NinjaFlex is one of the more popular 3D printing materials on the market, despite the fact that most desktop 3D printers are not optimized to use it. In their new NinjaFlex Engineer Talk video series, viewers can learn valuable tips, tricks, and troubleshooting techniques to really make their flexible filament easier to use.

The twelve part series isn’t as long as it sounds, with each video generally being about one to two minutes each. They are conveniently broken up into short sections, so you only need to view the videos that are applicable to your printer or needs. The video series provides a great overview of FDM 3D printing, and it does a nice job of going over the challenges that you may encounter when using NinjaFlex and the best ways to mitigate them.

Because most 3D printers are optimized for harder 3D printing materials, like PLA or ABS, NinjaFlex can often get jammed in the drive wheel, if it’s too far away from the hot end. While just about every 3D printer that has this problem has a solution somewhere online, the video series covers ways to minimize the problem on several of the more popular desktop 3D printers, such as the LulzBot TAZ, MakerBot Replicator and LeapFrog Creatr.

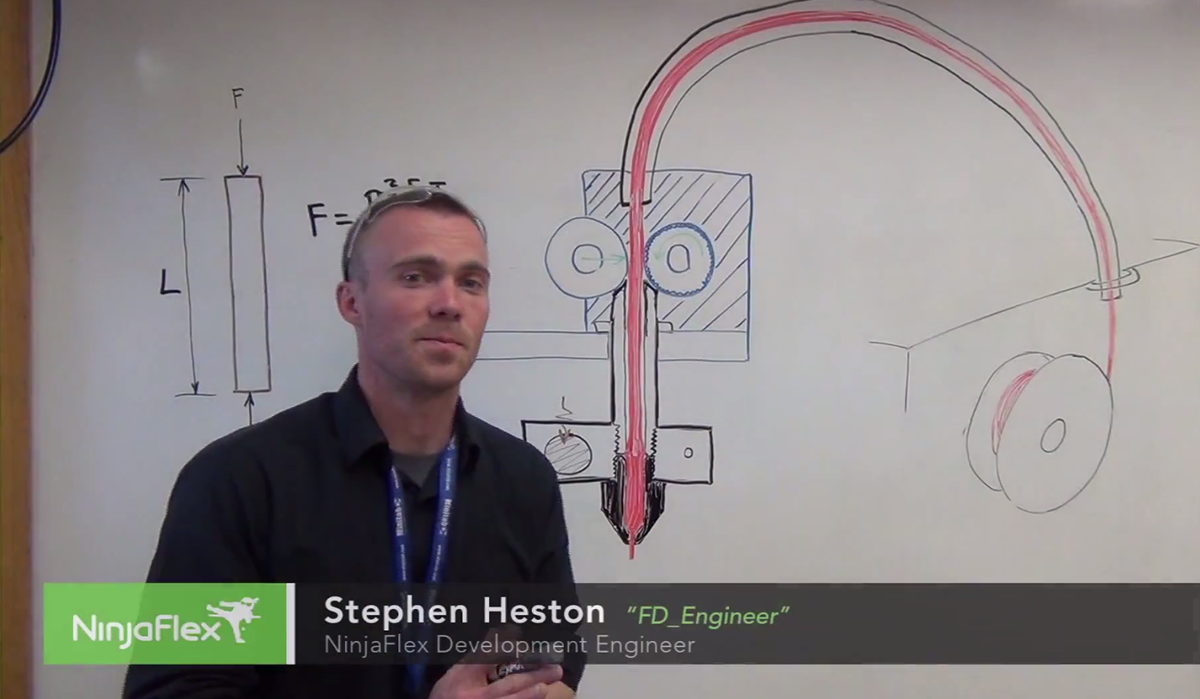

The series is hosted by Stephen Heston, an engineer from NinjaFlex manufacturer Fenner Drives, who does a pretty great job of boiling rather complicated, technical concepts down into easy-to-understand explanations. He covers everything from the best way to optimize your filament guide tube placement to make sure your NinjaFlex doesn’t get stuck to the best way to avoid common extruder jams and issues.

You can see the entire YouTube series here and you can watch the Introduction video embedded below:

While the issue of a material not working on some 3D printer models isn’t unique to NinjaFlex, Fenner Drives is getting out in front of it and trying to educate an eager market on the best way to use their product. It’s a refreshing attitude that I wish more companies in the 3D printing industry would adopt. I’ve found that a lot of companies often assume that anyone who buys a 3D printer is basically an engineer, so the technology is rarely explained in terms that a layman might understand. Outreach like this is probably why NinjaFlex is the most popular flexible 3D printing material on the market and it is certainly why I have little doubt that that will change anytime soon.