It’s always lovely when the first face is a friendly face, and I totally lucked-out, bumping into Richard Horne at reception. Nattering away about the exciting day stretching out ahead we made our way through to the open, triple-floored exhibition space that creatively brought all of the different facets of the 3D Printshow together. Maintaining the wonderful vibe that Kerry Hogarth and her Team Awesome initiated last year, this venue was a huge improvement and so much more practical.

Through the doors and the first mega exhibit to greet visitors was the phenomenal work of Jason Lopes of Legacy Effects. Jason was a presenter last year and returned with a super-scaled-up exhibit that properly demonstrates his capabilities with 3D printing. I am so in awe of what he does with this tech, phenomenal doesn’t really do it justice. This year he had support — in every way. Rob Ramsdell works with Jason and he is the guy responsible for taking the 3D printed parts, and, with some serious post-processing and finishing skills, makes them look like this:

[nggallery id=118]Another cool guy from LA in my contact network. And like Jason great company. Lucky me.

Before the crowds started pouring in, I was lucky enough to do a quick scouting exercise to see what & who was there before jumping in to the more detailed chats. What struck me most was the number of new entry-level machines that hadn’t even made it onto my radar — most notably BEEVERYCREATIVE (Portugal), bq witbox (Spain), Cartesio3D (The Netherlands), and WASP (Italy). There was also Omni3D (Poland), but I had had a heads up to look out for this one last week. Individual posts, with specs, will follow on these.

But a couple of images won’t go amiss:

[nggallery id=117]

Caught up with the guys from Fuel3D — the mega successfully funded, low cost and easy to use 3D scanner. They had the first working prototypes of the scanner on show, and quite simply, it does exactly what it says on the tin! It’s so easy to use, even I could do it and not cock it up, and the 3D data produced (they where scanning anyone that wanted to be scanned and sending them the files) looked pretty good to me, with simple .stl conversion commands. They’re currently in the process of fulfilling the Kickstarter pledges and looking to be shipping them Q2 next year.

Stopped by to see the lovely ladies and Dr Connor McCormack of Mcor and had a bit of a gossip, nothing that can really be repeated here. Also caught up with Gary Miller of IPF who introduced me to a very talented Zbrush designer, Alex Down. His work is truly exceptional with a keen understanding of designing specifically and very effectively for 3D printing processes. It was also delightful to shake hands with Brook Drumm of Printrbot. A lovely man and so very passionate about what he is doing.

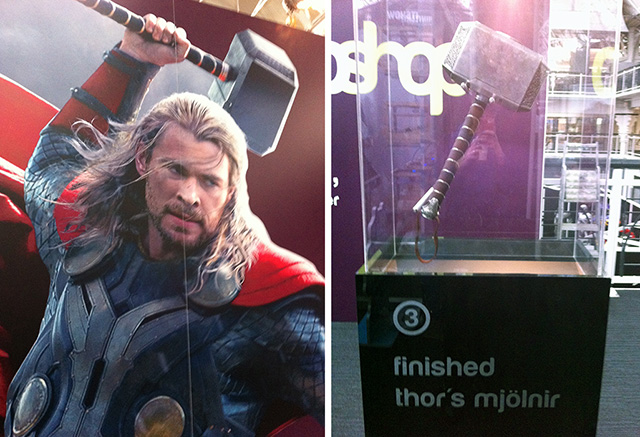

I also stopped by to see Amanda Darby who now works for Propshop. Amanda is another extremely talented user of 3D printing technology with an in-depth understanding that allows her to maximize the potential of the tech to huge effect. She was the lady (freelance at the time) behind all the models for the Pirate Movie. Now at Propshop, a London based company with a similar remit to Legacy Effects, the company is contributing to some of the latest Hollywood blockbusters and 3D printing is key. The latest prop is Thor’s hammer, produced by Jet Cooper on a voxeljet 3D printer, of which the company has three.

So, if you read my reviews regularly, you know there is always at least one moment when my jaw drops, right? Well, on this occasion it was when I first spied the work of Crea’Zaurus 3D. Oh my word — these were life-size 3D printed models of dinosaurs (the clue is in the company name). But this work is extraordinary. The company provides a range of services for the paleontological and museum sectors, and 3D printing is an increasingly useful tool for them. Talking to Lucovic Blein and Cyrielle Langiaux who are based in France, the passion typical of people working with 3D printing technologies was wholly evident. They have two Objet 3D printers in-house. I had made a note to find them ahead of the show, and have a 3DPI writer on the case for a more in-depth article about this application, but nothing quite prepared me for coming face to face with the dinosaurs.

