Biotechnology specialist Pixelbio has developed a novel 3D printed molecular biochip with the potential to ramp-up the pace of clinical genetic testing.

Utilizing a Formlabs 3D printer and Black Resin, Pixelbio has been able to create new ‘HuluFISH’ sensing devices, capable of using multi-colored probes to detect several different gene codes simultaneously. In doing so, the firm has managed to reduce its costs and lead times while producing a flexible clinical tool that could now help accelerate cancer diagnoses as well as the R&D of other drugs and vaccines.

“Thanks to the Form 3’s high precision and print speed, we are able to use it to print tubes smaller than 1 mm into a tiny space,” said Sheng Liu, Development Director at Pixelbio. “We also found that once the design was right, we could produce the part we needed quickly and on a large scale, which would have been very expensive per unit and not necessarily suitable for our needs [with prior technologies].”

Harnessing the potential of ‘FISH’

First introduced in the 1960s, in situ hybridization has become a common method of identifying the location of specific nucleic acids, DNA and RNA, within tissues, cells and chromosomes. In general, the technique involves the use of chemical or radioactive probes, often to detect cancer cells in cytologic specimens, and it effectively enables clinicians to achieve early disease prognosis and treatment.

Building on this approach, such scientists are now increasingly turning to Fluorescence in situ hybridization or ‘FISH’ techniques, through which they attach colored markers to certain genes to lend them greater microscope visibility, but even though the method enables single molecular detection, it remains limited to identifying one gene at a time.

To get around this, Pixelbio has developed ‘HuluFISH,’ a flexible 3D printed biochip that allows clinicians to track a larger number of genes concurrently. Marketed as the ‘first individualizable multiplex smFISH solution,’ the firm effectively offers to produce the chips as a service, which allows clients to rapidly order from a selection of marked genes and receive the corresponding molecular devices for testing.

Advanced DNA-detecting biochips

Using current biochips with 0.8-1.2 mm channels, it’s possible to assess samples by identifying genes with a laser, but such devices often need to be adjusted depending on the makeup of the liquids being tested. What’s more, given that probes come in many shapes and sizes, the specifications of biochips are always changing, necessitating a prototyping process that can take months to get right.

By contrast, since adopting Formlabs’ technology, Pixelbio has been able to create the HuluFISH in-house, reducing its related production costs and lead times. Thanks to its inherent low-opacity, the Black Resin has also proven ideal for chip manufacturing, and the firm is now using the material to expedite the R&D of its next generation of products.

Elsewhere in its lab, Pixelbio has also deployed its Form 3 along with Formlabs’ Clear Resin to produce precision-fit closures that protect the liquid inlets of its chips, and moving forwards, it now intends to continue 3D printing the HuluFISH at its Hamburg factory, while developing unique microarray chips at its R&D complex in Heidelberg.

In terms of the HuluFISH’s future potential, the flexibility of its in-built probes could make it ideal for identifying different strains of COVID-19, analyzing their progression and advancing the development of enhanced vaccines. With this in mind, Pixelbio is participating in the NIH’s Rapid Acceleration of Diagnostics (RADxSM) initiative, through which it aims to develop improved COVID-testing technologies.

“[HuluFISH] will make the diagnosis of tumors or diseases easy and precise, and will change the way we diagnose and treat diseases in the long run,” concluded Liu. “We are confident that our probe can accelerate the development of drugs and vaccines by enabling the detection of SARS-CoV-2 and its receptor ACE2 mRNA at the single-cell molecule level.”

3D printing in COVID-19 testing

Since the pandemic’s global outbreak last year, COVID-19 testing has come on leaps and bounds, but this hasn’t stopped scientists experimenting with new ways of optimizing the process. At Wageningen University, researchers have developed coffee capsule-based 3D printed COVID-19 home test kits that can be produced for less than 20p each.

Likewise, a team at Carnegie Mellon University (CMU) 3D printed a rapid COVID-19 sensor in September 2020 that’s capable of detecting antibodies in around 10 seconds. Made with Optomec’s patented Aerosol Jet Printing (AJP) technology, the device is specifically designed for reuse, allowing it to be deployed multiple times and speed up the testing process.

Elsewhere, scientists at the Weizmann Institute of Science have 3D printed an ‘electronic nose’ accessory that enables it to ‘sniff-out’ COVID-19 within infected individuals. Using the additive manufactured sampling valve, the team has been able to safely train an ‘eNose’ to identify signs of the disease at a testing center in their native Israel.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

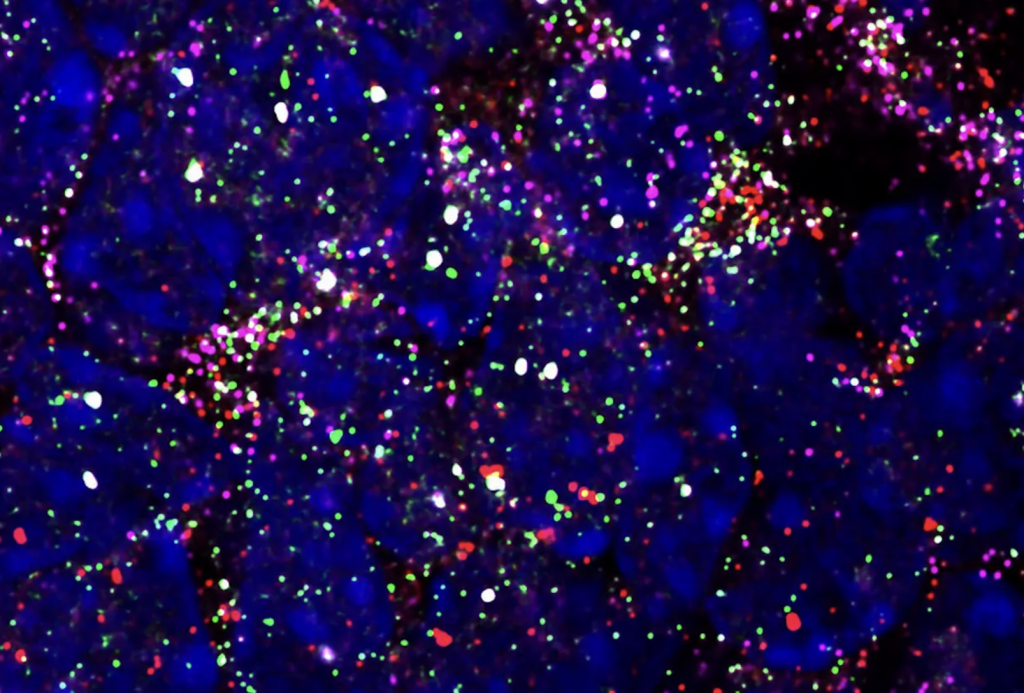

Featured image shows color-labelled molecules identified using Pixelbio’s 3D printed chip. Image via Formlabs.