Researchers from Connecticut-based Oxford Performance Materials (OPM), and McGill University, Canada, have demonstrated the capabilities of accelerated bone regeneration using 3D printed PEKK implants.

According to a study published in Nature, OPM’s additively manufactured OsteoFab implants seeded with human synovial fluid mesenchymal stem cells (hSF-MSCs), that enable cartilage repair, show strong evidence of new bone formation. This could aid in treatments for critical-sized bone defects, reducing the need for invasive procedures such as bone grafting.

Close to the bone

As stated by the study, approximately 2.2 million bone grafting procedures are performed annually worldwide in medical disciplines including orthopedics and dentistry. This surgical procedure replaces missing bone to repair life-altering fractures in the human body.

Although common, bone grafting can have negative effects such as prolonged recovery time in patients, and donor site morbidity, i.e., complications due to harvesting flap/graft from a patient. “Stem cell-based therapy for bone regeneration has been considered as the most promising approach to overcome the limitations of bone grafting,” the researchers explained.

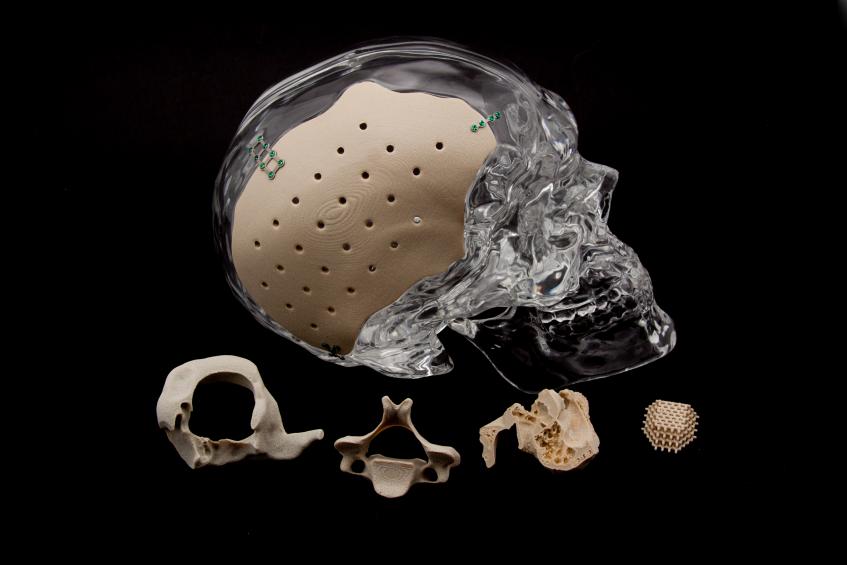

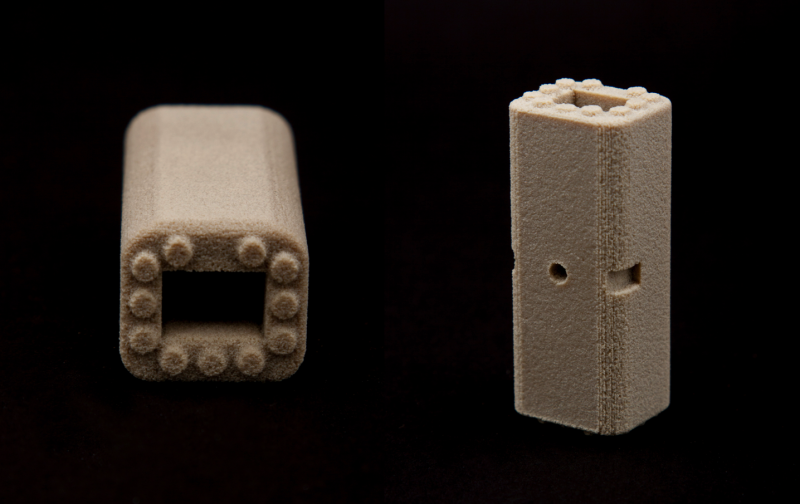

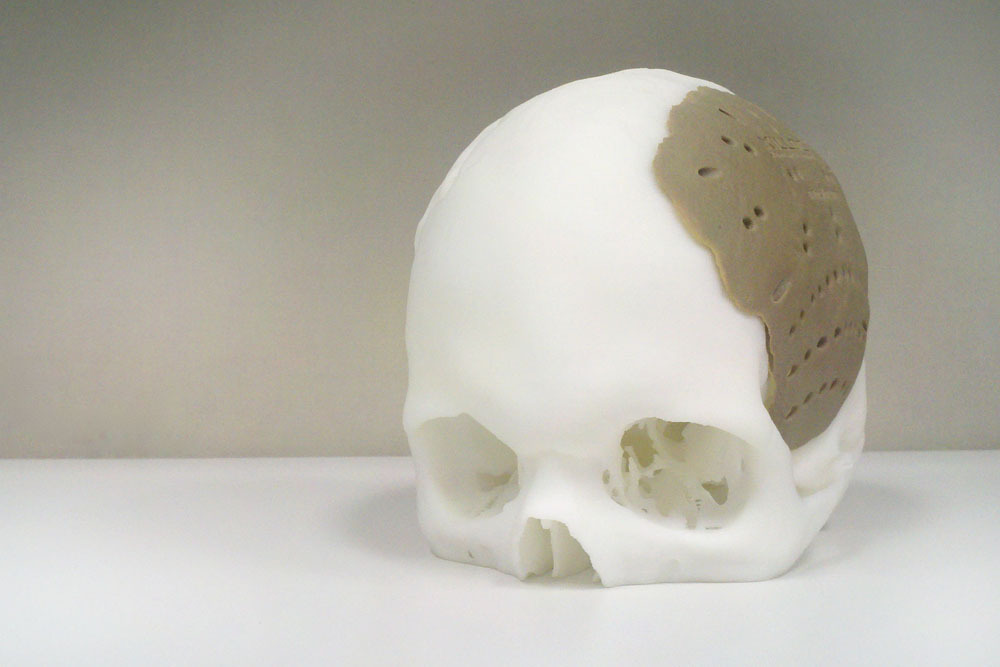

The OPM and McGill team sought to explore cell types and biomimetic scaffolds for bone regeneration. Thus, OsteoFab technology was used to create scaffolds for critical-sized bone defects in a rabbit calvarial (skullcap). This is done using SLS technology on an EOSINT P800 3D printer. The study adds:

