New research has been published on an innovative new application of metal additive manufacturing. The study was undertaken by researchers at Peter the Great St. Petersburg University (SPbPU) and Delft University of Technology (TU Delft) to refine the selective laser melting method.

The aim of the research was to create functionally graded Inconel 718. Functionally graded means to combine the desired properties of two materials in order to produce an advanced structure. Functionally graded Inconel has significant application for the aerospace industry for its high strength and heat resistance.

The paper, titled ‘Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties’, has been published in the Materials & Design journal.

Inconel 718 is a Nickel-Chromium ‘superalloy’ and has been the subject of research funded by NASA. The University of Pittsburgh has received $500,000 in funding from the space agency to create a simulation to assess the microstructure of 3D printed Inconel 718.

The need for a new novel technique

According to the paper, while Inconel 718 is a useful material for the creation of strong metal parts, it is difficult to control the performance of the material in the traditional casting or forging processes. Citing the advancement of complex parts in mechanical engines, the paper explains there is a need for a new manufacturing technique.

The researchers state that current additive manufacturing methods create parts that, though perform well, show strong anisotrophy. Anisotrophy refers to the directional dependence of a material, for example carbon fiber is an anisotrophic material as its strength is dependant on the directional alignment of carbon fiber threads. This research aims to address this and create Inconel 718 that has advanced directional microstructure.

For this reason, there has been research into the possibilities of 3D printing carbon fiber by another group of Russian researchers. This research was able to introduce more complex structures to 3D printed carbon fiber.

Creating equiaxial structures

The selective laser melting method of additive manufacturing already has great application for creating complex parts. For example, European conglomerate Siemens has just 3D printed an impeller using selective laser melting for a nuclear power plant in Slovenia.

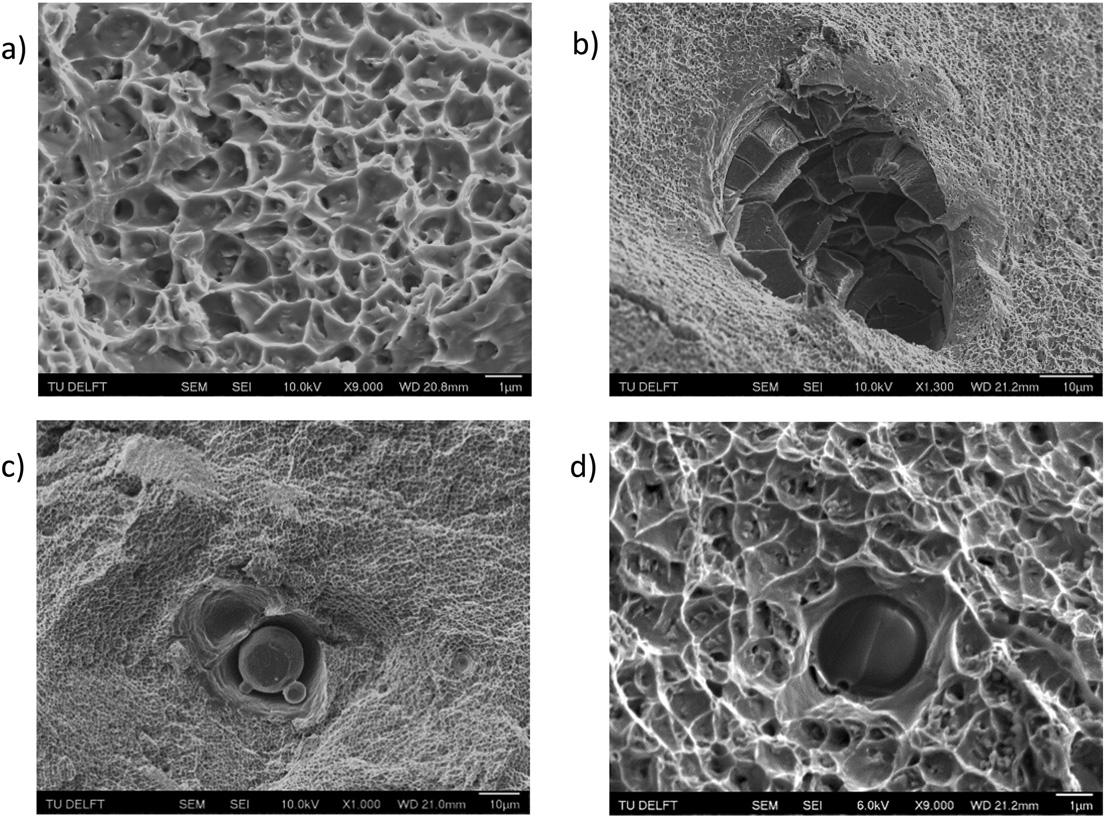

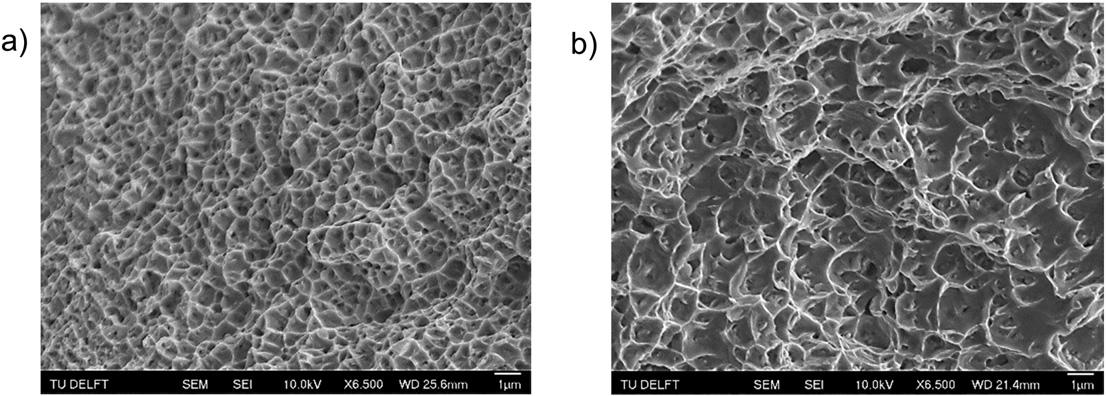

The research paper found that using a lower power source for the selective laser melting process resulted in a better microstructure of the Inconel. This was shown in the paper by comparing SEM images of 250 W laser parts and 950 W laser parts. Figure 13 shows the part created with the higher powered laser (950 W) has many deformities which could affect its strength and performance.

Future applications

Vadim Sufiiarov, assistant professor of “Development, technologies and materials in aircraft engine building” at SPbPU, said

This technology can be used for manufacturing of products operating in extreme conditions, such as high pressure and temperature…Therefore, this development can be applied for manufacturing of gas turbines elements for aviation, energy and marine,

Concluding their paper, the researchers explain that they can now expand this, “developed process strategy…to design functional gradients with selected tailored properties and to account for directional anisotropy of solidified components.”

This research paper was written by V.A. Popovicha, E.V. Borisovb, A.A. Popovichb, V.Sh. Sufiiarovb, D.V. Masaylob, and L. Alzinac.

Vote now in the 1st Annual 3D Printing Industry Awards.

Sign up to the 3D Printing Industry newsletter for the latest news on additive manufacturing research. Also make sure to follow us on twitter and Facebook.

Featured image shows figure 2 of the research paper “3D cube representing front (XZ), side (YZ) and top (XY) microstructure of a) 950 W and b) 250 W processed parts”. Image via Materials & Design.