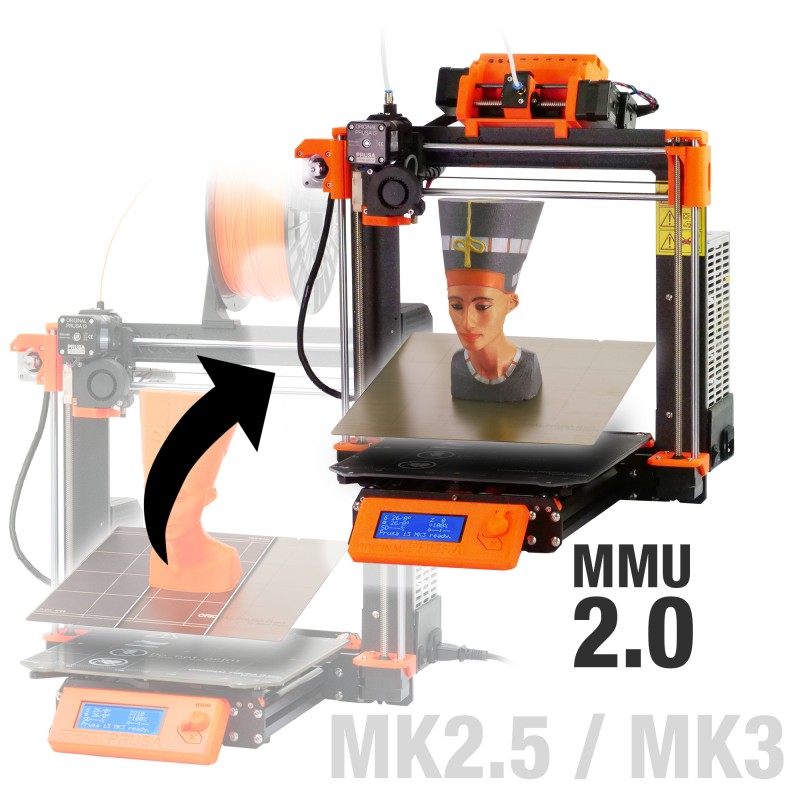

Prusa Research, an award-winning manufacturer of open-source 3D printers, has released an upgrade which enables its i3 MK3 Prusa to print using 5 different materials. A new firmware for the Original Prusa i3 MK3 and MK 2.5 has also been released.

The Multi Material Upgrade 2.0 (MMU2) is available to pre-order at Prusa’s e-shop for $299 (tax excluded).

The founder and CEO of the company, Josef Průša, wrote on the company’s blog, “What we have here is a one-of-a-kind multi-material printing addon that is fully integrated with the printer, so everything is perfectly synchronized and the whole thing works seamlessly as a single unit. It’s just like printing on the standard MK3. Plus, our MMU 2.0 is the only device that supports up to 5 materials loaded at the same time.”

3D printing with 5 filaments

The Multi Material Upgrade 2.0 makes significant hardware changes to the first generation MMU tool. Průša says, “we wanted a simpler, more efficient design.”

In the upgrade, the number of extruder motors is cut to 1 from 4. The MMU2 upgrade enables the user to print with 5 different types of filaments and uses direct drive feed instead of a Bowden drive used in MMU1. Průša explains that the Bowden drive was causing “issues with flexible filaments, proper retractions, and other things.”

A motorized selector head is equipped with a built-in blade which cuts off the filament if it is stuck during unloading. This upgrade makes the printer less prone to jamming and more adaptable with regards to accepting different quality filament.

Operational features are also included in the tool. Control buttons are added on top of the MMU2 body for moving the selector head and loading and unloading filaments. These buttons can also be used to “calibrate the length of the PTFE tube.”

Prusa’s firmware upgrade

Prusa’s new firmware 3.4.0 for Original Prusa i3 MK3 and MK2.5 has improved the 3D printers’ filament flow capabilities. Original Prusa i3 MK3 printers are equipped with filament sensor, which keeps track of the loaded filament. This filament sensor can notify the user of stuck and runout filament. Průša explains, “the part of the software responsible for analyzing the filament flow has been completely rewritten to improve the precision and reliability of the sensor […] it means that the sensor can recognize filament runout with greater accuracy and the number of false detections drops significantly.”

Most widely used 3D printer

In 2016, the Prusa i3 was the most widely used 3D printer in the world. One reason for its popularity is its open-source hardware which allows rapid improvements to the printers hardware and printing capabilities.

In the past, Josef Průša has also spoken to 3D Printing Industry about his support and commitment to the open-source hardware.

For more news related to 3D printing and open-source, subscribe to our 3D printing newsletter, or join us on Facebook and Twitter.

If you are looking for a new career, visit 3D Printing Jobs.

Featured image show the Original Prusa i3 MK3 Multi Material Upgrade. Image via Prusa3d