Industrial 3D laser scanning company Perceptron, headquartered in Plymouth, Michigan, has added a new product to its V systems series.

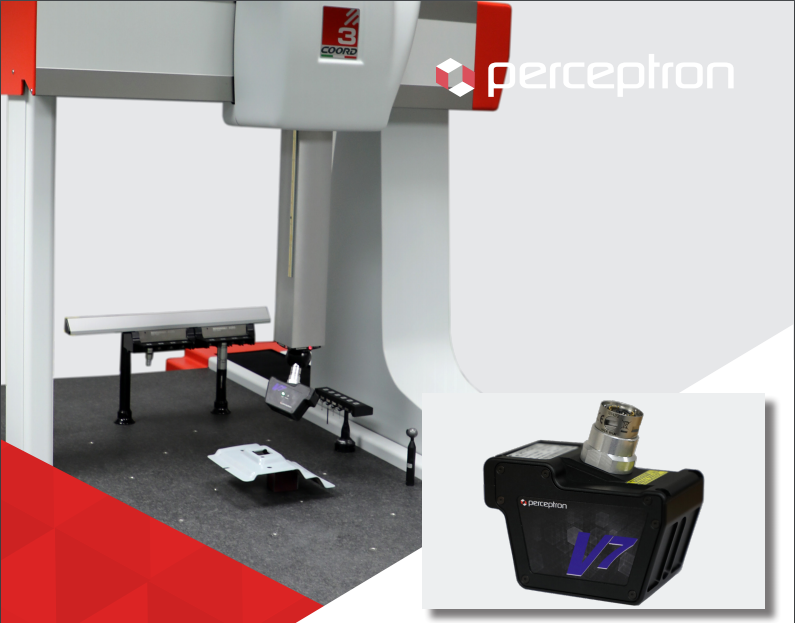

Named the V7, this 3D scanning module is made for use inside coordinate measuring machines (CMMs), facilitating automated non-destructive testing (NDT) and file capture.

Rick Van Valkenburg, Vice President Global Sales and Marketing for Perceptron, comments:

“The V7 scanner is a versatile tool for CMM users to quickly scan features and freeform surfaces,”

“…Perceptron’s three decades of experience with measurement algorithms enables us to generate pristine point clouds for reverse engineering and provide rapid feature measurement directly in TouchDMIS [software] with the V7 sensor.”

Founded on automotive expertise

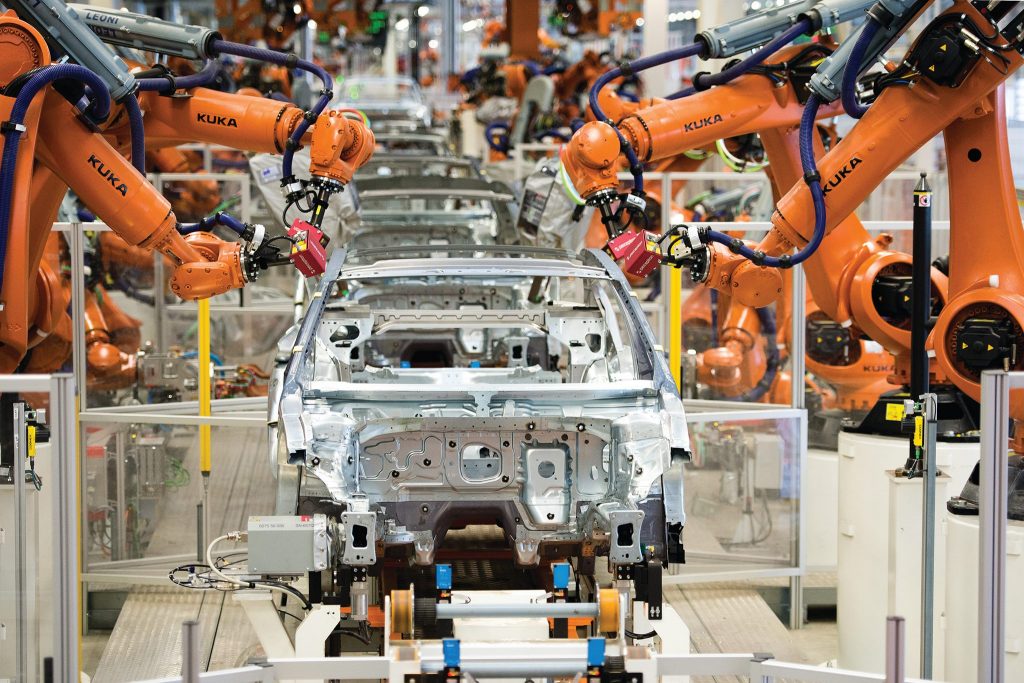

Perceptron was founded in 1981 by graduates of The General Motors Institute (now Kettering University) in Flint, Michigan. As such, the company has always worked closely with the automotive industry.

After over 30 years in the industry, the company’s product portfolio now stretches across nine lines: from robot guidance and CMMs, to sensor technology and software.

This offering includes the TouchDMIS platform, designed to help simplify CMM file processing.

Inside the Perceptron V7 3D laser scanner

The Perceptron V7 is a blue laser system, meaning it can easily capture data from surfaces otherwise challenging to typical red lasers. Dark, reflective and geometrically complex objects can be scanned with this module without the use of reference stickers, or dulling spray.

It is designed to be used inside a Coord3 CMM, offered as bridge, large gantry and horizontal arm systems dependent on application. For example, the horizontal arm CMMs offered by Perceptron are made for inspecting car bodies.

With a large field of view (88mm W and 100mm D) the V7 is adept at capturing large, geometrically complex areas. In terms of speed, the scanner works at a rate of 1280 points per line, creating up to 64,000 points p/s.

A valuable tool for reverse engineering, the V7 is also capable of point cloud to CAD comparison when measuring tolerance.

In terms of pricing, the company promises the V7 provides “high quality scanning at an affordable price to maximize the use of your Coord3 coordinate measuring machine.” Further costing information is available directly from Perceptron on request.

Perceptron V7 technical specifications

Length: 114.26mm

Height: 112.65mm

Width: 65mm

Weight: 456g

Operating Temperature: 10°C to 40°C

Communications: GiGE Ethernet

Laser Class: 2M

Laser Wavelength: 450nm (Blue)

Certification: UL, CSA, CE

Safety: IEC 60825-1:2007

Protection: IP54

Standoff: 67mm (+/- 2mm)

Depth of Field: 100mm (+/- 2mm)

Near Field Width: 48mm (+/- 2mm)

Far Field Width: 88mm (+/- 4mm)

Mean Point Resolution: ≤40µm at mid field

Points per Line: 1280

Scan Rate: Up to 64,000 points per second

Update Frequency: Up to 50Hz

For more of the latest 3D scanning hardware news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Join 3D Printing Jobs to find your next opportunity.

Featured image shows TouchDMIS CMM interface. Image via Perceptron