3D printing for vintage car restoration? Yep.

UK-based KW Special Projects (KWSP) and its sister company KW Motorsports have teamed up to restore a historic 1927 French sports car to peak condition using additive manufacturing.

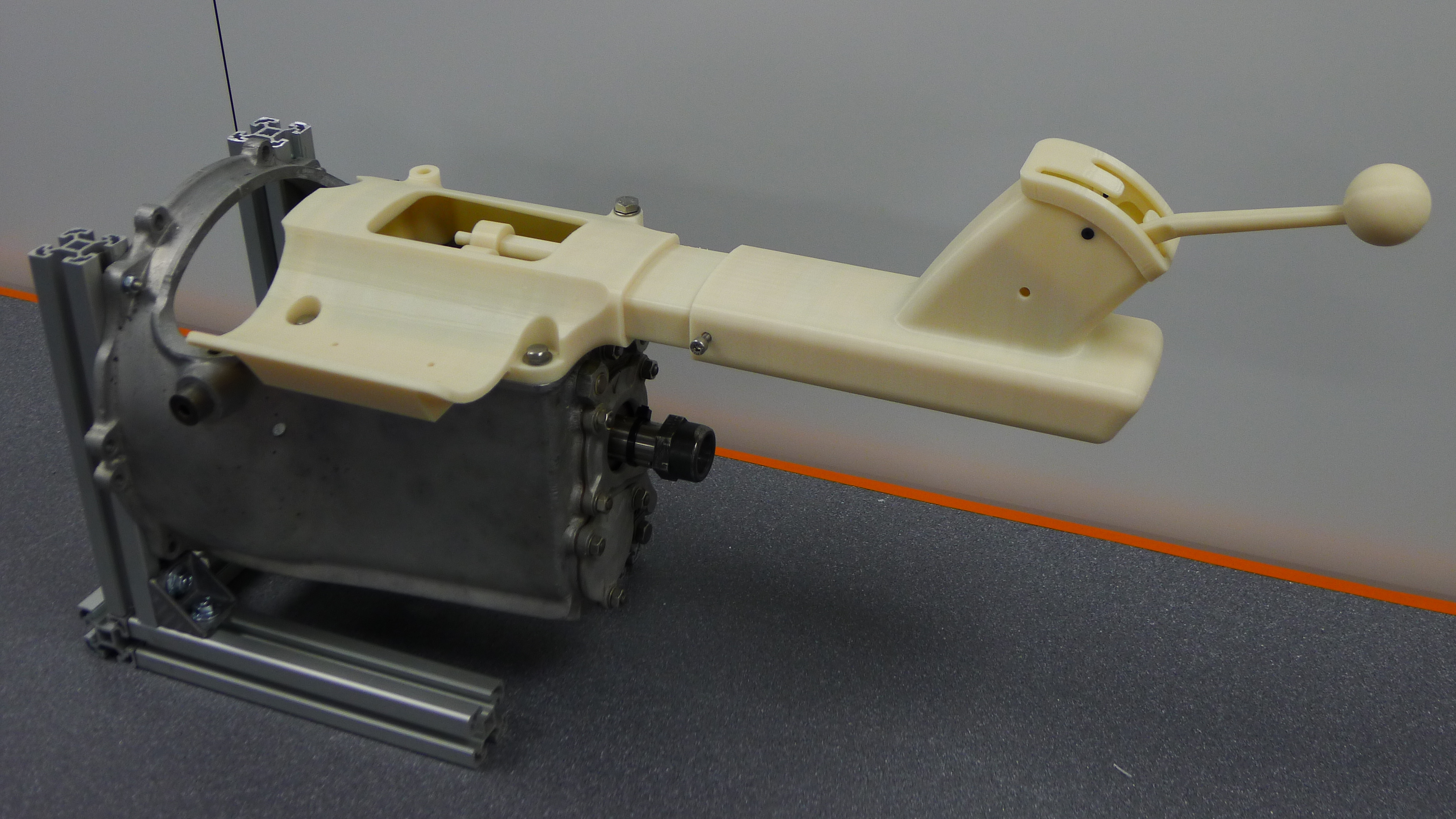

The 1927 Amilcar C6 in question was built with an extended selector housing, an upgrade from the original design of the car, possibly reworked in order to make driving more comfortable for the owner. When the restoration experts at KW Motorsports and KWSP were confronted with only a old black and white photo of a missing gear selector housing, engineers used their engineering expertise and 3D printing systems to design and manufacture the missing parts.

“This was a unique project that demanded not only technical know-how of the latest AM techniques, but also creativity and intuition” , says Kieron Salter, managing director of KWSP.

He continues, “Using Additive Manufacturing instead of conventional manufacturing methods, our engineers were able to design and make parts quickly and cost effectively using 3D printing technology. This approach enabled us to fit a printed prototype into the actual vehicle to ensure it met with the design brief, fitted perfectly into the cockpit and also gained the owner’s approval.

Using Solidworks CAD software, we converted the scan data into useful CAD files that gave us the mechanical interfaces and geometry to begin designing the new cover. Because the original castings were manufactured from handmade patterns, there are not many exact features within the cover that can be predicted. Also, the new ergonomic position of the gearshift via the remote linkage was not easy to predict, so we not only had to reverse engineer the casing, but also its installation in the car and the hard objects such as the dash bulkhead and steering wheel in order to get the positioning correct.”

The combination of technologies used to print these parts involved not only 3D printing but also an innovative use of aluminum casting and CAD design. Without the flexibility of 3D printing technology and design these parts would likely have been too costly and complex to attempt. This unique effort is an excellent example of the use of creative technological solutions to restore, reproduce or repair valued objects from our past.