The National Research Council of Canada (NRC) has launched a new initiative focusing on the research, development and adoption of cold spray additive manufacturing (CSAM). In partnership with Quebec-based surface engineering company Polycontrols, the NRC plans to open a specialized CSAM facility in February 2020. Based at the NRC in Boucherville, Quebec, the Poly/CSAM center will work to scale the CSAM process for mass production.

Polycontrols has proven expertise in cold spray implementation for aerospace and transport industries. Through this project, according to VP Operations Luc Pouliot, the company is hoping “to showcase its capabilities as a large-scale manufacturing integrator.”

The first phase of the project will be conducted by Polycontrols over the next six years with a $4 million CAD (approximately $3 million USD) initial investment from Investissement Québec, the Business Development Bank of Canada, and Bank of Montreal. Pouliot adds:

“We see Poly/CSAM as a way to strengthen Canada’s industrial leadership in cold spray additive manufacturing and becoming more agile and competitive on the national and international scene.”

Canada’s additive manufacturing expertise

The aim of the NRC is to turn research into beneficial products for the commercial market. Working closely with industry, the council prioritizes areas of interest based on those that will help provide “creative, relevant and sustainable solutions” to the nation’s “current and future economic, social and environmental challenges.”

Identifying additive manufacturing as one area of interest, the council is already supporting several initiatives. Together with GE Additive’s AP&C the NRC has developed a new method of analyzing metal powders for additive manufacturing. The council has also given a DED development license to 3D printing service bureau Burloak Technologies. And, since February 2019, the NRC has been working with Aspect Biosystems to develop a 3D bioprinted blood-brain barrier to study the effects of new medicines.

With the new CSAM focus, the NRC moves further into the industrial additive manufacturing sector, developing solutions to benefits automotive, aerospace and transport industries. “The National Research Council of Canada acknowledges the value and importance this collaboration can offer the industry and the Canadian advanced manufacturing ecosystem,” comments François Cordeau, VP of Transportation and Manufacturing at the NRC.

“We see great potential in bringing together different stakeholders to enable innovation and to build a network of industrial partners for a stronger Canadian supply and value chain.”

Particular benefits of CSAM include an ability to repair or add to pre-fabricated parts and a fidelity to feedstock materials unattainable through melt-based technologies. As identified by the NRC, CSAM can also help reduce material waste.

Bringing CSAM to the market

Founded in 1982, Polycontrols provides instrumentation, calibration and manufacturing solutions relating to gas and liquid flow. For cold spray in particular, the company supplies powder feeders, controllers and compressors required by both additive manufacturing and plasma-generated powders industry.

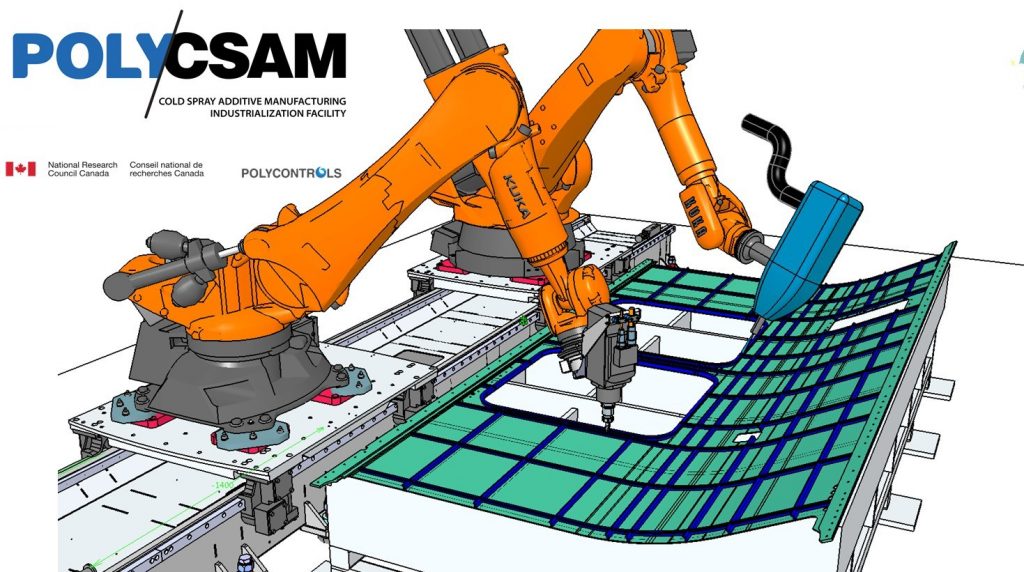

Applying this expertise, Polycontrols will work at the Poly/CSAM facility with the support of 40 NRC experts. In addition to coating and 3D fabrication using cold spray methods, technologies to be provided by the Poly/CSAM facility include surface preparation; local, laser-based thermal treatment; in-situ robotic machining and surface finishing; state-of-the-art sensor technologies; extensive data logging and analytics; and machine learning.

Cordeau concludes, “Our renowned technological expertise and capabilities in additive manufacturing research and development will support Poly/CSAM and contribute to developing demonstration platforms targeted at end user-industries and cluster networks.”

For all of the latest additive manufacturing research news Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows logo of Poly/CSAM, the new metal additive manufacturing facility to open in February 2020. Image via CNW Group/National Research Council Canada