3D printer manufacturer 3D Systems has announced a co-development agreement with CollPlant, a regenerative medicine firm, to develop 3D bioprinted soft tissue structures for breast reconstruction treatments.

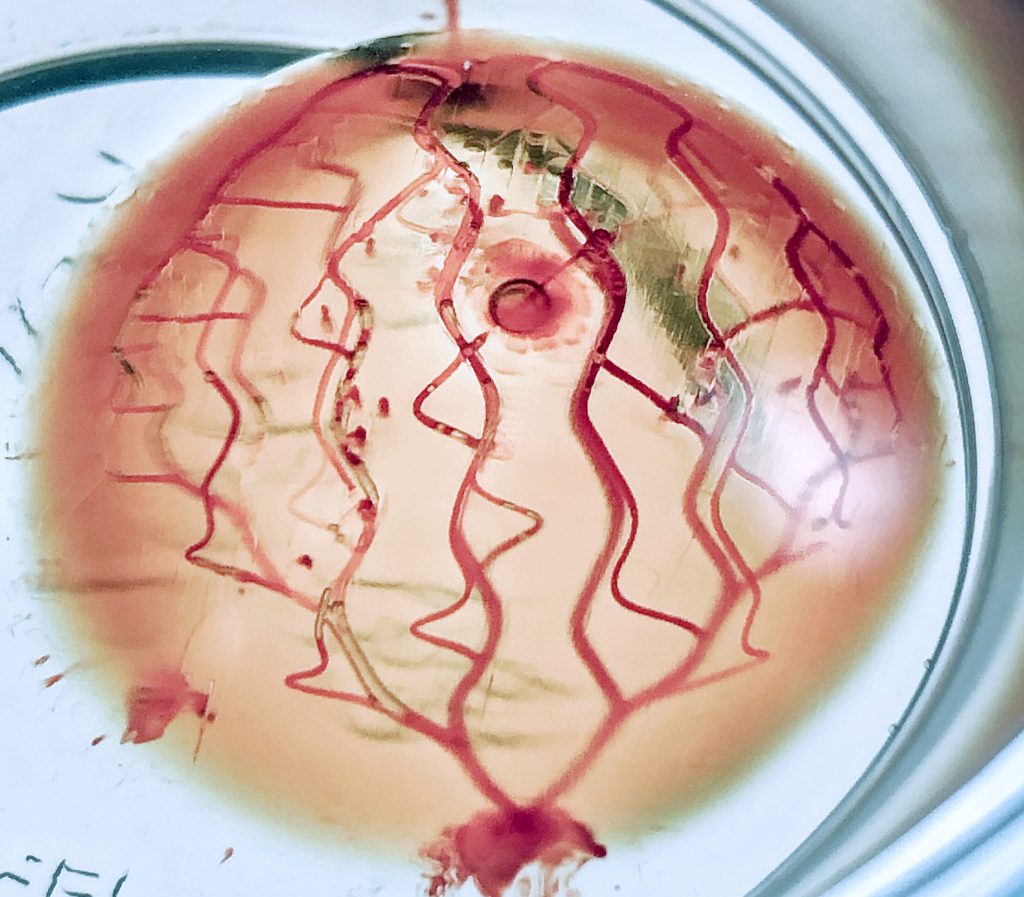

Implemented in conjunction with a breast implant, the soft tissue structures will be used to provide support for the lower breast and expand the implant pocket, increasing the overall coverage of the implant. Leveraging their joint expertise in 3D bioprinting, the companies will personalize these structures to better match the anatomies of their patients. The ultimate aim is to improve the success rates of breast reconstruction surgeries for cancer survivors.

The news comes after 3D Systems announced intentions to increase its investment in 3D bioprinting and regenerative medicine back in January.

Dr. Jeffrey Graves, President and CEO of 3D Systems, states, “Through this project we’re embarking on with CollPlant, we’re exploring a novel application that could offer a new reconstruction treatment for breast cancer survivors. It’s inspiring to be involved in a project that has the potential to have such a positive impact on the human condition.”

The issue of breast cancer

The World Health Organization states that 2.3 million women worldwide were diagnosed with breast cancer last year. It is the world’s most prevalent cancer in women with almost 700,000 deaths every year.

The vast majority of those diagnosed with the condition require either partial or full removal of breast tissue. With modern day treatments, however, survival rates are greater than 90%, meaning more and more women are seeking improved breast reconstruction treatments.

Most of these breast reconstruction surgeries employ soft tissue matrices from either human cadavers or animals, but these sources are in short supply and there is too much variability for treatments to be considered reliable. By using foreign mammalian tissues, there is also the risk of evoking an immune response, which can slow down the healing process.

Yehiel Tal, CEO of CollPlant, adds, “We’ve joined forces with 3D Systems to offer a regenerative soft tissue matrix that may significantly increase the addressable market for soft tissue reinforcement in breast implant procedures. A regenerative solution can increase safety, eliminate product variability, and enhance results by promoting new tissue growth.”