“Unlike commonly used PEEK material, OsteoFab 3D printed PEKK showed no observable immunological rejection and no increase in inflammatory response cells.”

PEKK scaffolds for bone regeneration

The biocompatibility of PEKK scaffolds with hSF-MSCs was evaluated after seven days. It was found that cell attachment and cell growth assays were evident as a result of a rough surface with open micropores. The researchers add:

“Our in vivo results supported the use of PEKK as a scaffold for hSF-MSCs. Our micro-CT and histological results revealed a distinct increase in bone regeneration when either hSF-MSCs (PEKK + SF) or osteogenically-induced hSF-MSCs (PEKK + OS) were seeded on PEKK scaffolds. [Furthermore], in vitro results showed that hSF-MSCs attached, proliferated, and were osteogenic on PEKK.”

It was concluded that the combined implantation of PEKK and hSF-MSCs is a promising therapy to regenerate large bone defects.

“Combination of polyetherketoneketone scaffold and human mesenchymal stem cells from temporomandibular joint synovial fluid enhances bone regeneration” is co-authored by Mayumi Umebayashi, Mohamed-Nur Abdallah, Guoying Dong, Michael G. Roskies, Yaoyao Fiona Zhao, Monzur Murshed, Zhiguang Zhang, and Simon D. Tran.

For the latest additive manufacturing research, subscribe to the3D Printing Industry newsletter and follow us onTwitter and Facebook.

Searching for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows OsteoFab 3D printed PEKK implants. Photo via Oxford Performance Materials.