A team of Chinese and Taiwanese researchers from such institutes as Zhejiang University (ZJU), Taipei Medical University, and National Central University (NCU) have used Aerosol Jet Printing (AJP) to develop 3D nanostructural coatings that enhance signaling in 3D printed neurological devices.

The research paper, published in Advanced Materials explains, “Over the past two decades, prosthetic devices have been successfully applied to treat neurodegenerative disease. However, the long-term utilization is limited by adverse biological reactions in host tissues, resulting in signal failure of the implanted devices.”

“It is more important to design biocompatible coatings for the implanted devices to mimic mechanical and structural properties of brain tissues in order to reduce inevitable tissue responses for long-term utilization.”

Aerosol Jet Printing and neural implants

The AJP process involves spraying metal-based inks onto existing 2D and 3D substrates, creating emulating a multi-layer circuit board interconnections. This method also eliminates the need for complex wire bonding conducted within LED chip fabrication.

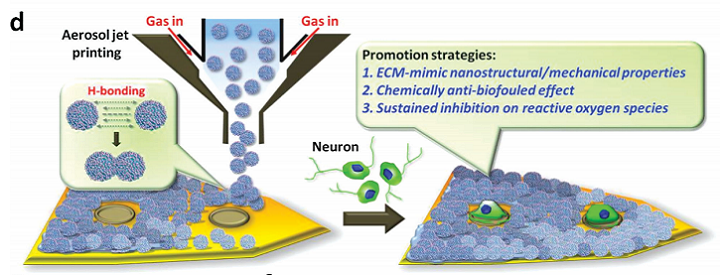

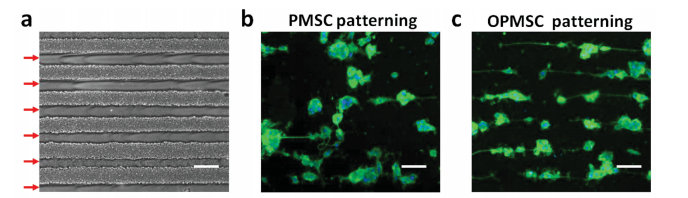

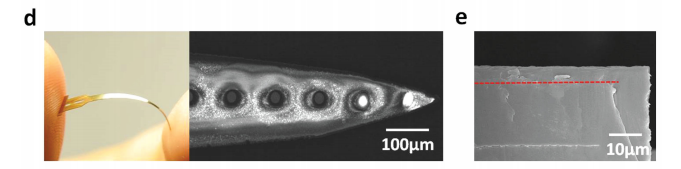

Due to its low-temperature technology and contactless nature, the team used AJP to directly fabricate nanogels onto a membrane of the microscaled patterned polyimide-based neural probe. The nanogels were created by the researchers using a “new type of anti-inflammatory nanogel,” based on the amphiphilic polydimethylsiloxane-modified N, O-carboxylic chitosan (PMSC) incorporated with oligo-proanthocyanidin (OPC), called OPMSC.

The OPMSC nanogels were constructed to mimic the structural and mechanical properties of brain tissue and sustain non-fouling (a surface’s ability to shed potential contamination) for tissue encapsulation.

“With the integration of nanomanufacturing technology and multifunctional nanomaterials into the neural implants, we can extensively reduce the reactive tissue responses, provide continuous protection of surviving neurons, and ensure long-term performance reliability of implants,” the researchers explained.

The research paper, titled “Multifunctional 3D Patternable Drug-Embedded Nanocarrier-Based Interfaces to Enhance Signal Recording and Reduce Neuron Degeneration in Neural Implantation,” is co-authored Wei-Chen Huang, Hsin-Yi Lai, Li-Wei Kuo, Chia-Hsin Liao, Po-Hsieh Chang, Ta-Chung Liu, San-Yuan Chen, and You-Yin Chen.

Stay updated with the latest additive manufacturing news by subscribing to the 3D Printing Industry newsletter. Also, find us on Facebook and like us on Twitter.

Looking for jobs in engineering? Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

Featured image shows the aerosol jet printing process where nanogel suspensions are directly patterned on a neural probe to create an anti-inflammatory neural interface. Image via ZJU/NCU.