive manufacturing portfolio. Kristian Egeberg, President of Sandvik, comments, “The AM sector is developing fast and there is a need for AM-specialist-partners with the advanced skills and resources required to help industrial customers develop and launch their AM programs.”

Other recent metal additive deals from the company have included partnerships with leading 3D printing machine providers ExOne and Renishaw. Egeberg adds, “With the investment in Beam IT we provide our customers with the opportunity to access the complementary and combined power of Sandvik and Beam IT.”

Strategy for the future of AM

Beam IT was founded as a rapid prototyping service in 1997. Since then, the company has stayed ahead of developing market trends and re-positioned its expertise as a specialist in metal additive manufacturing. At present, its production capacity houses 20 PBF machines, and employs 38 people on-site. It also has AS9100 certification and NADCAP approval for aerospace production.

The decision by Beam IT to sell a significant stake in the company to Sandvik has been a strategic move to prepare for the future of AM. Mauro Antolotti, Chairman and founder of Beam IT, comments, “The demand for additively manufactured components is expected to grow rapidly the coming years. In Sandvik, we have a very good owner who can help us accelerate the growth – and who can provide us with leading materials expertise, development of high-quality metal powder suited for all AM processes, as well as world-leading post-processing know-how.”

Though parties have agreed not to disclose the purchase price of this segment of the company, the “significant stake” held by Sandvik has the right to be increased over time.

Sandvik additive manufacturing

In addition this this recent deal, and other partnerships within the industry, Sandvik has made sizeable investments into many areas of metal AM including binder jet technology. In 2018 Sandvik the company also allocated $25 million to establish a new production facility for metal additive manufacturing powders, set to open in 2020.

In a recent demonstration of its capabilities, Sandvik produced a fully 3D printed smash-proof guitar, which was put to the test by heavy metal guitarist Yngwie Malmsteen. The company has also launched its own 3D printable diamond composite material.

Speaking of the most recent deal Michele Antolotti, President of Beam IT, adds, “We are extremely pleased to announce this deal and partnership with Sandvik, which aims to leverage synergies and further strengthen both companies’ position on the metal AM market,”

“Our partnership will definitely benefit both current and future AM-customers going forward.”

For all of the latest additive manufacturing business news as it unravels subscribe to our newsletter, follow us on Twitter, and like us on Facebook. Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

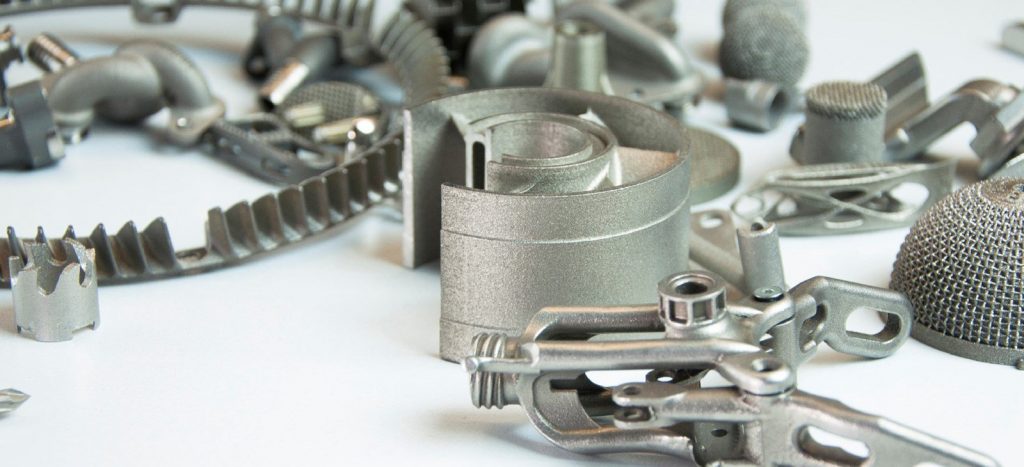

Featured image shows metal 3D printed parts from Beam IT. Photo via Beam IT