Philadelphia-headquartered Allevi has launched a new 3D bioprinter – the Allevi 3. Complete with three extruders, the new system allows users to combine multiple biomaterials to build the foundations of complex tissues and devices.

Allevi powered medical research

Allevi, previously known as BioBots, was founded in 2014 with a mission to “make it easy to design and engineer 3D tissues.” As such, the company works on all parts of the “3D printing trifecta,” developing software, materials and hardware suited to the production of biological matter.

With the release of the Allevi 3, the company now has four 3D bioprinters in its portfolio, each numbered according to its extruder count: the Allevi 6, the Allevi 2 and the Allevi 1, which was released in February 2018.

Working closely with its customers, Allevi 3D bioprinters have been cited in numerous studies, including lab-on-a-chip activity at the Massachusetts Institute of Technology (MIT), and bioink bench marking at Stanford University.

Most recently, the company announced a partnership with Made In Space that aims to develop a 3D bioprinter that can work in low-gravity conditions.

Highlights of the Allevi 3

Each of Allevi’s 3D bioprinters are designed for ease-of-use with pre-made protocols for all bioinks offered by the company. Importantly, the Allevi 3 also comes with auto calibration, and both the extruders and print bed can be switched out in lieu of future updates.

With a consideration for the experimental aspect of 3D bioprinting, the Allevi 3 is an open system giving the user complete control over every parameter, optional use of a self-made bioink, and the ability to operate from either PC and MAC OS.

The 3D bioprinter has a build volume of 90 x 130 x 60 mm (W x L x H), and occupies a footprint of 406.4 x 355.6 x 355.6 mm. Across all axis, the Allevi 3 is capable of a single micron precision.

Quotes for the Allevi 3 are available on request from the company, and subject to optional material packages such as the Starter Bioink Kit or Organ-on-a-chip Kit.

Allevi 3 full technical specifications

Dimensions: 406.4 x 355.6 x 355.6 mm

Weight: 22 lb (9.9 kg)

Power requirement: 110V – 240V

Connectivity: USB

Operating Systems: PC and Mac OS

Construction: Aluminum frame

Stepper motors: 0.9 degrees step angle

X,Y Precision: 1 μm

Z Precision: 1 μm

Extruder: Three, heating and cooling

Max temp – low: 4°C

Max temp – high: 160°C

Photocuring: 365 nm or 405 nm

Accepted print files: .stl, GCode

Printing technology: FDM/FFF

Build volume: 90 x 130 x 60 mm (W x L x H)

Print resolution: 150 μm

Build structure: Petri dish, tissue culture plate, glass slide

For more of the latest 3D printing hardware, software and materials releases subscribe to the most widely read newsletter in the industry, follow us on Twitter, and like us on Facebook.

Search and post 3D Printing Jobs for new opportunities in academia and industry.

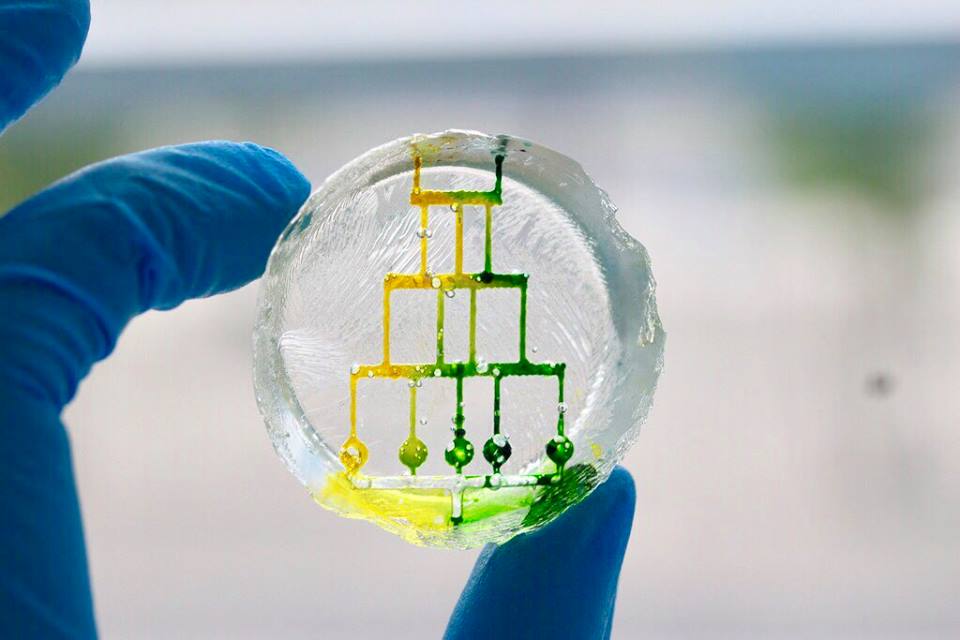

Featured image shows the Allevi 3 bioprinter. Photo via Allevi