The co-development agreement

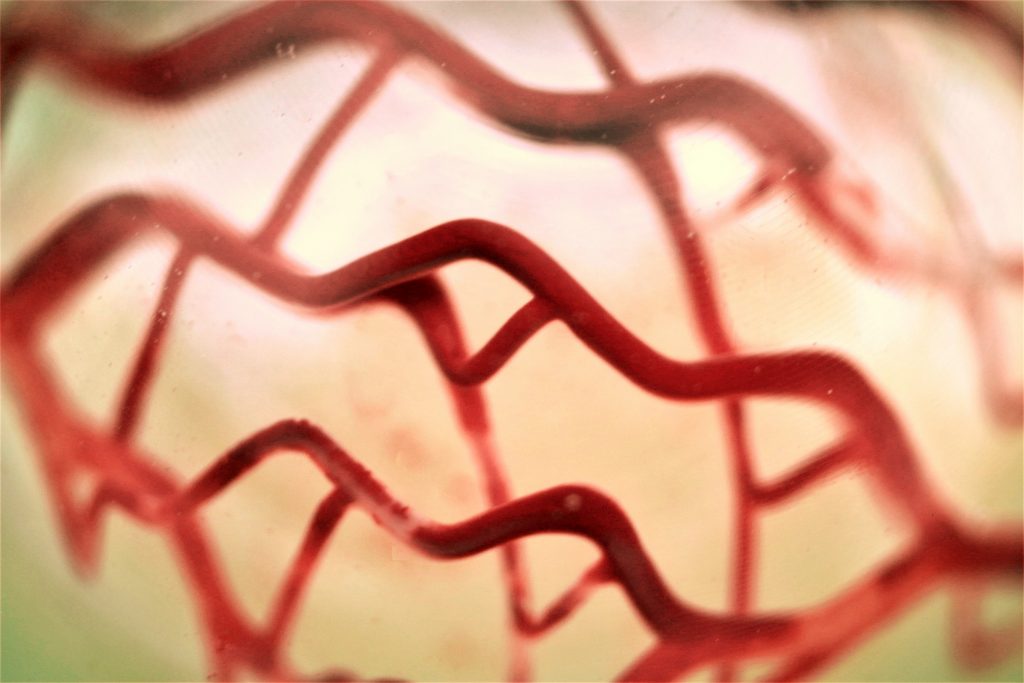

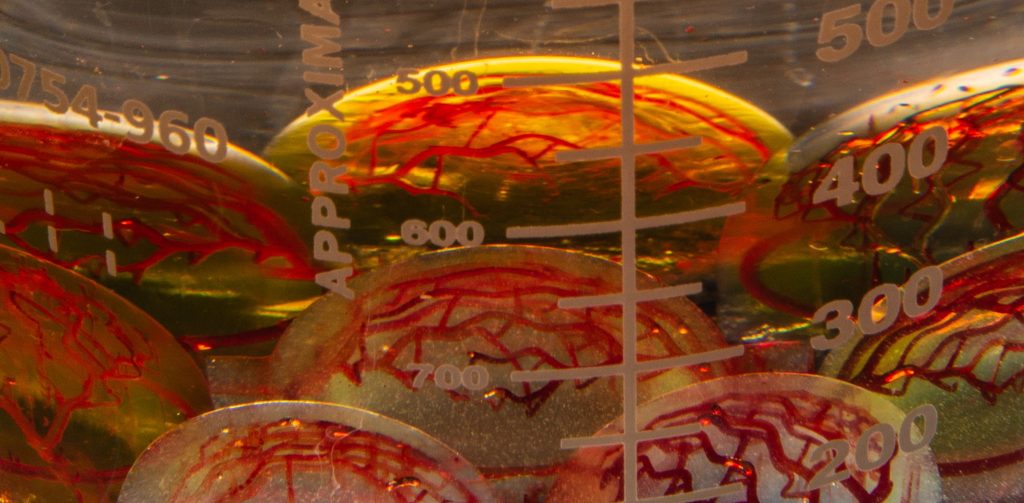

As per the co-development agreement, the firms will 3D bioprint patient-specific soft tissue matrices using bioinks based on recombinant human collagen (rhCollagen) – an area in which CollPlant is an expert. The company uses a proprietary plant-based technology to enable the production of 3D printable rhCollagen bioink, which is reportedly identical to the natural collagen we produce on a daily basis.

The matrices will combine mechanical performance with properties that promote cell infiltration and proliferation, further encouraging tissue regeneration at the implant site. 3D Systems and CollPlant both believe the project will yield tissue matrices that perform far better than what is currently possible, as well as being consistent and safe. Since the treatments will be based on a plant origin, there’s also no risk of an immune response and no supply shortages.

Tal concludes, “We are pleased to deepen our collaboration with 3D Systems as part of CollPlant’s strategy as a leader in regenerative medicine.”

The CollPlant co-development agreement is the latest in a line of 3D Systems partnerships and acquisitions, all of which are part of the regenerative medicine roadmap. Just last month, the company announced the acquisition of Allevi, a Pennsylvania-based 3D bioprinter developer. Founded in 2014, Allevi’s 3D bioprinting technology and bioinks are found in over 380 medical and pharmaceutical laboratories across the world.

Elsewhere, 3D Systems has also previously partnered with Antleron, a Belgium-based biotechnology company, to develop regenerative products for personalized patient care. Through the partnership, the firms worked to transition from static 2D cell cultures into usable, bioreactor-based 3D cell cultures, enabling new methods of producing medical implants, vaccines, cell therapies and more.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D bioprinted soft tissue scaffolds. Photo via 3D Systems.