Crea’Zaurus3D were just by the Stilnest exhibit. So that was my next port of call. I had been anticipating the Cuckoo clock with glee. I was to be somewhat disappointed because, in true product development style, the process had gone slightly awry at the 11th hour. The clock was not there on the opening day of the show — it was on its way. Nothwithstanding, Julian Leitloff, the charming CEO of Stilnest, soon reformed my smile when he introduced me to the company’s range of jewellery. Working with a number of designers and a range of materials, the line is really rather beautiful. My favourite was the ‘Through Hole’ ring by designer Colin Butgereit. It’s the one on the left below.

I stopped by to catch up with the inimitable Phil Reeves, between his presentations at the show, who I had worked with recently on the 3D Printing & Healthcare Industry Report. Always a pleasure, always find out something new and always have a laugh. The guys from the Uni of Nottingham were also nearby, with Professors Hague and Dickens on hand for a quick chat. They were accompanied by Associate Professor, Chris Tuck, who at the bar later in the evening hinted at some news on the metal front heading my way. As well as something even bigger, but he can’t talk about that …… yet! Frustrating but typical of this industry over the years, some things will NEVER change!

Caught up with a few people on the fly, so to speak. Richard Bendall from Renishaw, like his colleague Jeremy Pullin (not present), pulls no punches and never EVER takes any prisoners. So much fun to speak to, but I probably shouldn’t quote him verbatim. Martin Stevens and Trupti Patel of ‘It is 3D’ are always a delight to talk to. These guys are working on an interesting project with Techopop for next year — an 8-week Pop-up Festival of Science, Technology, Design and Innovation.

Similarly Frank Cooper and Gay Penfold of the Jewellery Industry Innovation Centre (JIIC) in Birmingham. With a big TSB project initiated they are being kept firmly on their toes with exciting applications developing and emerging in jewellery all of the time. They work with some extremely talented jewellery designers and they introduced me to one, Jessica Noble. Jessica has developed her own line of jewellery in keeping with her long-time vision and is only now looking at 3D printing as a fulfillment manufacturing process. I found this quite a novel message actually, as many up-and-coming jewellery designers are designing for 3D printing, to show off the complex geometries and forms it can create.

I tried to stop by the 3Doodler space numerous time on Thursday — they had two tables set up with working 3Doodlers for visitors to play with. They were constantly swamped by kids and adults alike all trying them out — and loving it. Finally managed to get a hand in, and introduce myself and the guys are genuinely loving what they are doing. They are still processing all of the Kickstarter pledges but it’s all pretty much on track, with the exception of some stuck in customs (mine included) — and yes, I did see all the tweets knocking this particular “investment” (you know who you are!!). What ever you think of this product, or rather, whatever definition you give it, it is a lot of fun, and judging by the ad hoc users, very easy to use. Lovely to catch up with Faberdashery’s Clare Cunningham at the 3Doodler stand too. She reported an excellent day at Selfridges last weekend with the Makies and they were getting plenty of interest here too.

I went to speak with Nick Allen of Create 3D. Another “pulls no punches” kind of guy. I got to see the MONO models they 3D printed up close — all fully finished and painted now. Similarly with Jonathan Rowley and Andrew Dawood of London 3D printing studio Digits2Wigits. Andrew was the driving protagonist behind the 3D printed face of Eric Moger.

Unfortunately, despite numerous walk-bys, I was unable to get to the guys at 3D Hubs, Laser Lines or Concept Laser. I do have photos to prove it though, so, next time?

There were two stand-out projects that I got to see first hand during the show. Both very different but both initiated and fulfilled from a place of passion and determination. Jim Kor and his team are the guys behind the Urbee — it was really satisfying after seeing so many pictures and videos to see this 3D printed electric car up close for the first time. And Jim is quite simply a gentleman. I didn’t get a chance to sit in it, but the journo from Bloomberg did.

And I was thrilled to meet William Hoyle, CEO of TechForTrade. On Thursday William was being inundated by journalists following the launch of a new initiative for the ethical production of 3D printing filament, made from recycled plastic waste. I kind of pushed my way in on one of the interviews, initially just to listen and pick up what I could, but I got an opportunity to introduce myself and boy did we natter. He’s proposed this to some of the big 3D printer vendors, Bre Pettis and Adrian Bowyer included. And as he said, they both agreed that in principle, it was a ‘no brainer.’ But of course there was a disclaimer with that — “so long as it printed well” on the respective machines. William is looking to release HDPE in January, with PET to follow later. Shane is scheduling a more in-depth interview on this, which will follow shortly.

