German 3D printer manufacturer Rapid Shape has announced it has expanded its partnership with global chemical company Henkel. The partners aim to develop Henkel’s material expertise for Rapid Shapes’ DLP 3D printing technology, in order to create novel 3D printing applications.

As part of the extended partnership, Rapid Shape is now a member of Henkel’s open material platform, where the company will be able to certify Henkel’s materials for use on its open 3D printers. Henkel will implement Rapid Shapes’ DLP systems within its 3D printing ecosystem, leveraging the technology to serve its broad customer base.

Both Rapid Shape and Henkel are presenting its 3D printed demo parts at Formnext 2019 this week. Visit Rapid Shape at Booth A11 in Hall 11.1, or find Henkel at Booth C41, Hall 12.1.

“We aim to further expand our open materials approach and are excited to welcome Rapid Shape as a technology partner for our high-performance materials,” explained Philipp Loosen, Head of 3D Printing at Henkel.

“Together we aim to further develop, evaluate and drive 3D printing solutions tailor-made for applications in the mass production of additive manufacturing across industries.”

Developing high-performance DLP materials

Headquartered in the South German town of Heimsheim, Rapid Shape develops DLP 3D printers specifically for the dental, jewelry, industrial goods, and hearing aid industries. Rapid Shapes’ technology is based on a patented Force Feedback DLP 3D printing method that uses a measuring device to monitor the separating forces during printing, ensuring a sensitive separation process. This is intended to increase print speed as well as quality.

Rapid Shapes’ systems include the 130+, a DLP 3D printer designed to be fast, flexible and semi-automatic with a 151 x 85 mm build area and 1920 x 1080 projector resolution. The company also announced a new range of 3D printers for the hearing aid industry in 2018, comprising the Studio-Line HA20 II, HA30 II and HA40 II systems.

Rapid Shapes’ collaboration with Henkel is intended to develop high-performing materials for its DLP technology. Thus far, both companies have already tested some of Henkel’s materials on Rapid Shapes’ 130+ 3D printer, including the Loctite 3D 3820 ultra-clear resin. This material will give customers in the health industries access to 3D printed, transparent, high-performance parts for use in visual flow inspection, covers and lenses. Both Henkel and Rapid Shapes are also part of the SYMPA R&D consortium seeking to advance new materials and stereolithography (SLA) processes for the automotive sector.

“The continuing development of materials and printers has opened the door for new opportunities across industries. By collaborating with Henkel, we believe that we can create significant value for customers searching for a high-performance combination of material and machine solutions,” added Andreas Schultheiss, CEO of Rapid Shape.

3D printing updates from Henkel

This is the latest in a line of updates from Henkel, as it continues to expand its partnerships and foothold within the 3D printing industry. Last week, the company developed a new fire-resistant photopolymer in partnership with Californian 3D printing startup Origin. The photopolymer is compatible with the Origin One, and is a product of a partnership between the two parties signed in February this year.

In the same week, Henkel also entered into a partnership with the New York-headquartered 3D printing marketplace and service bureau Shapeways. As well as offering customers on-demand 3D printing services with Loctite materials, the partners also aim to expand Henkel’s material provisions for large-scale additive manufacturing.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

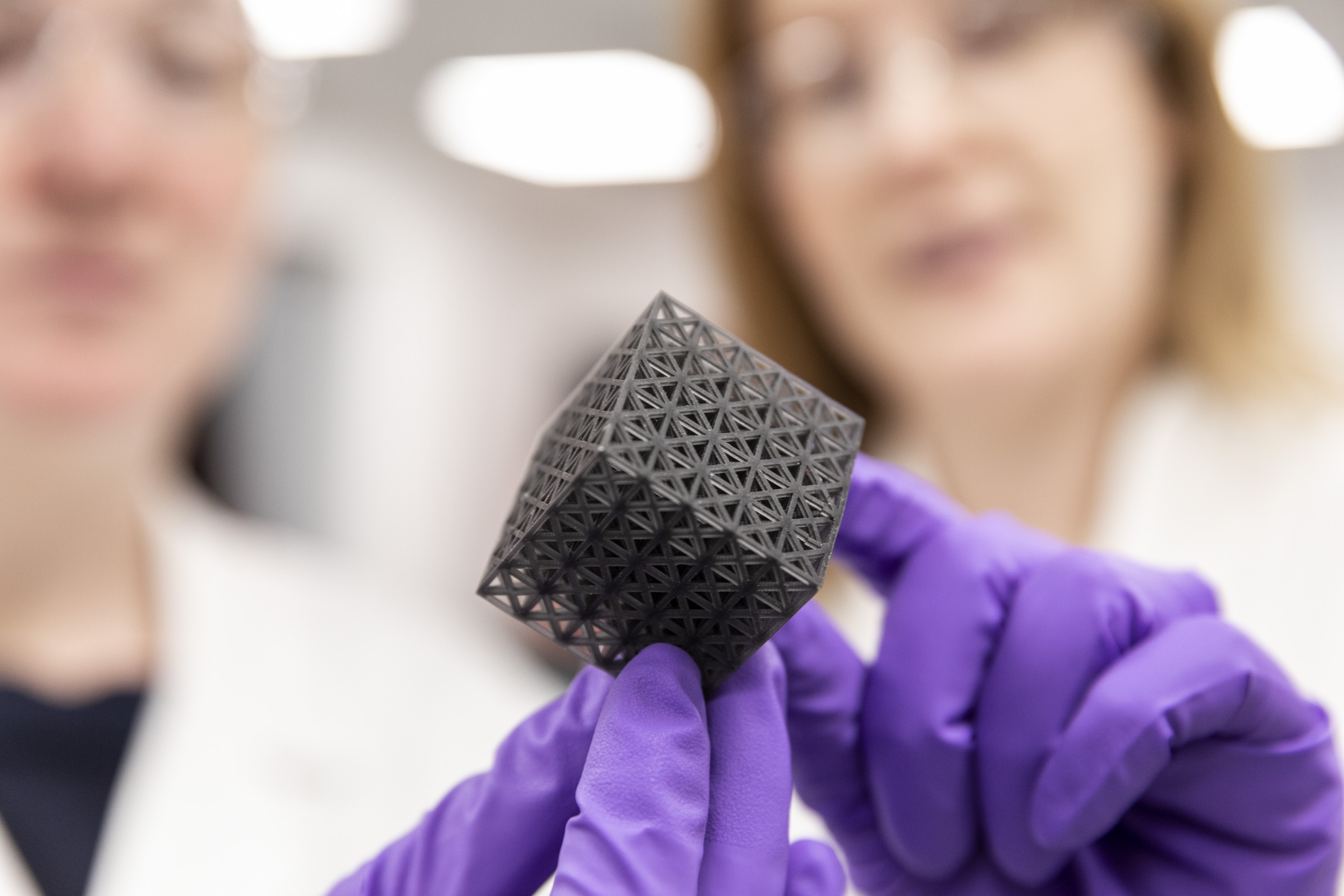

Featured image shows Henkel and Rapid Shape collaborating for novel 3D printing solutions with a focus on the mass production of functional parts. Photo via Henkel.