German 3D printer manufacturer Rapid Shape has launched a new range of DLP 3D printers designed for the jewelry industry. Named the S+ series, the company has developed four 3D printers for the new line: the Studio-Line S20+ and S30+, and the Heavy-Duty-Line S90+ standalone and S90+ cabinet.

These 3D printers have been specifically optimized by Rapid Shape for the production of castable 3D printed parts for jewelry manufacturing. The S20+ and S30+ fall under the company’s Studio-Line of S+ 3D printers, which are intended for easy and fast jewelry manufacturing. On the other hand, the S90+ standalone and S90+ cabinet of the Heavy-Duty-Line are geared towards more continuous use at high speeds, for larger jewelry designs and filigree.

“The new jewelry 3D printers start exactly where the user needs them: we respond to the needs of the industry. Those who want to achieve optimum printing results can do so with the S20+ and S30+ in fine, regular or large versions,” comments Andreas Schultheiss, Managing Director of Rapid Shape.

“Our printers are ideally suited for detailed, filigree and precise surfaces with little post-processing.”

DLP 3D printing specialist

Rapid Shape is a developer of DLP 3D printers specifically for the dental, jewelry, industrial goods, and hearing aid industries. The company is headquartered in the South German town of Heimsheim.

Rapid Shape has developed a patented technology for its DLP 3D printing process known as Force Feedback that uses a measuring device to monitor the separating forces during printing. Ensuring a sensitive separation process, this is said to increase print speed as well as quality, according to the company.

In 2018, Rapid Shape announced a new range of 3D printers for the hearing aid industry, comprising the Studio-Line HA20 II, HA30 II, and HA40 II systems. For prototypes and small batch production, the company provides its 130+ and 140+ 3D printers. The 130+, for example, is designed to be fast, flexible and semi-automatic with a 151 x 85 mm build area and 1920 x 1080 projector resolution. Rapid Shape has developed a large portfolio of 3D printers for the dental sector as well, which includes solutions for dentists, small and large dental labs, and fully automated production systems.

Recently, Rapid Shape announced it had expanded its partnership with global chemical company Henkel, in order to create applications for Rapid Shapes’ DLP 3D printing technology using Henkel’s material expertise. Rapid Shape is now a member of Henkel’s open material platform, where the company will be able to certify Henkel’s materials for use on its open 3D printers.

The S+ series 3D printers

Both the S20+ and S30+ 3D printers in the Studio-Line can be purchased with three different building area sizes: the S20+/S30+ fine (84 x 47 mm), the S20+/S30+ regular (101 x 57 mm), and the S20+/S30+ large (133 x 75 mm). Each of the S20+ and S30+ 3D printers is able to 3D print with a 1920 x 180 px resolution, using a 405 nm UV LED light source.

The S20+ 3D printer is equipped with the most basic features in S+ series to enable the production of jewelry. Its key features include a resing handling system (RHS) and Certified auto calibration (ACCS) technology. It also comes equipped with LCD display touch screen This particular machine is intended for casting shops, design offices, and jewelry manufacturers. Force Feedback technology on the S20+ is optional, whereas on the S30+ the patented process comes fully integrated within the system. Additional benefits of the S30+ include a resin mixing system, resin temperature control and optional automatic separation module (ASM), eliminating the manual steps required to remove parts from the build platform. The module collects print jobs in an integrated catch tank.

Moving on to the Heavy-Duty-Line of 3D printers in the S+ series, the S90+ Standalone is able to 3D print in 2560 × 1520 px, a higher resolution compared to the Studio-Line systems. It also features a much larger build volume, measuring at 232 x 137 mm. To enable 24/7 continuous production, it also comes equipped with an AC controlled printing interior, a dual-circuit cooling system and a heat exchanger. Additionally, the system comes integrated with Force Feedback technology. It is aimed at companies looking to create a production line for jewelry manufacturing.

