Voting shortlists for the 2021 3D Printing Industry Awards are now open. Who do you think should receive top honors this year? Have your say now.

German rapid prototyping firm Cirp GmbH has revealed the 3D printing designs that have made it to the final of the 2021 edition of its annual purmundus challenge.

This year’s contest, which marks the ninth edition of a competition that 3D Printing Industry remains a proud supporter of, will see 35 finalists from 12 countries go head-to-head for the top prize at Formnext in Frankfurt from 16-19 November.

In keeping with the challenge’s focus on ‘Innovation in Progress,’ each shortlisted entry showcases how innovation is becoming a systematic art, that enables a fluid transition from prototyping to the series production of 3D printed products.

Oven-ready innovation

This year’s participants have taken the brief of proving 3D printing’s potential as a ‘mass-customisation enabler’ to heart, developing unique products with applications in medicine, biotechnology, 4D printing, virtual reality (VR), robotics, e-mobility and powertrain technology, as well as mechanical and plant engineering.

Altair Engineering’s ‘BushBot-Chair’ is a prime example of this, as its NASA Bush Robot-inspired design is purpose-built to ‘grasp’ bodies of any geometry, much like a hypothetical ‘fractally branching grasping machine.’ The furniture itself features 24 ‘contact stars,’ built on four articulated branching-systems, that rest upon three further sub-branch supports.

SLS 3D printed from PA12, the chair’s sitting surface also includes nine pivot points that allow it to adjust smoothly to the human body, while its shape is structurally-optimized to minimize material usage and control the kinematics of its ‘trees.’

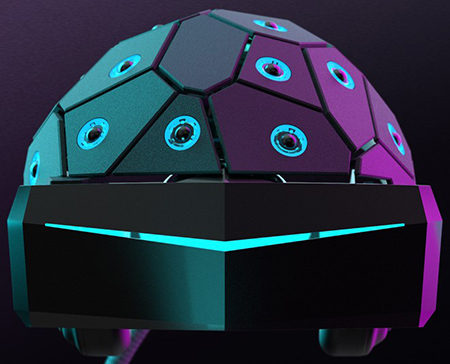

Design firm Tom Ayton’s ‘Yullbe’ entry is similarly visually-impressive, but fulfills an entirely different purpose in that it creates VR experiences. Once connected to a backpack and foot trackers, the helmet can liaise wirelessly with eight others, enabling wearers to adventure together in a virtual world. Using EOS 3D printing, the company found it possible to make the Yullbe light, breathable and cost-effective.