And so I then made my way to the Gallery where all of the 3D printed artwork and sculptures had been curated for this year’s show. And an impressive space it was too. Here’s just some of the amazing 3D printed art that has come into being:

[nggallery id=116]When I finally got to catch up with Kerry Hogarth, the very impressive woman leading the team behind the 3D Printshow, later in the evening at the Global 3D Print Show Awards, she explained to me how it was the designers and the artists that had been a primary driver behind the original conception of the show and giving them a platform. And this year, the inaugural Global 3D Printshow Awards had been conceived to take that a step further and to honour and promote the best in 3D printing. It was a really fun evening, there was the occasional hiccup, as these things never tend to run without a wrinkle or two, but it all added to the charm.

I was lucky enough to be seated on Kerry’s table with her guests who included Jason and Rob. I can’t even begin to explain how much I laughed with them. (I have a couple of pics that will remind me of just how much, but think if I published them, I may just get shot!! Bad joke?? Awww, everyone was doing it!) Anyway, I was really pleased to finally meet Steffi from voxeljet. Steffi and I have corresponded for quite a few years now and it was wonderful to finally put a (beautiful) face to the name. Steffi has been managing the marketing for voxeljet single-handed and a brilliant job she does too, but they definitely need to let her out of the office more! Kevin!!

Lovely to see Lisa and Hannah from Fourth Day who were supporting Team Awesome and Kerry in the run up to the show. And I finally got to meet Josh Harker in person too. Although by then the music was rather loud (a live band, with Kerry’s husband Dave, on bass) albeit very good, but not conducive to any sort of conversation.

And so the awards themselves, which took place at the impressive Honourable Artillery Company venue, and hosted by TV presenter Ashley House. (No? Me neither. But, quick google search, and, apparently, he quit his teaching job after he did ‘Fame Academy’ and then last year he covered the Olympics for Eurosport and has done much work for the BBC too.) He did a good job on the night for the 3D Printshow Awards, was obviously a tad out of his depth on the technology front, but delivered some okay (and some dreadful) jokes including the gun thing and kept things going when the AV couldn’t!

The first award of the evening was for Artist of the Year, which went to Isaie Bloch, who also received a £500 bursary. As did the second winner, Marla Marchant who won Fashion Designer of the Year for her shoes. The Green Award went to the WASP project, while Jake Evill won the Positive Change in the 3D Printing Industry Award for his Cortex Exoskeletal cast. The Inspirational Individual Award went to Andrew Dawood of D2W, and Philip Cotton won in the Educational Excellence category. Rising Star went to Masters and Munn, CJ, in her floor length gown (a few of us went all the way!) definitely delivered the best line of the night in her acceptance speech, when she said if she had thought for a second that they’d win: “I would have ironed my dress!” Brilliant.

The Best Business Newcomer award (the category in which 3DPI was nominated) went to 3Doodler, which, incidentally, Mike had DM’d me earlier in the day to say he had dreamed that that would be the outcome. Spooky! Consumer Product of the Year went to Autodesk 123 Creative, while consumer software went to Anarkik3D. No extra points for guessing who won the Consumer Printer Award. Bre was there and there was no way he was walking away empty handed. This one was always going to belong to Makerbot.

The Best in Show Award, for which there were no nominations ahead of the ceremony, I am delighted to report, went to the man sitting next to me — Jason was genuinely surprised. Nobody else was!

And Brand of the Year Award went to the highly delighted (as in jumping around the room and screaming) Mcor team. Nicely done guys — well deserved.

The awards were 3D printed (of course) by Europac on a Zprinter, and a great job they had done too.

Day two of the show was a slightly slower start for me (although not for Team Awesome or the exhibitors) as Kerry and her girls had deliberately organized for 2500 school kids — of all ages — to attend the show for the morning, ahead of opening up to the public. This was a brave move, on a number of levels, but I think the whole community — even the highly commercial ventures — have bought into the fact that this 3D printing industry of ours is only just germinating and its big future belongs in the hands of the next generation and they need to engage with it as early as possible — whether there is money in it or not. The 3D Printshow should get some major credit for helping to facilitate that in this way. Kudos.

So, to sum up: Lots of new machines at the entry level (it has to slow and consolidate at SOME point soon). Beautiful art & sculpture, with more and more talented designers taking up 3D printing. Oodles of enthusiasm and excitement. A great shot in the arm on the education side. A fantastic celebration of the 3D printing industry. And the promise of more — much more — to come.

Fabulous.

And then I had to take my leave of this wonderful event. Sad but necessary due to mummy duties. Team Awesome though don’t get any sort of downtime. After the London event closed they were all heading to Paris for the next edition of the show in that fair city next weekend, running over two days (15th – 16th November) at the Carrousel Du Louvre. And then in February the 3D Printshow moves stateside for the first time and will be in New York.

While I can’t justify Paris — really hoping to see you in New York! 🙂