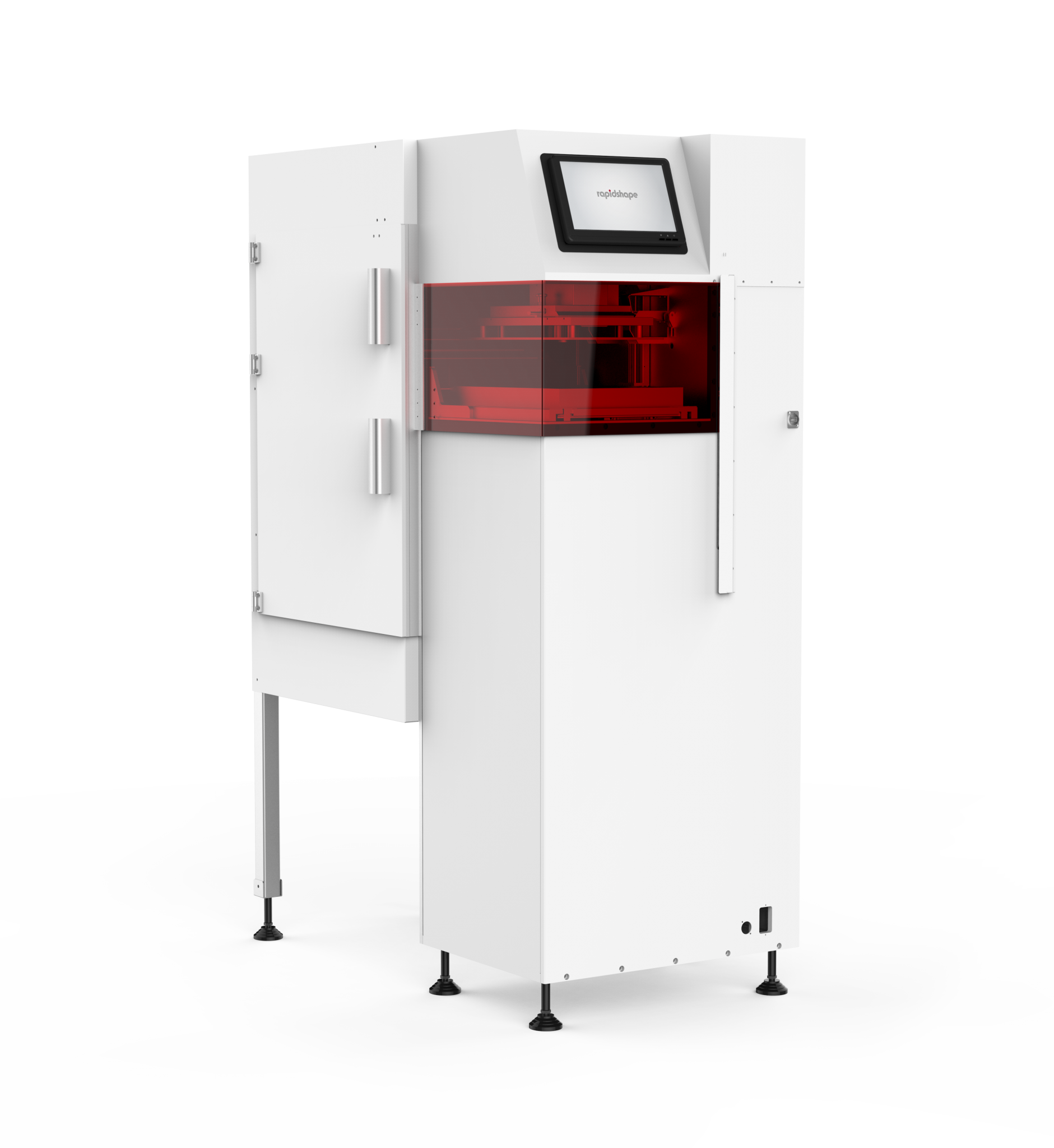

The S90+ Cabinet has the same specifications but is also equipped with an additional ASM module, allowing users to combine its continuous 3D printing capabilities with automated post-processing. Additional options for the S90+ cabinet are an automatic resin refill system and the choice of receiving the 3D printer with a cabinet or conveyor belt.

Technical specifications

Below you will find the technical specifications for each 3D printer in the S+ series. For pricing, customers should contact Rapid Shape for information about pricing.

| Specifications | S20+ fine | S20+ regular | S20+ large |

| Building area | 84 × 47 mm | 101 × 57 mm | 133 × 75 mm |

| Native pixel | +/– 21.5 µm | +/– 26 µm | +/– 34.5 µm |

| Max. part height | – | 90 mm | – |

| Light source | – | 405 nm UV LED | – |

| Resolution | – | HD 1920 × 1080 px | – |

| Dimension (W × H × D) | – | 335 × 541 × 349 mm | – |

| Connections | – | WLAN, TCO/IC, USB | – |

| Control | – | 7″ LCD-Display, touch control | – |

| S30+ fine | S30+ regular | S30+ large | |

| Building area | 84 × 47 mm | 101 × 57 mm | 133 × 75 mm |

| Native pixel | +/– 21.5 µm | +/– 26 µm | +/– 34.5 µm |

| Max. part height | – | 110 mm | – |

| Light source | – | 405 nm UV LED | – |

| Resolution | – | HD 1920 × 1080 px | – |

| Dimension (W × H × D) | – | 335 × 541 × 349 mm | – |

| Connections | – | WLAN, TCO/IC, USB | – |

| Control | – | 7″ LCD-Display, touch control | – |

| Specifications | S90+ Standalone | S90+ Cabinet |

| Building area | 231.5 × 137.3 mm | – |

| Native pixel | +/- 22.5 µm | – |

| Max. part height | 150 mm | – |

| Light source | 405 nm, ultra high power UV LED |

–

|

| Resolution | 2560 × 1520 px | – |

| Dimension (W × H × D) | 443 × 1593 x 625 mm | 625 × 1593 × 800 mm |

| Connections | TCP/IP, USB | – |

| Control | 10″ LCD-Display, touch control | – |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the entire line of jewelry 3D printers in the S+ series. Photo via Rapid Shape.