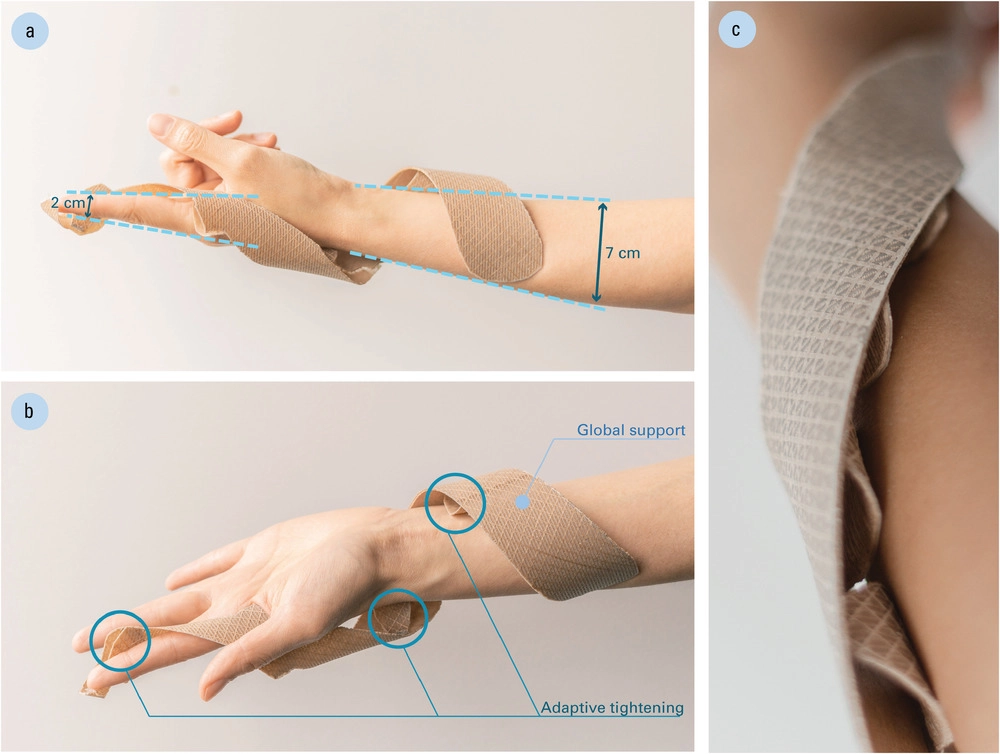

The University of Stuttgart will also be among the finalists thanks to its 4DmultiMATS’ 4D printed wrist splint. Previously covered by 3D Printing Industry, the vine-inspired support is capable of self-adjusting to the anatomy of individual patients, while bringing medical design ‘one step closer to nature.’ Leveraging a desktop 3D printer and wood-polymer composite, the team has already created a working prototype.

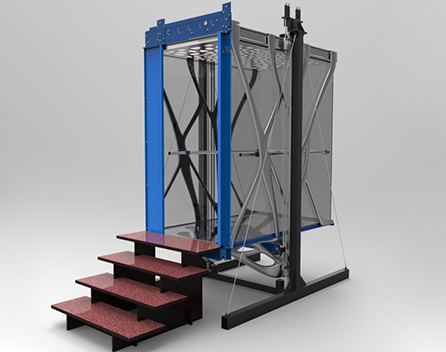

Having made it to last year’s final, Metal 3D printing firm MX3D is back for the 2021 contest, with a new initiative that’s seen it redesign the elevator cart. Built using its proprietary WAAM process alongside elevator firm Schindler, the unique lift is topologically-optimized for reduced weight. Adopting MX3D’s technology has also allowed Schindler to rapidly iterate its product design and in-source related parts.

Among the other finalists, Belgian student Bram Peirs’ ‘From Waste to Wind’ project’ is also a stand-out entry in this year’s contest. Fully-3D printed from PLA, the engineer’s ‘Propel-E 450’ wind turbine is said to be capable of generating sufficient electricity to meet the needs of any small household. What’s more, the device’s design has been made available online, with parts costing just €300 to build.

Winners of the 2020 purmundus challenge

Last year’s contest saw another 35 finalists compete for purmundus challenge glory at the virtual Formnext Connect. Huhn Cycles’ ultra-lightweight titanium Moorhuhn Bike won first place, with HKK Bionics’ ‘bionic glove’ Exomotion Hand One orthosis coming second. Third place was awarded to the Sneaker Zero, a customizable, fully-recyclable sneaker, which was designed by the Zellerfeld Shoe Company.

Elsewhere, 3D printing software provider Taktilesdesign’s Tactile Color Compass gained a special mention from the judges. Developed in collaboration with Stratasys and Roland UV Printing, the device demonstrated the ability to guide visually-impaired users through landscapes, pictures and everyday objects by relating tactile surfaces to colors.

Anatomical model provider ANAMOS was also awarded the Innovation Prize for its realistic 3D printed human heart model, while the competition’s Simulation Driven Design award went to Inspire AG, ETH Zurich, and Gressel for their automated gripping technology. Finally, Victoria University of Wellington pupil Yejun Fu gained the Newcomer award for her investigation into bio-based 4D printing materials.

Judging criteria and prizes

As well as being judged against this year’s theme, entries will be scored using nine criteria: design, degree of innovation, relation to announcement, appropriateness of design for 3D or 4D printing, potential in comparison to conventional production, economic potential, societal potential, relevance and user experience.

Each design is set to be assessed by an international jury of professionals, including representatives from Volkswagen AG, Loughborough University, Beijing University of Technology, Deakin University, hyperTunnel and more. In particular, the panel has said that this year, they’re evaluating the product benefits of entries in terms of use, economy and aesthetics, as well as the design itself and the innovation.

Overall, some €30,000 worth of prizes will be awarded to finalists, with the winner receiving €3,000, runner-up securing €2,000, and third place gaining €1,000, and all three being gifted access to the Altair Inspire Studio software. The usual Special Mention, Simulation-Driven Design, Innovation Prize and Public Choice awards also return alongside the Newcomer Prize, which debuted during the 2020 challenge.

Winners will be announced via an in-person award ceremony, as Formnext returns to its traditional physical format this year, on 18th November 2021. For those that can’t make it to Frankfurt, the contest’s conclusion is set to be broadcast live from the show, ahead of which, more details about its 35 finalists can be found here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Tom Ayton’s ‘Yullbe’ 3D printed VR headset. Image via purmundus challenge.