New research from Purdue University looks at the use of halftoning to improve the surface quality and color of 3D printing. 3D printing in full color is seen by some as one of the final obstacles facing technology. This new paper from Purdue University hopes to improve color capabilities by creating an algorithm that focuses on optimizing individual voxels. The halftoning algorithm is approached in relation to HP’s multi-jet fusion technology.

The ‘3D Halftoning’ research was published in the Electronic Imaging Journal as part of a symposium that took place last week in San Francisco. The journal is co-published by SPIE and IS&T. SPIE is an international non-profit society for optics and photonics. While the Society for Imaging Science and Technology is an international organization that is focused on “the latest scientific and technological developments in the field of imaging“.

The Electronic Imaging symposium ran alongside SPIE’s Photonics West conference which also occurred in San Francisco last week.

3D Halftoning

Halftoning is the representation of an image or object by using small dots which have a gradient of color. It simulates shades of color by varying the size and depth of the dots. This research focuses on approaches to 3D printing that use a voxel-by-voxel technique like HP’s Multi-Jet Fusion technology. By concentrating on the voxels, HP believe they have revolutionized the 3D printing industry. This new algorithm will change the way 3D files are configured for printing in a digital system. Hoping to improve surface quality and color printing based on 2D printing principles of halftoning.

The research paper explains how halftoning can optimize individual voxels,

This technology enables micro manipulation of a single voxel, which can produce much smoother and higher resolution surface with high quality image reproduction. 3D printers equipped with this technology will have more potential in generating high quality and complex appearance 3D objects.

The research aims is to develop a direct binary search (DBS) halftoning algorithm for three-dimensional objects. They believe their research is the first of its kind to implement the DBS algorithm in 3D rather than 2D. The Purdue researchers explain that “by utilizing Multi-Jet technology which enables voxel-wise printing, digital halftoning will be able to play a core role in improving 3D surface reproduction quality.”

Conclusion

It seems this algorithm has been developed by the research team specifically with HP in mind, directly referencing the company and their Multi-Jet fusion technology. Furthermore, the research paper has credited Jan P. Allebach who is Purdue University’s Hewlett-Packard Distinguished Professor of Electrical and Computer Engineering.

As a result of their research, the team at Purdue were able to modify the 2D DBS algorithm for use with 3D printing,

The 3D DBS halftoning algorithm can yield very reasonable and high-quality halftones which is almost the same as 2D DBS does in 2D printing. By only halftone the surface of the object and the use of onsurface look-up table, the computational cost is greatly reduced.

This research may have an impact on 3D printing techniques in the future, with hopes it will greatly improve the surface texture of prints. However, for now this research will likely only affect HP’s 3D printing technologies. Nevertheless it is an interesting approach to use principles used in 2D printing with its three-dimensional counterpart.

The ‘3D Halftoning’ research paper is available here.

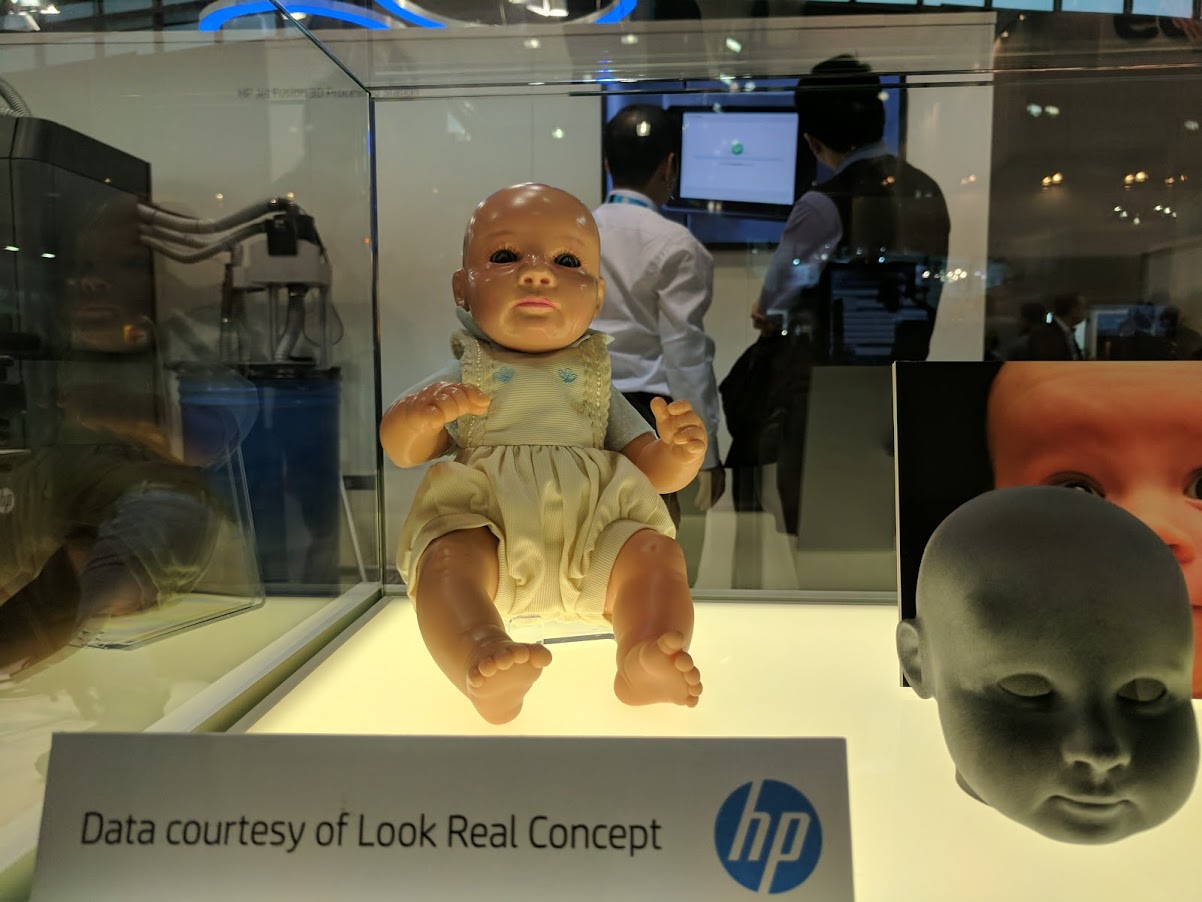

Featured image shows the HP Jet Fusion marketing campaign which has focused heavily. Image via HP.