In the future, researchers hope to be able to produce 3D printers that can actively contribute to a patient’s healing process. Though relatively conceptual at this stage, in-situ 3D printing directly at the point of an injury is currently undergoing research for its ability to rejuvenate the skin.

The next level in this concept, in-situ 3D printing for bone regrowth, has been presented in an International & American Associations for Dental Research session by Dr. Venu G. Varanasi, Assistant Professor of Biomedical Sciences at Texas A&M University (TAMU).

“Our goal,” explains Dr. Varansi, “is to heal the defect or fracture site rapidly, as if nothing ever happened,”

“We want to develop these methods and materials so that someday we can treat certain types of bone defects like they are dental fillings.”

Putting in-situ 3D printing to the test

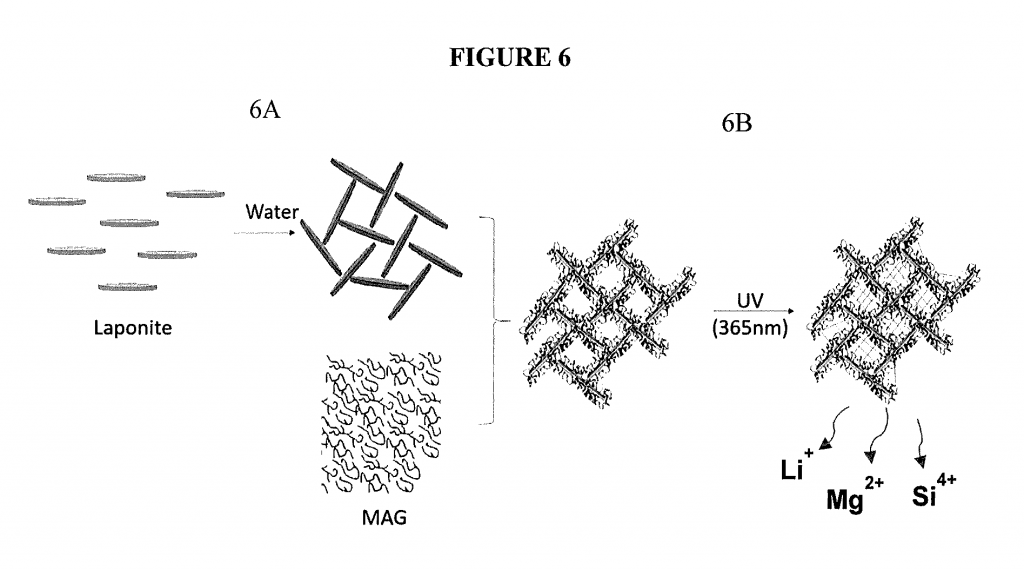

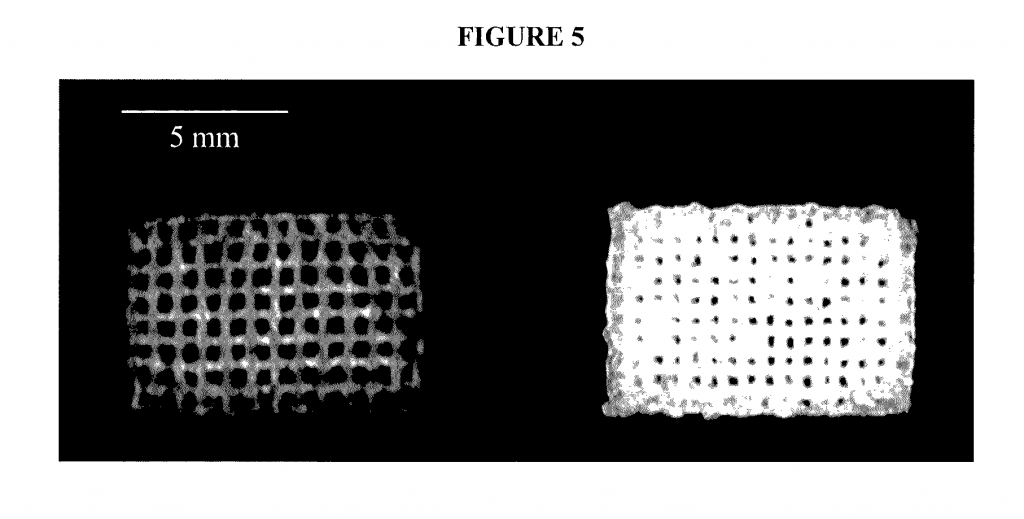

Dr. Varansi’s in-situ 3D printing has been tested on a cranial defect in lab rats. The 3D scaffolds, made of nanobiosilica (a biocompatible form of silica) were 3D printed and simultaneously cured under UV light in the upper part of the animal’s skull.

“In our laboratory we tested several nanobiosilica-based 3D scaffolds with adequate 3D printing properties to potentially improve implantability and rapid bone healing capability,” explains Dr. Varansi. “We hypothesized that these scaffolds formed the intended porosity and chemistry for bone and vascular healing.”

The hope is that these scaffolds can heal large cavities in bone much faster than its traditionally manufactured, and often metal, counterparts.

From in-patient to out-patient recovery

Pores in the direct 3D printed scaffolds allow for the absorption of blood and essential growth factors, making the implant much more symbiotic with the body’s natural healing process.

4 weeks after operating, Dr. Varansi’s study found that 55% of the bone defect had healed, compared to just 11% of the empty control model. The results are a promising foundation for the development of in-situ 3D printing of bone scaffolds for rapid treatment of defects.

By investigating other suitable types of bone, and conducting extensive studies on the implants, Dr. Varansi hopes to be able to turn the treatment of bone defects into, “out-patient procedures where the patient goes home to heal with the support of their loved ones and with reduced medical expenses owed to extended hospital stays.”

Dr. Varansi’s ongoing research will be undertaken in the Bone-Muscle Group of the University of Texas at Arlington in collaboration with TAMU.

A patent for “In vivo live 3d printing of regenerative bone healing scaffolds for rapid fracture healing” has been assigned to TAMU crediting Venu G. Varanasi, Azhar Ilyas, Philip Roger Kramer, Taha Azimaie as the inventors.

For more research and medical news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking to get involved in a new additive manufacturing project? Join 3D printing jobs for the latest vacancies in software, hardware and materials.

Vote now in the 2018 3D Printing Industry Awards for research/academic of the year and more. Want to design the trophy? Enter the 2018 3D Printing Industry Awards design competition. sponsored by Protolabs now.

Featured image shows the process of 3D fabricating scaffolds used in Dr. Varansi’s research. Image via US20170143831A1 patent application