A student from the University of Pennsylvania has developed a new UAV configuration that has the full range of motion of more complex drones, but only requires two motors to fly. The drone can be made with several 3D printable parts and components that can easily be purchased off the shelf.

Working from the Modlab – or The Modular Robotics Laboratory – at UPenn, student engineer James Paulos has essentially simplified the design of a standard UAV without reducing functionality. Typically highly maneuverable drones require four or more motors, plus countless servos, linkages, and ball joints to move. Paulos explains his detailed research paper:

“Conventional UAV formats applied to smaller and smaller micro air vehicles lead to significant design challenges. A swashplate-controlled coaxial helicopter must find room in its mass, size, and cost budget for four actuators (two big rotor motors, two swashplate servo motors) and a complex linkage assembly. A quadrotor must similarly support four motors and face the practical problems of rapidly shrinking rotors. Our new rotor system provides significant system simplifications while retaining all the advantages of cyclic control.”

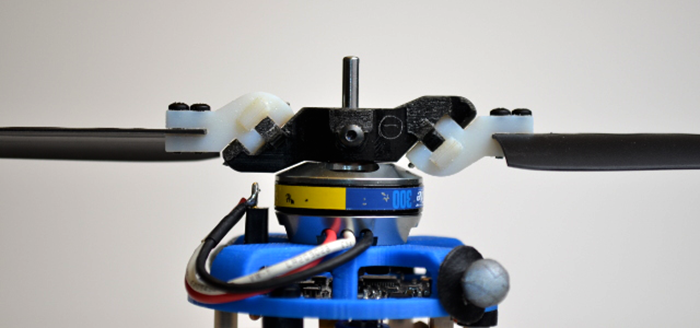

Paulos’ design eliminates most of those parts and replaces them with a simple inclined hinge that connects the propellers to the propeller hub. The UAV’s thrust, roll, and pitch are all controlled with simple adjustments to the rotor angle, causing the drone to effortlessly alter course, speed, altitude, and even orientation. This incredibly simple redesign will allow an entire new class of drones to be created using inexpensive and easy to acquire parts and supplies. Here is a video of Paulos’ drone in action:

The drone works amazingly well, however the hinges, while simplifying the mechanics and hardware, will require more complex software and control modifications in order to be easy to operate. However, Paulos’ UAV motor and drive system is an ongoing research project that he will be continuing to develop alongside his Penn instructor, Professor Mark Yim. You can find out more about the design and how it works by reading the entire research paper here.